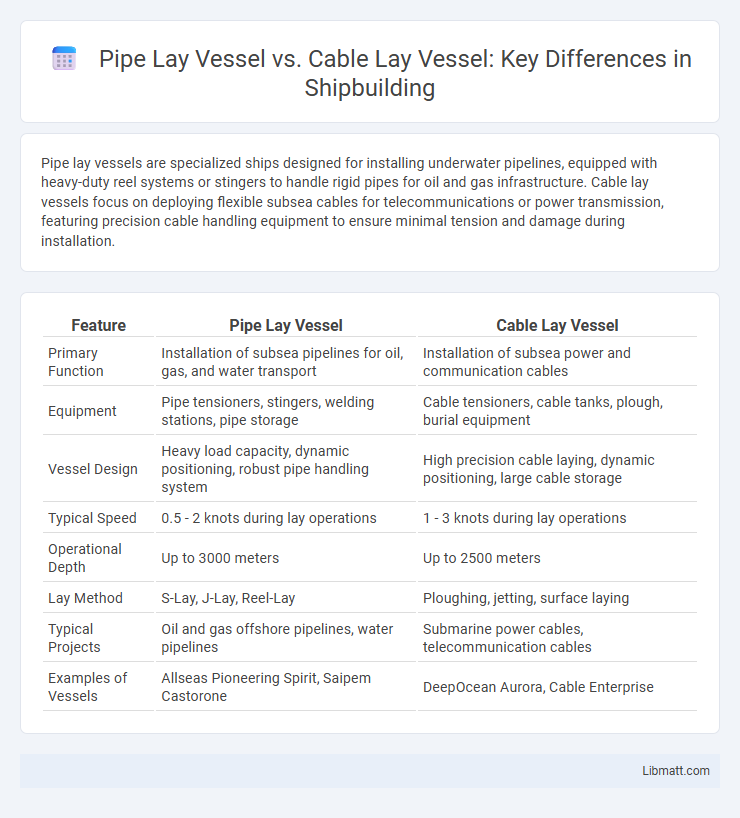

Pipe lay vessels are specialized ships designed for installing underwater pipelines, equipped with heavy-duty reel systems or stingers to handle rigid pipes for oil and gas infrastructure. Cable lay vessels focus on deploying flexible subsea cables for telecommunications or power transmission, featuring precision cable handling equipment to ensure minimal tension and damage during installation.

Table of Comparison

| Feature | Pipe Lay Vessel | Cable Lay Vessel |

|---|---|---|

| Primary Function | Installation of subsea pipelines for oil, gas, and water transport | Installation of subsea power and communication cables |

| Equipment | Pipe tensioners, stingers, welding stations, pipe storage | Cable tensioners, cable tanks, plough, burial equipment |

| Vessel Design | Heavy load capacity, dynamic positioning, robust pipe handling system | High precision cable laying, dynamic positioning, large cable storage |

| Typical Speed | 0.5 - 2 knots during lay operations | 1 - 3 knots during lay operations |

| Operational Depth | Up to 3000 meters | Up to 2500 meters |

| Lay Method | S-Lay, J-Lay, Reel-Lay | Ploughing, jetting, surface laying |

| Typical Projects | Oil and gas offshore pipelines, water pipelines | Submarine power cables, telecommunication cables |

| Examples of Vessels | Allseas Pioneering Spirit, Saipem Castorone | DeepOcean Aurora, Cable Enterprise |

Introduction to Pipe Lay Vessels and Cable Lay Vessels

Pipe lay vessels specialize in installing subsea pipelines for oil and gas transport, equipped with advanced tensioners, reel systems, and dynamic positioning to ensure precise pipe deployment on the seabed. Cable lay vessels focus on laying subsea power and communication cables, featuring specialized cable handling systems, burial tools, and sensor arrays for cable placement accuracy and protection. Both vessel types integrate sophisticated navigation and positioning technology tailored to the unique demands of underwater infrastructure installation.

