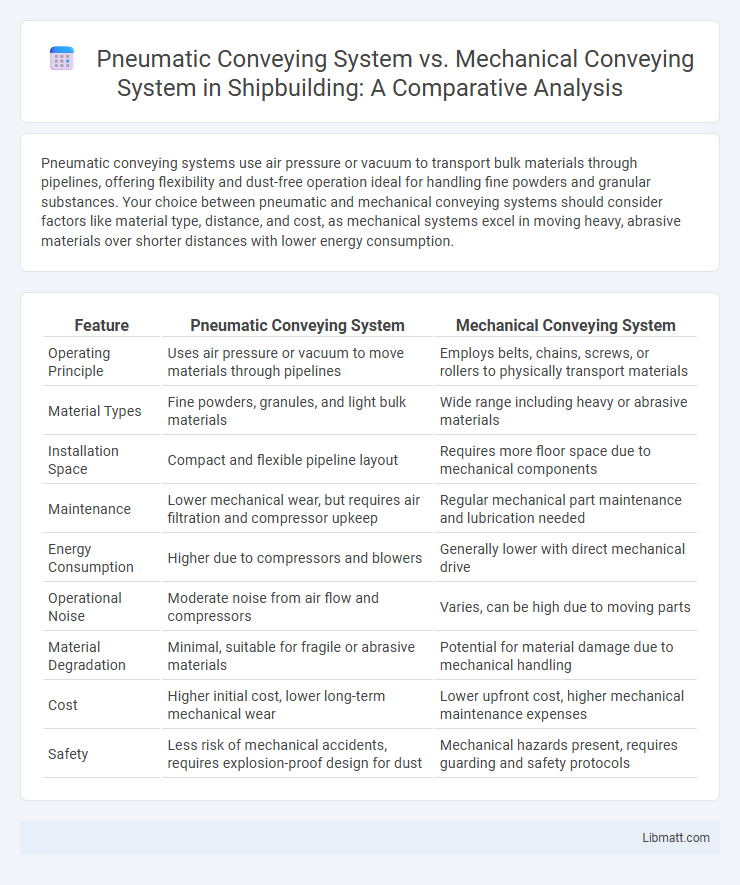

Pneumatic conveying systems use air pressure or vacuum to transport bulk materials through pipelines, offering flexibility and dust-free operation ideal for handling fine powders and granular substances. Your choice between pneumatic and mechanical conveying systems should consider factors like material type, distance, and cost, as mechanical systems excel in moving heavy, abrasive materials over shorter distances with lower energy consumption.

Table of Comparison

| Feature | Pneumatic Conveying System | Mechanical Conveying System |

|---|---|---|

| Operating Principle | Uses air pressure or vacuum to move materials through pipelines | Employs belts, chains, screws, or rollers to physically transport materials |

| Material Types | Fine powders, granules, and light bulk materials | Wide range including heavy or abrasive materials |

| Installation Space | Compact and flexible pipeline layout | Requires more floor space due to mechanical components |

| Maintenance | Lower mechanical wear, but requires air filtration and compressor upkeep | Regular mechanical part maintenance and lubrication needed |

| Energy Consumption | Higher due to compressors and blowers | Generally lower with direct mechanical drive |

| Operational Noise | Moderate noise from air flow and compressors | Varies, can be high due to moving parts |

| Material Degradation | Minimal, suitable for fragile or abrasive materials | Potential for material damage due to mechanical handling |

| Cost | Higher initial cost, lower long-term mechanical wear | Lower upfront cost, higher mechanical maintenance expenses |

| Safety | Less risk of mechanical accidents, requires explosion-proof design for dust | Mechanical hazards present, requires guarding and safety protocols |

Introduction to Bulk Material Conveying Systems

Bulk material conveying systems are essential for transporting powders, granules, and other bulk solids in various industries. Pneumatic conveying systems use airflow to move materials through pipelines, offering flexibility and minimizing contamination risks. Mechanical conveying systems rely on belts, screws, or chains to transport bulk materials, providing high capacity and energy efficiency for heavy or abrasive products.

Overview of Pneumatic Conveying Systems

Pneumatic conveying systems transport bulk materials through pipelines using air or gas flow, offering high-speed, enclosed transfer that reduces contamination and dust emissions. These systems are ideal for handling powders, granules, and friable products in industries like food processing, pharmaceuticals, and cement manufacturing. Compared to mechanical conveying, pneumatic systems provide greater flexibility in routing and automation, with lower maintenance requirements due to fewer moving parts.

