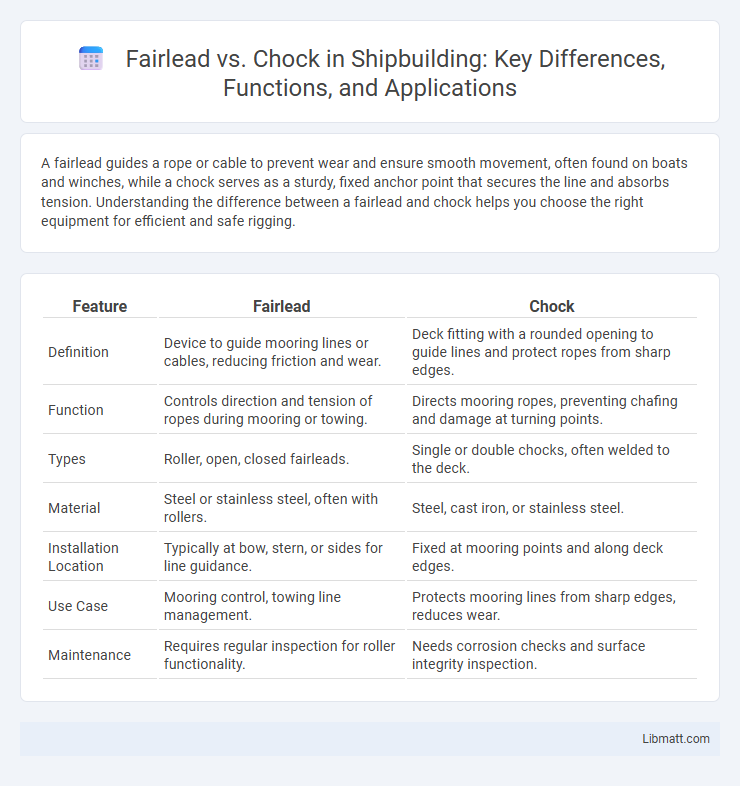

A fairlead guides a rope or cable to prevent wear and ensure smooth movement, often found on boats and winches, while a chock serves as a sturdy, fixed anchor point that secures the line and absorbs tension. Understanding the difference between a fairlead and chock helps you choose the right equipment for efficient and safe rigging.

Table of Comparison

| Feature | Fairlead | Chock |

|---|---|---|

| Definition | Device to guide mooring lines or cables, reducing friction and wear. | Deck fitting with a rounded opening to guide lines and protect ropes from sharp edges. |

| Function | Controls direction and tension of ropes during mooring or towing. | Directs mooring ropes, preventing chafing and damage at turning points. |

| Types | Roller, open, closed fairleads. | Single or double chocks, often welded to the deck. |

| Material | Steel or stainless steel, often with rollers. | Steel, cast iron, or stainless steel. |

| Installation Location | Typically at bow, stern, or sides for line guidance. | Fixed at mooring points and along deck edges. |

| Use Case | Mooring control, towing line management. | Protects mooring lines from sharp edges, reduces wear. |

| Maintenance | Requires regular inspection for roller functionality. | Needs corrosion checks and surface integrity inspection. |

Introduction to Fairleads and Chocks

Fairleads and chocks are essential maritime hardware used to guide ropes, cables, and lines on ships and docks, preventing excessive wear and ensuring safe handling. Fairleads typically feature smooth, rounded openings or rollers that reduce friction and allow controlled movement of lines, while chocks are sturdy, fixed fittings designed to secure ropes by providing strong directional support and anchoring points. Understanding their structural differences and applications is critical for optimizing mooring operations and enhancing vessel safety.

Definition and Purpose of Fairleads

Fairleads are devices used on boats and ships to guide ropes or cables, preventing them from rubbing against surfaces and reducing wear and tear. Unlike chocks, which are typically rigid metal or plastic fittings designed to provide a smooth passage for ropes, fairleads often include rollers or smooth edges to minimize friction. Understanding the definition and purpose of fairleads helps you choose the right equipment for efficient and safe line handling in maritime applications.

