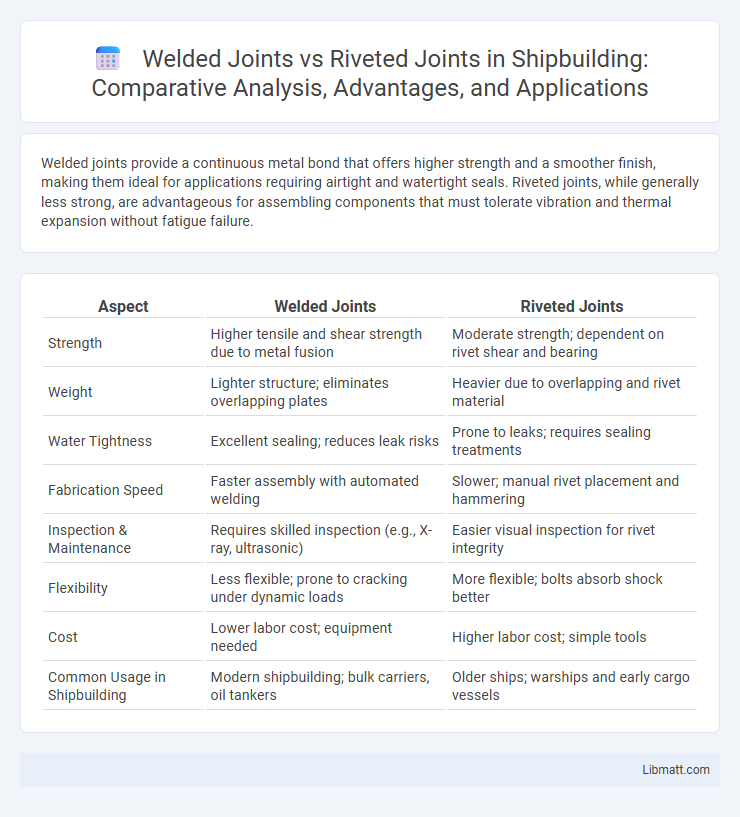

Welded joints provide a continuous metal bond that offers higher strength and a smoother finish, making them ideal for applications requiring airtight and watertight seals. Riveted joints, while generally less strong, are advantageous for assembling components that must tolerate vibration and thermal expansion without fatigue failure.

Table of Comparison

| Aspect | Welded Joints | Riveted Joints |

|---|---|---|

| Strength | Higher tensile and shear strength due to metal fusion | Moderate strength; dependent on rivet shear and bearing |

| Weight | Lighter structure; eliminates overlapping plates | Heavier due to overlapping and rivet material |

| Water Tightness | Excellent sealing; reduces leak risks | Prone to leaks; requires sealing treatments |

| Fabrication Speed | Faster assembly with automated welding | Slower; manual rivet placement and hammering |

| Inspection & Maintenance | Requires skilled inspection (e.g., X-ray, ultrasonic) | Easier visual inspection for rivet integrity |

| Flexibility | Less flexible; prone to cracking under dynamic loads | More flexible; bolts absorb shock better |

| Cost | Lower labor cost; equipment needed | Higher labor cost; simple tools |

| Common Usage in Shipbuilding | Modern shipbuilding; bulk carriers, oil tankers | Older ships; warships and early cargo vessels |

Introduction to Welded and Riveted Joints

Welded joints create a continuous metal bond by melting and fusing materials, offering high strength and seamless integration in fabrication. Riveted joints rely on mechanical fastening with metal pins or rivets, providing reliable connections suitable for dynamic loads and easy inspection. Understanding these fundamental differences is essential for selecting the appropriate joint type in structural and manufacturing applications.

Basic Definitions and Principles

Welded joints involve the fusion of metal parts through heat application, creating a continuous and strong bond without additional fasteners. Riveted joints connect components using metal pins or bolts, mechanically fastening materials by deforming the rivet to hold the parts together. Welding provides a seamless connection ideal for high-stress applications, while riveting offers reliable fastening suitable for structures requiring disassembly or vibration resistance.

Types of Welded Joints

Butt, lap, corner, edge, and T-joints are common types of welded joints used in metal fabrication, each designed for specific structural needs. Welded joints provide strong, continuous connections by fusing metal pieces together, offering better load distribution compared to riveted joints. Your project's strength and durability depend on selecting the appropriate welded joint type for optimal performance.

Types of Riveted Joints

Riveted joints primarily include lap joints, butt joints with single or double cover plates, and chain riveted or zigzag riveted patterns, each designed for specific mechanical strength and load distribution. Lap joints are widely used for connecting two overlapping plates, while butt joints with cover plates provide added reinforcement at edges. Understanding these types helps you select the best riveted joint for your structural or mechanical applications, ensuring reliability and durability.

Strength and Load Distribution

Welded joints provide superior strength and more uniform load distribution compared to riveted joints, as the continuous metal fusion minimizes stress concentrations. Riveted joints, relying on discrete mechanical fasteners, tend to create localized stresses around each rivet, which can reduce overall joint efficiency. Your choice between these methods should consider the required load capacity and the structural integrity needed for the application.

Durability and Maintenance

Welded joints offer superior durability due to their continuous bond that withstands high stress and environmental factors better than riveted joints. Maintenance of welded joints is generally lower since they have fewer points of potential failure, unlike riveted joints that require regular inspection and tightening of individual rivets. The absence of gaps in welded joints reduces corrosion risk, enhancing longevity and reducing the need for frequent repairs.

Fabrication and Installation Process

Welded joints require precise preparation, including edge cleaning and positioning, followed by heating with specialized equipment to fuse metal parts, resulting in a continuous and strong bond. Riveted joints involve drilling holes and installing metal rivets that are mechanically deformed to clamp parts together, typically requiring less specialized equipment but more manual labor. The fabrication of welded joints demands skilled operators and controlled environments, while riveted connections allow for easier inspection and disassembly during installation.

Cost Considerations

Welded joints typically offer lower labor costs and faster assembly times compared to riveted joints, making them more cost-effective for large-scale production. Riveted joints require more skilled labor, specialized tools, and longer installation times, increasing overall project expenses. Your decision on joint type can significantly impact budget efficiency, especially in industries where material and labor costs are critical factors.

Applications in Industry

Welded joints are extensively used in industries such as construction, shipbuilding, and automotive manufacturing due to their high strength and ability to create continuous, leak-proof connections. Riveted joints are common in aerospace, bridges, and heavy machinery where vibration resistance and ease of inspection are critical. The choice between welded and riveted joints depends on factors like load requirements, material type, and maintenance needs in specific industrial applications.

Pros and Cons Comparison

Welded joints offer higher strength, better load distribution, and a smoother surface finish, making them ideal for pressure vessels and structural applications, but they require skilled labor and can be susceptible to defects like cracks and residual stresses. Riveted joints provide reliable mechanical fastening without heat, allowing for easy inspection and repair, yet they add weight and create stress concentrations that may reduce fatigue life. Choosing between welded and riveted joints depends on factors such as material type, load conditions, ease of assembly, and maintenance requirements.

Welded joints vs riveted joints Infographic

libmatt.com

libmatt.com