Key Functions and Applications

Pipe lay vessels specialize in installing pipelines on the seabed for oil, gas, and water transportation, utilizing advanced lowering and welding equipment to ensure secure and continuous pipeline deployment. Cable lay vessels focus on installing subsea cables for telecommunications, power transmission, and offshore wind farms, equipped with precise cable tensioners and dynamic positioning systems to handle delicate cables without damage. Both vessel types play crucial roles in offshore infrastructure, enabling efficient and reliable subsea network installations tailored to their specific materials and operational requirements.

Design Differences and Equipment Features

Pipe lay vessels are specifically designed with heavy-duty cranes, tensioners, and stingers to handle large-diameter pipes for offshore pipeline installation, while cable lay vessels feature specialized cable tanks and dynamic positioning systems optimized for delicate cable deployment. The hull design of pipe lay vessels emphasizes stability to support pipe welding and laying operations under harsh sea conditions, whereas cable lay vessels prioritize maneuverability and advanced cable-handling equipment to prevent damage to sensitive subsea cables. Your choice between these vessels should reflect the project's technical requirements, such as pipe diameter, cable type, and seabed terrain.

Operational Methods: Laying Pipes vs. Laying Cables

Pipe lay vessels utilize stingers and tensioners to install pipelines on the seabed, employing methods such as S-lay, J-lay, or reel-lay to handle heavy steel pipes with precise control. Cable lay vessels deploy subsea cables using carousels or turntables, focusing on continuous, controlled release and burial techniques to ensure protection and integrity. The primary operational distinction lies in pipe lay vessels managing rigid, heavy pipelines requiring structural support, whereas cable lay vessels deal with flexible, sensitive cables necessitating careful handling and burial.

Project Types and Industry Sectors

Pipe lay vessels specialize in subsea pipeline installation projects within the oil and gas industry, supporting offshore production and export infrastructure development. Cable lay vessels focus on deploying subsea power and communication cables for renewable energy sectors such as offshore wind farms and telecommunications networks. Both vessel types are essential for infrastructure projects but cater to different industry sectors and project requirements.

Vessel Capabilities and Limitations

Pipe lay vessels specialize in installing large-diameter subsea pipelines using techniques like S-lay, J-lay, or reel lay, offering high payload capacity and precision for heavy-duty pipeline projects. Cable lay vessels are optimized for deploying communication or power cables with advanced tension control and maneuverability, essential for delicate cable handling but with lower payload compared to pipe lay vessels. Your project requirements must consider these capabilities and limitations to select the most efficient vessel for subsea installation tasks.

Technological Innovations in Lay Vessels

Pipe lay vessels incorporate advanced dynamic positioning systems and automated welding technologies to enhance precision and efficiency in subsea pipeline installation. Cable lay vessels feature cutting-edge tension control and robotic cable handling equipment, optimized for laying delicate subsea communication and power cables. Your project benefits from selecting a vessel equipped with these technological innovations based on the specific requirements of pipe or cable installation.

Safety Protocols and Risk Management

Pipe lay vessels implement rigorous safety protocols including dynamic positioning systems and automated pipe handling equipment to minimize human error during subsea pipeline installation. Cable lay vessels prioritize risk management through advanced tension monitoring and eco-sensitive procedures to protect marine ecosystems and ensure cable integrity. Both vessel types employ comprehensive emergency response plans and continuous crew training to address operational hazards and enhance maritime safety.

Environmental Impact Considerations

Pipe lay vessels typically have a larger environmental footprint due to their heavy equipment and extensive seabed disturbance during pipeline installation. Cable lay vessels, designed for lighter and more flexible cables, often minimize seabed disruption and reduce noise pollution, benefiting marine ecosystems. You should consider the specific environmental sensitivities of the project area when choosing between these vessels.

Future Trends in Offshore Lay Vessel Technology

Future trends in offshore lay vessel technology emphasize automation, enhanced dynamic positioning systems, and eco-friendly propulsion methods to improve efficiency and reduce environmental impact. Pipe lay vessels are increasingly integrating real-time monitoring and AI-driven route optimization to support complex subsea pipeline installations. Your offshore projects will benefit from cable lay vessels adopting lightweight, modular designs and advanced tension control systems, enabling faster deployment of subsea cables for renewable energy and telecommunications.

Pipe lay vessel vs cable lay vessel Infographic

libmatt.com

libmatt.com