Float-on float-off (Flo-Flo) ships transport cargo by submerging their decks to float cargo on or off, ideal for heavy, oversized loads like oil rigs. Lift-on lift-off (Lo-Lo) vessels use cranes to lift cargo on and off, offering greater flexibility and efficiency for containerized goods.

Table of Comparison

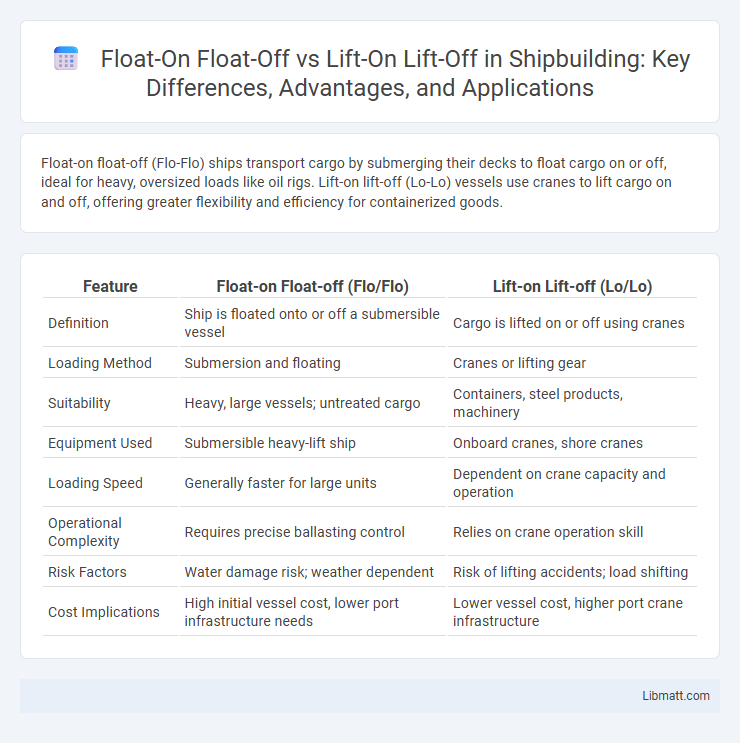

| Feature | Float-on Float-off (Flo/Flo) | Lift-on Lift-off (Lo/Lo) |

|---|---|---|

| Definition | Ship is floated onto or off a submersible vessel | Cargo is lifted on or off using cranes |

| Loading Method | Submersion and floating | Cranes or lifting gear |

| Suitability | Heavy, large vessels; untreated cargo | Containers, steel products, machinery |

| Equipment Used | Submersible heavy-lift ship | Onboard cranes, shore cranes |

| Loading Speed | Generally faster for large units | Dependent on crane capacity and operation |

| Operational Complexity | Requires precise ballasting control | Relies on crane operation skill |

| Risk Factors | Water damage risk; weather dependent | Risk of lifting accidents; load shifting |

| Cost Implications | High initial vessel cost, lower port infrastructure needs | Lower vessel cost, higher port crane infrastructure |

Introduction to Float-on Float-off (FLO-FLO) and Lift-on Lift-off (LO-LO)

Float-on Float-off (FLO-FLO) vessels are specialized ships designed for transporting large, heavy cargo by floating it on and off the deck using ballast control, ideal for offshore platforms and heavy machinery. Lift-on Lift-off (LO-LO) vessels use cranes to load and unload containers or cargo, providing flexibility for various port facilities and containerized shipments. Your choice between FLO-FLO and LO-LO depends on cargo size, weight, and available port infrastructure.

Defining Key Concepts: FLO-FLO and LO-LO Shipping Methods

FLO-FLO (Float-on Float-off) ships are specialized vessels designed to transport large cargo such as oil rigs and other floating structures by submerging part of their deck to allow cargo to float on and off, eliminating the need for cranes. LO-LO (Lift-on Lift-off) ships utilize cranes to load and unload containers or heavy goods, relying on lifting equipment at ports or on the vessel itself. These shipping methods differ fundamentally in cargo handling techniques, with FLO-FLO optimized for heavy, waterborne structures and LO-LO suited for containerized and heavy-lift cargo requiring crane operations.

