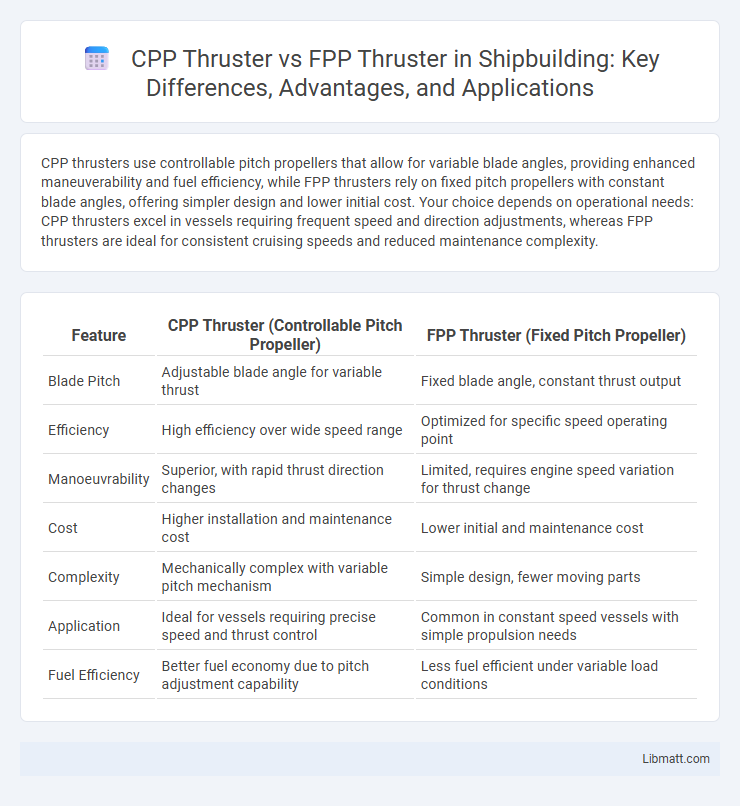

CPP thrusters use controllable pitch propellers that allow for variable blade angles, providing enhanced maneuverability and fuel efficiency, while FPP thrusters rely on fixed pitch propellers with constant blade angles, offering simpler design and lower initial cost. Your choice depends on operational needs: CPP thrusters excel in vessels requiring frequent speed and direction adjustments, whereas FPP thrusters are ideal for consistent cruising speeds and reduced maintenance complexity.

Table of Comparison

| Feature | CPP Thruster (Controllable Pitch Propeller) | FPP Thruster (Fixed Pitch Propeller) |

|---|---|---|

| Blade Pitch | Adjustable blade angle for variable thrust | Fixed blade angle, constant thrust output |

| Efficiency | High efficiency over wide speed range | Optimized for specific speed operating point |

| Manoeuvrability | Superior, with rapid thrust direction changes | Limited, requires engine speed variation for thrust change |

| Cost | Higher installation and maintenance cost | Lower initial and maintenance cost |

| Complexity | Mechanically complex with variable pitch mechanism | Simple design, fewer moving parts |

| Application | Ideal for vessels requiring precise speed and thrust control | Common in constant speed vessels with simple propulsion needs |

| Fuel Efficiency | Better fuel economy due to pitch adjustment capability | Less fuel efficient under variable load conditions |

Introduction to Marine Thrusters

CPP (Controllable Pitch Propeller) thrusters offer adjustable blade angles for enhanced maneuverability and efficiency in varying speed conditions, making them ideal for dynamic marine operations. In contrast, FPP (Fixed Pitch Propeller) thrusters have a set blade angle, providing robust performance and simplicity but less flexibility in speed and thrust control. Marine thrusters like CPP and FPP are critical for vessel propulsion and maneuvering, directly impacting fuel efficiency, operational control, and vessel responsiveness in different maritime environments.

What is a CPP (Controllable Pitch Propeller) Thruster?

A CPP (Controllable Pitch Propeller) thruster features blades that can adjust their pitch angle to optimize thrust and efficiency across varying speeds and load conditions. This adaptability allows for enhanced maneuverability and fuel savings compared to Fixed Pitch Propeller (FPP) thrusters, which have blades set at a constant angle. You benefit from precise control and improved performance in demanding marine operations when using CPP thrusters.

