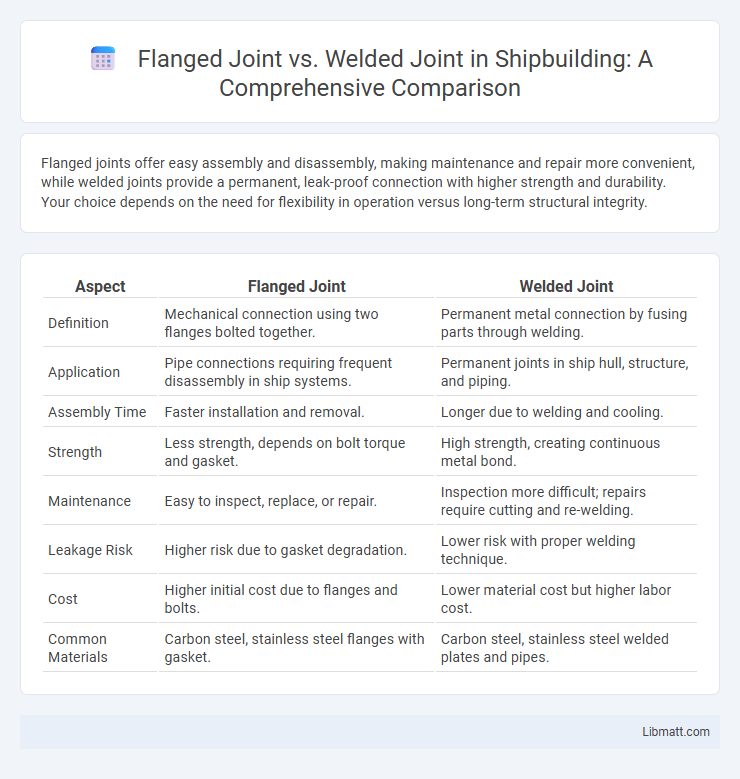

Flanged joints offer easy assembly and disassembly, making maintenance and repair more convenient, while welded joints provide a permanent, leak-proof connection with higher strength and durability. Your choice depends on the need for flexibility in operation versus long-term structural integrity.

Table of Comparison

| Aspect | Flanged Joint | Welded Joint |

|---|---|---|

| Definition | Mechanical connection using two flanges bolted together. | Permanent metal connection by fusing parts through welding. |

| Application | Pipe connections requiring frequent disassembly in ship systems. | Permanent joints in ship hull, structure, and piping. |

| Assembly Time | Faster installation and removal. | Longer due to welding and cooling. |

| Strength | Less strength, depends on bolt torque and gasket. | High strength, creating continuous metal bond. |

| Maintenance | Easy to inspect, replace, or repair. | Inspection more difficult; repairs require cutting and re-welding. |

| Leakage Risk | Higher risk due to gasket degradation. | Lower risk with proper welding technique. |

| Cost | Higher initial cost due to flanges and bolts. | Lower material cost but higher labor cost. |

| Common Materials | Carbon steel, stainless steel flanges with gasket. | Carbon steel, stainless steel welded plates and pipes. |

Introduction to Flanged and Welded Joints

Flanged joints consist of two flanges bolted together with a gasket in between to ensure a tight seal, commonly used for piping systems requiring disassembly and maintenance. Welded joints involve fusing two metal components through processes like butt or fillet welding, providing a permanent, high-strength connection ideal for high-pressure applications. Both joint types serve distinct roles in industrial piping, with flanged joints offering flexibility and welded joints ensuring leak-proof durability.

Definition and Types of Flanged Joints

Flanged joints consist of two flanges connected by bolts, providing a reliable means for assembling pipes, valves, and equipment in fluid handling systems. Common types of flanged joints include slip-on, weld neck, lap joint, socket weld, threaded, and blind flanges, each designed to accommodate different pressure ratings and installation requirements. These joints allow for easy disassembly and maintenance, making them ideal for systems requiring regular inspection or replacement.