How Float-on Float-off Vessels Operate

Float-on float-off (Flo-Flo) vessels operate by submerging their decks underwater, allowing large cargo such as oil rigs or ships to be floated onto the deck. Once the cargo is positioned, the vessel resurfaces, lifting the cargo out of the water securely for transport. This method differs from lift-on lift-off (Lo-Lo) vessels, which rely on cranes to load and unload cargo, making Flo-Flo ideal for extremely heavy or oversized items that are difficult to lift.

Lift-on Lift-off Shipping: Processes and Equipment

Lift-on Lift-off (LoLo) shipping involves loading and unloading cargo using cranes that lift containers or goods directly onto and off the vessel, enabling efficient handling of unitized cargo. Key equipment includes ship-to-shore gantry cranes, mobile harbor cranes, and specialized lifting gear designed to handle standardized shipping containers and breakbulk cargo. This method enhances port turnaround times, supports precise cargo placement, and is optimal for containerized shipments requiring organized stacking and secure handling.

Comparative Advantages of FLO-FLO vs LO-LO

Float-on float-off (FLO-FLO) vessels excel in handling extremely heavy and oversized cargo by submerging and allowing cargo to float directly on and off, minimizing lifting equipment needs and reducing risk of damage. Lift-on lift-off (LO-LO) ships rely on cranes for loading and unloading containers, enabling faster turnaround times and better suitability for standard sized cargo in well-equipped ports. FLO-FLO maximizes efficiency for project cargo and large industrial components, while LO-LO offers flexibility and speed in containerized shipping operations.

Limitations and Challenges of Each Method

Float-on float-off (Flo-Flo) vessels face limitations like dependency on calm sea conditions and specialized heavy-lift barges, restricting operations in rough weather or shallow waters. Lift-on lift-off (Lo-Lo) methods encounter challenges including crane capacity limits, port infrastructure requirements, and longer loading times for oversized cargo. Your choice must balance operational flexibility against these constraints to optimize transport efficiency and safety.

Suitable Cargo Types for FLO-FLO and LO-LO

Float-on float-off (FLO-FLO) vessels are ideal for transporting heavy, oversized cargo such as oil rigs, large industrial equipment, and naval ships that can be floated directly on and off the ship. Lift-on lift-off (LO-LO) vessels specialize in containerized cargo and standard shipping containers, utilizing cranes to load and unload goods efficiently at ports. Your choice between FLO-FLO and LO-LO depends on cargo size, weight, and the availability of port infrastructure to handle specialized loading methods.

Cost Implications and Efficiency Comparison

Float-on float-off (Flo-Flo) vessels often incur higher initial costs due to specialized ship design and heavy-lift equipment but enable efficient transport of heavy and oversized cargo without extensive port infrastructure. Lift-on lift-off (Lo-Lo) operations generally have lower vessel costs and faster cargo handling times in well-equipped ports, promoting greater efficiency for standardized containerized goods. Cost implications favor Lo-Lo for routine cargo transport, while Flo-Flo offers efficiency advantages for specialized, high-value, or heavy-lift shipments requiring minimal port modification.

Environmental and Safety Considerations

Float-on float-off (Flo-Flo) vessels minimize environmental impact by reducing the need for heavy lifting equipment, lowering the risk of accidents associated with crane operations and minimizing oil spill potential. Lift-on lift-off (Lo-Lo) methods rely on cranes that pose higher risks of mechanical failure and oil leaks, increasing environmental hazards and safety concerns for workers. Flo-Flo operations typically provide safer cargo transfer for heavy and oversized loads by floating them directly onto specialized vessels, enhancing operational safety and reducing environmental footprint.

Choosing the Right Method: Practical Applications and Case Studies

Choosing between Float-on Float-off (Flo/Flo) and Lift-on Lift-off (Lo/Lo) methods depends on your cargo type, project scope, and port facilities. Flo/Flo is ideal for heavy, oversized loads like offshore platforms, where vessels submerge to allow cargo to float on or off, minimizing the need for cranes. Lo/Lo suits more versatile operations with containerized or palletized cargo, utilizing onboard or shore-based cranes for efficient loading and unloading in well-equipped ports.

Float-on float-off vs lift-on lift-off Infographic

libmatt.com

libmatt.com