Definition and Purpose of Chocks

Chocks are sturdy, fixed devices used on ships and docks to guide and protect mooring lines by preventing excessive wear and safeguarding the vessel's structure. They serve to control the direction of ropes and cables, ensuring safe and efficient mooring operations by reducing friction and potential damage. Unlike fairleads, which are often movable or adjustable, chocks are rigid fittings designed primarily for durability and secure line management.

Key Differences Between Fairleads and Chocks

Fairleads guide ropes or lines aboard vessels, preventing wear and controlling direction, while chocks serve as fixed fittings designed to protect and support mooring lines under tension. The key differences lie in their function and design: fairleads typically have rollers or holes to redirect lines smoothly, whereas chocks are solid structures that provide a strong, abrasion-resistant passage. Understanding these distinctions ensures your marine equipment selection enhances safety and efficiency during ship mooring operations.

Types of Fairleads Used in Marine Applications

Roller fairleads, commonly used in marine applications, reduce friction and wear on ropes by guiding them smoothly during mooring and towing operations. Fixed fairleads, such as hawse pipes and open fairleads, provide simple, sturdy direction points primarily for anchor chains and heavy lines, ensuring secure line control. Sliding fairleads offer adjustable positioning for various line angles, enhancing flexibility and efficiency in complex docking or anchoring maneuvers.

Types of Chocks and Their Functions

Chocks are essential maritime fittings designed to guide ropes and cables, preventing wear and ensuring optimal alignment; types include roller chocks that reduce friction for heavy mooring lines, open chocks providing easy access for rope handling, and closed chocks offering enhanced protection by enclosing the rope path. Each chock type serves specific functions: roller chocks minimize abrasion and facilitate movement, open chocks allow quick adjustments, and closed chocks ensure secure, controlled routing of lines under heavy loads. Proper selection of chock type enhances safety and efficiency in vessel mooring operations, directly impacting the longevity of ropes and the stability of the ship.

Material and Construction Comparison

Fairleads are typically made from high-strength steel or aluminum alloys designed to reduce friction and guide ropes or cables smoothly, featuring a smooth or roller-based construction to prevent abrasion. Chocks, on the other hand, are usually fabricated from heavy-duty cast steel or reinforced steel, constructed as solid blocks with a curved or V-shaped opening to securely hold cables in place and withstand high loads. Both components prioritize durability and corrosion resistance, but fairleads emphasize low friction for rope management while chocks focus on secure cable holding under heavy tension.

Installation Considerations for Both Fixtures

Fairleads require precise alignment with the vessel's deck to minimize line friction and wear, often necessitating reinforced mounting points made from high-strength materials like steel or aluminum. Chocks demand robust installation with secure welding or bolting to withstand heavy loads and dynamic forces, ensuring safe line guidance through a fixed opening. Your choice should factor in available deck space, load requirements, and ease of maintenance to optimize performance and longevity.

Performance and Safety Aspects

Fairleads enhance rope performance by reducing friction and wear, ensuring smoother line handling and increased durability during heavy loads. Chocks provide superior safety by securely guiding ropes through fixed openings, preventing slippage and maintaining proper alignment under dynamic conditions. Your choice between fairlead and chock impacts operational efficiency and crew safety, making it crucial to match the equipment to specific marine or industrial applications.

Choosing Between Fairlead and Chock: Factors to Consider

Selecting between a fairlead and a chock depends on your vessel type and the load capacity required for guiding ropes or cables. Fairleads are ideal for reducing friction and wear on lines during changes in direction, while chocks provide robust support by firmly securing cables along the deck edges. Consider factors such as line diameter, rope material, and the importance of minimizing abrasion to make the best choice for your maritime operations.

Fairlead vs chock Infographic

libmatt.com

libmatt.com