Definition and Types of Welded Joints

Welded joints are connections created by fusing metal parts using heat or pressure, forming a strong, permanent bond. Common types of welded joints include butt joints, where two pieces are joined end-to-end; lap joints, which involve overlapping metals; corner joints; edge joints; and T-joints, formed by joining two pieces at a right angle. Understanding these types helps you select the most appropriate welding method compared to flanged joints, which rely on mechanical fastening rather than fusion.

Material Compatibility in Joint Selection

Flanged joints offer greater flexibility in material compatibility, enabling connection between dissimilar metals by using appropriate gaskets and bolts, which accommodates thermal expansion and reduces galvanic corrosion risks. Welded joints require matched or compatible metals to ensure a strong, homogeneous bond and prevent defects such as cracking or corrosion at the weld interface. Your choice depends on balancing mechanical strength needs and material properties for durability and performance in specific applications.

Installation Process: Flanged vs Welded Joints

Flanged joints offer a simpler installation process, requiring bolting pre-fabricated flanges and gaskets, which minimizes on-site welding and enables easier disassembly for maintenance. Welded joints demand precise welding techniques and inspection to ensure joint integrity, involving higher skill levels and longer installation times due to post-weld heat treatment and testing. The flanged joint installation is generally faster and more flexible, while welded joints provide a permanent, leak-proof connection ideal for high-pressure systems.

Strength and Reliability Comparison

Flanged joints offer moderate strength with ease of assembly and disassembly, making them ideal for systems requiring frequent maintenance, but they may exhibit lower pressure ratings compared to welded joints. Welded joints provide superior strength and permanent reliability due to the metallurgical bonding, resulting in higher pressure and temperature tolerance with minimal leakage risk. Industries demanding maximum structural integrity and leak-proof performance, such as petrochemical and high-pressure steam systems, predominantly prefer welded joints.

Maintenance and Repair Considerations

Flanged joints offer easier maintenance and repair due to their bolted design, enabling quick disassembly without specialized equipment, which reduces downtime and lowers labor costs. Welded joints provide a permanent, leak-proof connection but require cutting and re-welding for repairs, demanding skilled labor and extended service interruptions. Your choice depends on the priority of ease of access for maintenance versus the need for a robust, leak-resistant seal.

Cost Analysis: Initial and Long-Term Expenses

Flanged joints typically incur higher initial costs due to the need for additional components such as bolts, gaskets, and flanges, but they offer lower long-term maintenance expenses thanks to easier disassembly and repair. Welded joints present lower upfront material costs since they eliminate extra parts, yet they often lead to increased long-term expenses caused by more complex inspections, potential failure points, and higher repair difficulties. Evaluating cost-effectiveness depends on application requirements, operational conditions, and maintenance strategies, where flanged joints favor reusability and flexibility, while welded joints excel in permanent, leak-proof connections.

Common Applications and Industry Usage

Flanged joints are commonly used in piping systems that require frequent maintenance, disassembly, or inspection, such as in chemical processing, water treatment, and oil refineries. Welded joints provide permanent, leak-proof connections ideal for high-pressure and high-temperature applications in industries like power generation, aerospace, and petrochemical plants. Your choice between flanged and welded joints depends on the need for flexibility, durability, and the specific operational environment of your infrastructure.

Pros and Cons: Flanged Joint vs Welded Joint

Flanged joints offer easy disassembly and maintenance, making them ideal for systems requiring frequent inspection or replacement, but they can be prone to leaks and require more space compared to welded joints. Welded joints provide a strong, permanent, and leak-proof connection suitable for high-pressure and high-temperature applications, though they are difficult to modify and require skilled labor and special equipment. Your choice depends on the specific application requirements, balancing the need for durability and ease of maintenance.

Flanged joint vs welded joint Infographic

libmatt.com

libmatt.com