Plate thickness refers to the actual measured thickness of a metal plate used in construction or manufacturing, while scantling thickness is the minimum required thickness specified by design codes or standards to ensure structural integrity and safety. Ensuring your plate meets or exceeds the scantling thickness is crucial for compliance and performance in engineering applications.

Table of Comparison

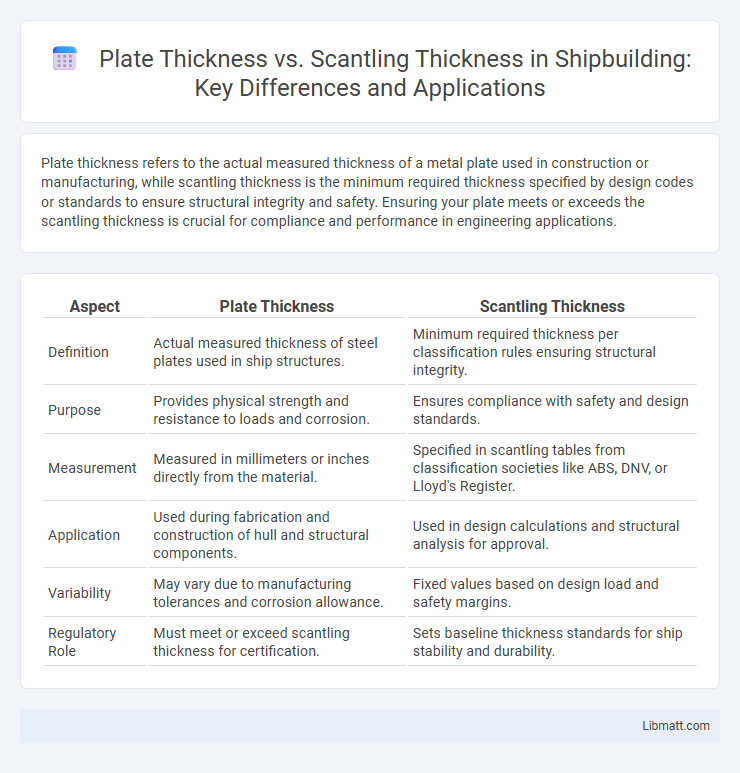

| Aspect | Plate Thickness | Scantling Thickness |

|---|---|---|

| Definition | Actual measured thickness of steel plates used in ship structures. | Minimum required thickness per classification rules ensuring structural integrity. |

| Purpose | Provides physical strength and resistance to loads and corrosion. | Ensures compliance with safety and design standards. |

| Measurement | Measured in millimeters or inches directly from the material. | Specified in scantling tables from classification societies like ABS, DNV, or Lloyd's Register. |

| Application | Used during fabrication and construction of hull and structural components. | Used in design calculations and structural analysis for approval. |

| Variability | May vary due to manufacturing tolerances and corrosion allowance. | Fixed values based on design load and safety margins. |

| Regulatory Role | Must meet or exceed scantling thickness for certification. | Sets baseline thickness standards for ship stability and durability. |

Introduction to Plate Thickness and Scantling Thickness

Plate thickness refers to the actual measured thickness of a metal plate used in construction or manufacturing, while scantling thickness is the minimum thickness required by design codes and standards to ensure structural integrity. Understanding the difference between plate thickness and scantling thickness is essential for Your project's compliance with safety regulations and durability requirements. Engineers must carefully evaluate both to optimize material use without compromising strength or stability.

Understanding Key Terminologies

Plate thickness refers to the actual measured thickness of a steel plate used in shipbuilding or structural applications, while scantling thickness is the minimum required thickness determined by design standards and load calculations. Understanding the difference ensures your structure meets safety and regulatory requirements without unnecessary material use. Recognizing these terminologies helps optimize both cost-efficiency and structural integrity in engineering projects.

Plate Thickness: Definition and Application

Plate thickness refers to the actual measured thickness of a metal sheet used in structural applications, typically specified in millimeters or inches. It plays a crucial role in determining the strength, durability, and load-bearing capacity of steel structures, impacting both manufacturing and safety standards. Your choice of plate thickness directly affects the structural integrity and compliance with industry regulations in shipbuilding, construction, and engineering projects.

Scantling Thickness: Definition and Usage

Scantling thickness refers to the minimum required thickness of structural plates or components specified in shipbuilding and marine engineering to ensure safety and strength under designated load conditions. It is a calculated value based on standards such as the International Maritime Organization (IMO) rules or classification society guidelines, taking into account factors like material properties, stress, corrosion allowance, and load types. Understanding scantling thickness helps you accurately design and inspect ship hulls, ensuring compliance and structural integrity beyond just the measured plate thickness.

Standards and Codes Governing Thickness Selection

Standards and codes such as the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code and the International Maritime Organization (IMO) define guidelines for plate thickness and scantling thickness selection to ensure structural integrity and safety. Plate thickness is typically influenced by factors like load requirements and corrosion allowance, while scantling thickness incorporates additional stiffening elements and manufacturing tolerances as specified in classification society rules like ABS, DNV GL, and Lloyd's Register. Precise compliance with these standards prevents structural failures and optimizes material use in shipbuilding and pressure vessel fabrication.

Comparing Plate Thickness vs Scantling Thickness

Plate thickness refers to the actual measured thickness of a steel plate used in shipbuilding or structural applications, while scantling thickness accounts for the minimum required thickness including allowances for corrosion, wear, and fabrication tolerances. Comparing plate thickness vs scantling thickness ensures that structural components meet design safety standards and regulatory requirements without excessive material usage. Your accurate assessment of these thicknesses optimizes durability and cost-efficiency in engineering projects.

Impact on Structural Integrity and Safety

Plate thickness directly influences the structural integrity by determining the load-bearing capacity and resistance to stress, while scantling thickness, defined by design codes, ensures standardized minimum dimensions for safety and durability. Thicker plates enhance durability and reduce the risk of failure due to fatigue or corrosion, while proper scantling thickness guarantees compliance with safety regulations and uniform distribution of stresses. Neglecting the balance between plate and scantling thickness can lead to structural weaknesses, compromising overall safety in engineering applications.

Material Selection and Thickness Optimization

Material selection directly influences plate thickness requirements, as higher-strength materials often allow for reduced scantling thickness while maintaining structural integrity. Thickness optimization involves balancing the mechanical properties of the chosen material with factors such as corrosion allowance and load conditions. Engineers use material data and design codes to determine the minimum plate thickness that meets safety standards without excessive weight or cost.

Common Industry Practices and Case Studies

Common industry practices distinguish plate thickness as the actual measured dimension of a flat metal sheet, while scantling thickness refers to the structural thickness specified in design codes for strength and durability. Case studies in shipbuilding highlight discrepancies where using plate thickness alone led to underestimations of structural capacity, prompting revisions to scantling thickness criteria to ensure safety margins. Adoption of standardized scantling thickness calculations aligns with classification society requirements, improving accuracy in structural assessments and minimizing material weight without compromising vessel integrity.

Conclusion: Choosing the Right Thickness for Your Project

Selecting the appropriate plate thickness over scantling thickness depends on the specific structural requirements and load conditions of your project. Plate thickness directly influences the durability and strength of materials exposed to stress and corrosion, while scantling thickness considers overall framework dimensions and regulatory standards. Your decision should balance these factors to ensure safety, compliance, and optimal performance in maritime or construction applications.

Plate thickness vs scantling thickness Infographic

libmatt.com

libmatt.com