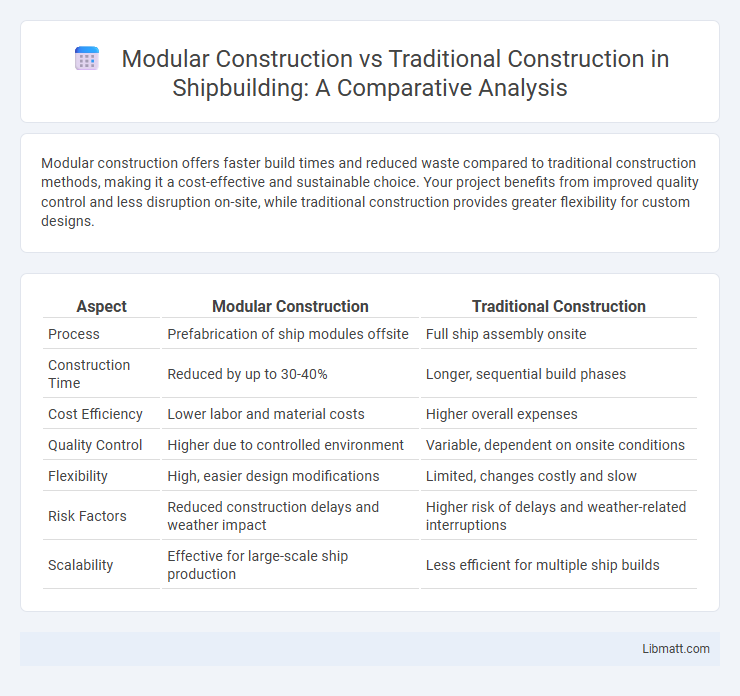

Modular construction offers faster build times and reduced waste compared to traditional construction methods, making it a cost-effective and sustainable choice. Your project benefits from improved quality control and less disruption on-site, while traditional construction provides greater flexibility for custom designs.

Table of Comparison

| Aspect | Modular Construction | Traditional Construction |

|---|---|---|

| Process | Prefabrication of ship modules offsite | Full ship assembly onsite |

| Construction Time | Reduced by up to 30-40% | Longer, sequential build phases |

| Cost Efficiency | Lower labor and material costs | Higher overall expenses |

| Quality Control | Higher due to controlled environment | Variable, dependent on onsite conditions |

| Flexibility | High, easier design modifications | Limited, changes costly and slow |

| Risk Factors | Reduced construction delays and weather impact | Higher risk of delays and weather-related interruptions |

| Scalability | Effective for large-scale ship production | Less efficient for multiple ship builds |

Introduction to Modular and Traditional Construction

Modular construction involves assembling pre-fabricated building sections in a controlled factory environment before transporting them to the site for installation, significantly reducing construction time and waste. Traditional construction relies on building structures entirely on-site using conventional methods, which often leads to longer project durations and greater exposure to weather-related delays. Understanding the differences between these approaches helps you make informed decisions about efficiency, cost, and sustainability in your construction projects.

Key Differences Between Modular and Traditional Construction

Modular construction involves prefabricating building sections in a controlled factory environment, enhancing speed and reducing site disruption compared to traditional construction, which builds entirely on-site. Quality control is more consistent in modular construction due to standardized processes, while traditional methods allow more flexibility in design changes during the build. Cost efficiency favors modular projects through reduced labor and waste, whereas traditional construction can be subject to higher expenses from weather delays and extended timelines.

Speed of Project Delivery

Modular construction significantly accelerates project delivery by enabling simultaneous site preparation and module fabrication, reducing overall build time by up to 50% compared to traditional construction methods. Prefabricated components arrive ready for rapid assembly, minimizing weather-related delays and onsite labor hours. This streamlined process supports faster occupancy and earlier return on investment for developers and owners.

Cost Efficiency Analysis

Modular construction significantly reduces labor costs by up to 20-30% due to off-site fabrication and shorter assembly times, compared to traditional construction methods. Material waste decreases by approximately 50%, contributing to lower overall project expenses and environmental impact. Faster project completion, typically 30-50% quicker, translates into reduced financing and overhead costs, enhancing overall cost efficiency.

Quality Control and Assurance

Modular construction offers enhanced quality control and assurance through factory-based building processes, allowing consistent inspection at every production stage under controlled conditions. Traditional construction often faces variable site conditions, leading to potential quality inconsistencies and longer inspection cycles. The standardized environment of modular construction reduces material waste and defects, ensuring higher precision and adherence to building codes.

Sustainability and Environmental Impact

Modular construction significantly reduces waste by using precise manufacturing processes and recycling excess materials, leading to a lower environmental footprint compared to traditional construction. It typically consumes less energy during the building phase and minimizes site disturbance, which helps preserve natural habitats and reduce pollution. Your choice of modular construction supports sustainability goals by optimizing resource efficiency and decreasing greenhouse gas emissions linked to conventional building methods.

Design Flexibility and Customization

Modular construction offers significant design flexibility and customization by allowing precise factory-built components that can be tailored to your specific architectural needs and easily modified during assembly. Traditional construction provides more on-site adaptability but often encounters longer timelines and higher costs when implementing design changes. Choosing modular construction ensures efficient customization with consistent quality control and faster project delivery.

Labor and Workforce Requirements

Modular construction significantly reduces labor requirements on-site by prefabricating building components in controlled factory environments, allowing for streamlined workflows and less reliance on skilled trades during assembly. Traditional construction demands a larger, highly skilled workforce on-site for extended periods, increasing labor costs and vulnerability to weather delays. The modular approach improves efficiency, reduces workforce-related risks, and accelerates project timelines by shifting much of the labor-intensive work off-site.

Safety Standards and Site Risks

Modular construction enhances safety standards by performing up to 80% of building processes off-site in controlled factory environments, significantly reducing exposure to hazardous site conditions. Traditional construction exposes workers to higher risks such as falls, equipment accidents, and weather-related hazards due to prolonged on-site activities. Adhering to OSHA regulations, modular methods minimize site risks by limiting heavy machinery use and reducing the need for working at heights, resulting in up to 60% fewer job site injuries.

Future Trends in Construction Methods

Modular construction is rapidly evolving with advancements in automation, robotics, and digital twin technology, enabling faster project completion and improved quality control compared to traditional construction methods. Sustainability trends emphasize energy-efficient materials and reduced waste, positioning modular construction as a preferred choice for eco-friendly building solutions. Your future projects can benefit from the scalability and adaptability of modular techniques, which align with smart city development and increased demand for affordable housing.

Modular construction vs traditional construction Infographic

libmatt.com

libmatt.com