A piping manifold is a system of pipes designed to distribute fluids or gases efficiently within a facility, focusing on internal flow control and connection points. Your choice between a piping manifold and a cargo manifold depends on the application, as a cargo manifold is specifically engineered for transferring liquids or gases to and from storage tanks on ships or terminals, emphasizing safe and efficient loading and unloading processes.

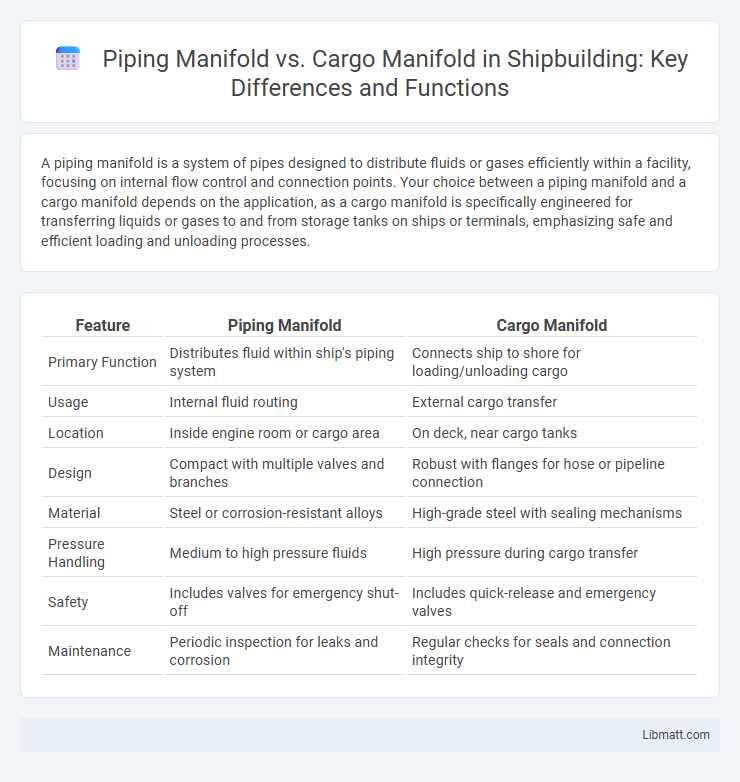

Table of Comparison

| Feature | Piping Manifold | Cargo Manifold |

|---|---|---|

| Primary Function | Distributes fluid within ship's piping system | Connects ship to shore for loading/unloading cargo |

| Usage | Internal fluid routing | External cargo transfer |

| Location | Inside engine room or cargo area | On deck, near cargo tanks |

| Design | Compact with multiple valves and branches | Robust with flanges for hose or pipeline connection |

| Material | Steel or corrosion-resistant alloys | High-grade steel with sealing mechanisms |

| Pressure Handling | Medium to high pressure fluids | High pressure during cargo transfer |

| Safety | Includes valves for emergency shut-off | Includes quick-release and emergency valves |

| Maintenance | Periodic inspection for leaks and corrosion | Regular checks for seals and connection integrity |

Introduction to Piping and Cargo Manifolds

Piping manifolds are essential components in fluid distribution systems, designed to direct the flow between multiple pipelines for efficient operation and maintenance. Cargo manifolds specifically manage the transfer of liquids or gases in shipping and storage facilities, ensuring safe and controlled loading and unloading processes. Understanding the differences in design and function helps optimize Your system's fluid handling efficiency and safety.

Definition of Piping Manifold

A piping manifold is a system of interconnected pipes designed to distribute or collect fluids efficiently within industrial processes, enabling control and regulation of flow rates to multiple destinations. Unlike a cargo manifold, which is specifically used on ships to transfer cargo liquids such as oil or chemicals between storage tanks and shore facilities, a piping manifold is more broadly applied in various industrial settings including HVAC, water treatment, and chemical processing. It facilitates seamless management of fluid flow while maintaining system integrity and operational safety.

Definition of Cargo Manifold

Cargo manifold refers to the system of pipelines, valves, and connections on a vessel designed specifically for the safe and efficient loading and unloading of liquid cargoes. It serves as the central hub linking cargo tanks to shore facilities or other vessels during transfer operations. Your understanding of cargo handling infrastructure improves by distinguishing cargo manifolds from piping manifolds, the latter being broader networks for fluid transport within the ship.

Key Functions of Piping Manifolds

Piping manifolds serve as centralized hubs for fluid distribution, enabling the efficient control and regulation of multiple pipelines within a system. They facilitate the segregation, mixing, and redirection of fluids while ensuring operational safety and minimizing pressure loss. These functions distinguish piping manifolds from cargo manifolds, which primarily focus on the loading and unloading of cargo in marine and industrial applications.

Key Functions of Cargo Manifolds

Cargo manifolds serve as critical junctions in maritime and industrial fluid transfer systems, optimizing the controlled distribution and loading of liquid cargoes such as oil, chemicals, and gases. They enable the safe, efficient connection between ship piping and shore facilities via specialized valves and pipelines, minimizing contamination and ensuring precise flow regulation. Understanding how your cargo manifold operates improves operational safety and enhances transfer reliability during shipping or storage.

Structural Differences Between Piping and Cargo Manifolds

Piping manifolds are designed primarily for fluid distribution within processing systems, featuring multiple branches and valves to control flow across piping networks. Cargo manifolds, installed on tankers or cargo vessels, have robust construction to handle high-pressure loading and unloading of liquids or gases, often incorporating reinforced flanges and specialized valve arrangements to ensure safety during cargo transfer. The structural distinction lies in piping manifolds' emphasis on precise flow regulation within industrial plants, whereas cargo manifolds prioritize durability and containment integrity under dynamic marine conditions.

Applications in Industrial Settings

Piping manifolds serve as central distribution points in industrial systems, directing fluids or gases efficiently across various process lines in sectors like chemical manufacturing and oil refining. Cargo manifolds, specifically designed for marine and transportation industries, facilitate the loading and unloading of liquids such as petroleum products on tankers and barges. Both manifolds optimize flow control and safety, but cargo manifolds are tailored for dynamic environments requiring robust connection systems and pressure management.

Advantages and Disadvantages: Piping Manifold vs. Cargo Manifold

Piping manifolds offer greater flexibility in flow control and easier maintenance due to their standardized design, but they may involve higher initial installation costs and complexity. Cargo manifolds provide direct and efficient transfer of cargo with reduced pressure drops, enhancing operational efficiency; however, they are often customized to specific cargo types, limiting versatility. The choice between piping and cargo manifolds depends on the balance between flexibility, cost, and operational requirements in maritime or industrial applications.

Safety Considerations and Maintenance Practices

Safety considerations for piping manifolds center on preventing leaks and ensuring pressure integrity through regular inspections and using high-quality materials to withstand operational stress. Cargo manifolds require stringent maintenance practices such as frequent testing of seals and valves to avoid contamination and spills during loading or discharge operations. Your maintenance routine should prioritize timely replacement of worn components and adherence to safety protocols to ensure the reliability and safety of both piping and cargo manifolds.

Choosing Between Piping and Cargo Manifolds: Factors to Consider

Choosing between piping manifolds and cargo manifolds depends on the application's pressure requirements, fluid type, and flow control precision. Piping manifolds are ideal for complex piping systems requiring multiple flow paths, commonly used in industrial process control, while cargo manifolds are designed specifically for safe and efficient loading and unloading of liquids on tankers. Material compatibility, operational safety, and ease of maintenance are critical factors influencing the selection between these two manifold types.

Piping manifold vs cargo manifold Infographic

libmatt.com

libmatt.com