Overview of Mechanical Conveying Systems

Mechanical conveying systems utilize components like belts, chains, screws, and rollers to move materials efficiently across various distances and elevations. These systems are ideal for handling bulk solids with high throughput, offering durability and low operational costs in industries such as mining, food processing, and manufacturing. Compared to pneumatic systems, mechanical conveyors provide consistent material flow with less energy consumption and minimal dust generation.

Key Components and Operation Principles

Pneumatic conveying systems use air pressure or vacuum to transport bulk materials through pipelines, with key components including blowers, airlocks, ducts, and receivers, operating on the principle of fluidization and suspension of particles in the airflow. Mechanical conveying systems rely on physical devices such as belts, chains, screws, or buckets to move materials, featuring components like conveyors, pulleys, motors, and rollers, functioning through mechanical motion to transport solids. Understanding these operation principles helps you select the most efficient system for your material handling needs based on factors like throughput, distance, and material characteristics.

Material Suitability and Product Applications

Pneumatic conveying systems excel in transporting fine, powdery, or granular materials such as cement, flour, and plastic pellets, making them ideal for industries like pharmaceuticals, food processing, and chemicals. Mechanical conveying systems are better suited for bulkier, heavy, or abrasive materials such as coal, ore, and grains, serving industries like mining, agriculture, and construction. Material fragility and environmental conditions significantly influence the choice, with pneumatic conveying providing a cleaner, enclosed transport for sensitive or hazardous products, while mechanical conveyors offer high capacity and durability for rugged applications.

Energy Efficiency Comparison

Pneumatic conveying systems generally consume more energy compared to mechanical conveying systems due to the need for air compressors or blowers to move materials through pipelines. Mechanical systems, such as belt or screw conveyors, rely on direct mechanical power, which often results in lower operational energy costs and higher energy efficiency. Your choice between these systems should consider the material type, distance, and energy consumption to optimize overall system efficiency.

Installation and Maintenance Considerations

Pneumatic conveying systems require complex ductwork and sealed piping installations to maintain airtight conditions, often resulting in higher initial installation costs compared to mechanical conveying systems, which utilize straightforward belts, chains, or screw conveyors with simpler setup requirements. Maintenance for pneumatic systems involves monitoring wear on blowers, filters, and the pipeline to prevent blockages and ensure consistent airflow, while mechanical systems demand regular inspection and lubrication of moving parts such as bearings, motors, and conveyor belts to avoid downtime due to mechanical failure. The choice between the two depends heavily on facility layout constraints, desired material handling efficiency, and maintenance resource availability.

Environmental and Safety Aspects

Pneumatic conveying systems offer a cleaner operation with reduced dust emissions, minimizing environmental pollution compared to mechanical conveying systems, which can generate more particulate matter and noise. Pneumatic systems improve workplace safety by enclosing materials within sealed pipelines, lowering the risk of spillage and exposure to hazardous dust, whereas mechanical systems often expose workers to moving parts and potential accidents. Your choice of conveying technology should consider these environmental and safety factors to ensure compliance with regulations and protect worker health.

Cost Analysis and Return on Investment

Pneumatic conveying systems typically involve higher initial capital costs due to complex components like compressors and piping, but offer lower operational costs through energy efficiency and reduced maintenance, leading to a faster return on investment (ROI) in applications requiring flexible, enclosed material handling. Mechanical conveying systems generally have lower upfront expenses, utilizing simpler equipment such as belts or screws, yet incur higher ongoing maintenance costs and energy consumption, potentially extending the payback period. Evaluating project-specific factors, including material characteristics, throughput requirements, and facility layout, is essential to accurately assess cost-effectiveness and ROI between pneumatic and mechanical conveying solutions.

Choosing the Right System: Factors to Consider

Selecting the appropriate conveying system depends on material characteristics, plant layout, and operational requirements. Pneumatic conveying suits fragile, fine, or dusty materials requiring enclosed transport and minimal contamination, while mechanical conveying excels in handling bulk, abrasive, or heavy items with higher energy efficiency. Consider factors such as capacity, distance, maintenance, cost, and flexibility to match the conveying technology to specific industrial applications.

Pneumatic conveying system vs mechanical conveying system Infographic

libmatt.com

libmatt.com