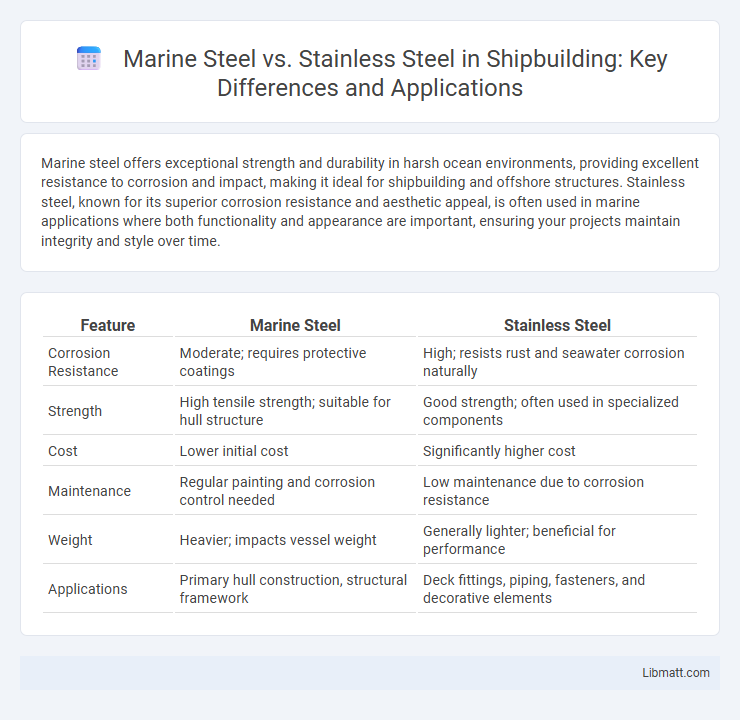

Marine steel offers exceptional strength and durability in harsh ocean environments, providing excellent resistance to corrosion and impact, making it ideal for shipbuilding and offshore structures. Stainless steel, known for its superior corrosion resistance and aesthetic appeal, is often used in marine applications where both functionality and appearance are important, ensuring your projects maintain integrity and style over time.

Table of Comparison

| Feature | Marine Steel | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Moderate; requires protective coatings | High; resists rust and seawater corrosion naturally |

| Strength | High tensile strength; suitable for hull structure | Good strength; often used in specialized components |

| Cost | Lower initial cost | Significantly higher cost |

| Maintenance | Regular painting and corrosion control needed | Low maintenance due to corrosion resistance |

| Weight | Heavier; impacts vessel weight | Generally lighter; beneficial for performance |

| Applications | Primary hull construction, structural framework | Deck fittings, piping, fasteners, and decorative elements |

Introduction to Marine Steel and Stainless Steel

Marine steel offers enhanced corrosion resistance and high tensile strength, making it ideal for harsh ocean environments and structural applications exposed to seawater. Stainless steel contains a high chromium content that provides excellent rust resistance and durability, often used for marine hardware, fasteners, and decorative elements. Understanding your specific project requirements will help determine whether marine steel or stainless steel is the better choice for long-term performance and protection against saltwater corrosion.

Composition Differences Between Marine Steel and Stainless Steel

Marine steel primarily consists of carbon steel with added copper for enhanced corrosion resistance in saltwater environments, whereas stainless steel contains significant amounts of chromium (typically 10.5% or higher) and nickel, forming a passive oxide layer that prevents rust and enhances durability. The chromium content in stainless steel makes it highly resistant to oxidation and staining, while marine steel relies on protective coatings and alloying elements to combat corrosion. These compositional differences determine their suitability for marine applications, with stainless steel offering superior corrosion resistance and marine steel providing cost-effective strength with moderate protection.

Corrosion Resistance: Marine Steel vs Stainless Steel

Marine steel offers enhanced corrosion resistance compared to standard carbon steel due to its protective coatings and alloying elements, making it suitable for harsh saltwater environments. Stainless steel, particularly grades like 316 and 304, exhibits superior corrosion resistance through its high chromium and nickel content, forming a passive oxide layer that prevents rust and pitting. In marine applications, stainless steel outperforms marine steel in long-term durability against corrosion, especially in constantly wet or highly saline conditions.

Strength and Durability Comparison

Marine steel exhibits superior tensile strength and impact resistance compared to stainless steel, making it ideal for heavy-duty maritime applications exposed to harsh physical stresses. Stainless steel offers excellent corrosion resistance, particularly grades like 316, but generally has lower strength under high mechanical loads than marine steel alloys. The choice between marine steel and stainless steel depends on balancing the need for extreme durability against exposure to corrosive saltwater environments.

Common Applications in Marine Environments

Marine steel is commonly used for shipbuilding, offshore platforms, and harbor infrastructure due to its high strength and durability in harsh saltwater conditions. Stainless steel is preferred for marine applications like deck fittings, fasteners, and marine hardware because of its exceptional corrosion resistance and low maintenance requirements. Your choice between the two materials depends on the specific marine environment and the performance demands of the application.

Maintenance and Longevity Considerations

Marine steel requires regular maintenance such as cleaning and protective coatings to prevent rust and corrosion in harsh saltwater environments, while stainless steel offers superior corrosion resistance with minimal upkeep due to its chromium content forming a protective oxide layer. The longevity of marine steel depends heavily on consistent maintenance, whereas stainless steel generally provides longer service life with less frequent intervention. Choosing stainless steel reduces long-term maintenance costs and downtime, making it ideal for critical marine applications exposed to moisture and saline conditions.

Cost Analysis of Marine Steel vs Stainless Steel

Marine steel typically costs less than stainless steel due to its lower alloy content and simpler manufacturing process, making it a more budget-friendly option for large-scale marine constructions. Stainless steel, especially grades like 316 or 304, commands a higher price reflecting its enhanced corrosion resistance, longevity, and reduced maintenance expenses in harsh marine environments. Evaluating the total cost of ownership requires balancing the initial material price against long-term durability and repair costs associated with saltwater exposure.

Environmental Impact and Sustainability

Marine steel offers greater recyclability and lower carbon emissions during production compared to stainless steel, making it a more sustainable choice for large-scale marine infrastructure. Stainless steel, while corrosion-resistant and durable, often requires more energy-intensive alloying elements like nickel and chromium, increasing its environmental footprint. Choosing marine steel can reduce your project's environmental impact through enhanced recyclability and lower resource consumption.

Choosing the Right Steel for Marine Projects

Marine steel offers superior strength and excellent corrosion resistance, making it ideal for heavy-duty marine structures and shipbuilding exposed to harsh saltwater environments. Stainless steel, with its higher chromium content, provides enhanced rust resistance and low maintenance, suitable for decorative or lighter marine applications where aesthetic appeal and longevity matter. Selecting the right steel depends on specific project requirements such as load-bearing capacity, exposure to corrosive elements, and budget constraints.

Summary and Final Recommendations

Marine steel offers exceptional strength and durability for heavy-duty maritime structures but requires regular maintenance to prevent corrosion. Stainless steel provides superior corrosion resistance and longer lifespan in saltwater environments, making it ideal for components exposed to harsh marine conditions. For Your projects demanding low maintenance and enhanced longevity, stainless steel is the recommended choice, while marine steel suits applications prioritizing cost-effectiveness and structural strength.

Marine steel vs stainless steel Infographic

libmatt.com

libmatt.com