What is an FPP (Fixed Pitch Propeller) Thruster?

An FPP (Fixed Pitch Propeller) thruster features blades set at a constant angle, providing reliable and straightforward propulsion for vessels. It is ideal for operations requiring consistent thrust without the need for complex adjustments, offering durability and simplified maintenance compared to variable pitch systems. FPP thrusters are commonly used in tugboats, workboats, and ferries where predictable performance and robustness are crucial.

Key Differences Between CPP and FPP Thrusters

CPP (Controllable Pitch Propeller) thrusters feature adjustable blade angles allowing for variable thrust direction and efficient speed control without changing engine RPM, enhancing maneuverability and fuel efficiency. FPP (Fixed Pitch Propeller) thrusters have fixed blade angles, relying on engine speed variation to regulate thrust, which simplifies design but limits responsiveness and fuel optimization. Key differences include CPP's superior directional control, improved efficiency at varying speeds, and greater complexity compared to FPP's simpler, cost-effective design with less precise thrust management.

Advantages of CPP Thrusters

CPP thrusters provide precise thrust control and efficiency benefits, especially in vessels requiring variable speed operations. Their ability to adjust blade pitch allows for improved fuel economy and reduced cavitation compared to fixed pitch propeller (FPP) thrusters. CPP thrusters offer enhanced maneuverability and quicker response times, making them ideal for dynamic positioning and complex navigational tasks.

Benefits of FPP Thrusters

FPP thrusters offer enhanced fuel efficiency and longer operational lifespans compared to CPP thrusters, due to their fixed pitch design reducing mechanical complexity and maintenance needs. They provide better reliability in steady cruising conditions and lower vibration levels, which contribute to increased comfort and reduced wear on your vessel. Lower upfront and lifecycle costs make FPP thrusters an economical choice for ships with consistent speed requirements and straightforward propulsion demands.

Operational Efficiency: CPP vs FPP

CPP thrusters provide superior operational efficiency by allowing continuous and adjustable pitch control, enabling optimal thrust and fuel consumption across varying speeds and loads. FPP thrusters maintain fixed blade angles, limiting efficiency to a narrow range of operating conditions and often leading to increased fuel usage during off-design speeds. You benefit from CPP's adaptability, which maximizes propulsion efficiency and reduces overall operational costs compared to FPP systems.

Maintenance and Lifecycle Costs

CPP thrusters typically incur higher initial maintenance costs due to their complex pitch control mechanisms but offer longer operational lifecycles as pitch adjustments optimize fuel efficiency and reduce wear. FPP thrusters generally have lower maintenance expenses with simpler fixed blades but may result in increased fuel consumption and shorter overall lifespan due to less adaptability in varying conditions. Your choice impacts long-term operational expenditure, where CPP thrusters provide cost savings through enhanced efficiency and reduced downtime, despite higher upfront upkeep.

Application Suitability: When to Choose CPP or FPP?

CPP thrusters excel in applications requiring precise speed control and frequent maneuvering, making them ideal for vessels like tugboats, dredgers, and offshore supply ships. FPP thrusters are better suited for applications prioritizing fuel efficiency at constant speeds, such as bulk carriers, tankers, and container ships on long-haul routes. You should choose CPP when variable thrust and rapid response are critical, while FPP is preferable for straightforward, steady-speed operations.

Summary: Which Thruster Is Right for Your Vessel?

CPP thrusters offer variable pitch propellers that enhance maneuverability and fuel efficiency, making them ideal for vessels requiring precise speed control and frequent directional changes. FPP thrusters utilize fixed pitch propellers, delivering reliable thrust and simplicity at a lower upfront cost, suited for vessels with consistent speed demands and straightforward operational profiles. Your choice depends on the vessel's operational needs, with CPP thrusters favoring versatility and efficiency, while FPP thrusters provide cost-effective, dependable performance.

CPP thruster vs FPP thruster Infographic

libmatt.com

libmatt.com