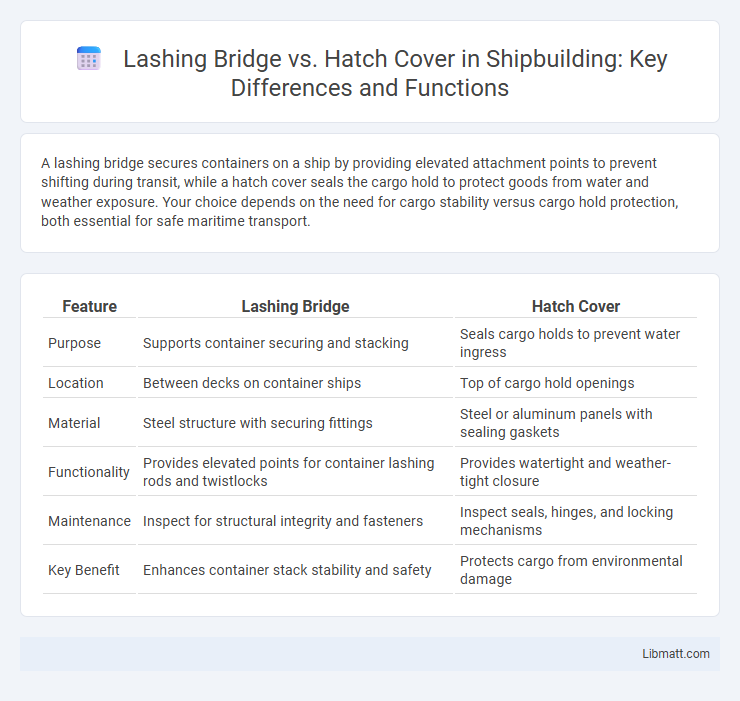

A lashing bridge secures containers on a ship by providing elevated attachment points to prevent shifting during transit, while a hatch cover seals the cargo hold to protect goods from water and weather exposure. Your choice depends on the need for cargo stability versus cargo hold protection, both essential for safe maritime transport.

Table of Comparison

| Feature | Lashing Bridge | Hatch Cover |

|---|---|---|

| Purpose | Supports container securing and stacking | Seals cargo holds to prevent water ingress |

| Location | Between decks on container ships | Top of cargo hold openings |

| Material | Steel structure with securing fittings | Steel or aluminum panels with sealing gaskets |

| Functionality | Provides elevated points for container lashing rods and twistlocks | Provides watertight and weather-tight closure |

| Maintenance | Inspect for structural integrity and fasteners | Inspect seals, hinges, and locking mechanisms |

| Key Benefit | Enhances container stack stability and safety | Protects cargo from environmental damage |

Introduction to Lashing Bridges and Hatch Covers

Lashing bridges are structural frameworks installed on container ships to secure containers and prevent movement during transit, ensuring cargo safety. Hatch covers are protective panels that seal the ship's cargo holds, preventing water ingress and safeguarding the cargo from environmental elements. Both components play crucial roles in maritime shipping by enhancing cargo security and vessel integrity.

Key Functions of Lashing Bridges

Lashing bridges serve the key function of providing elevated structural support for securing containers on container ships, ensuring stability and safety during transit by allowing lashing rods and twist locks to be fastened effectively. Unlike hatch covers, which primarily seal cargo holds to protect against water ingress, lashing bridges focus on maintaining the vertical and horizontal positioning of stacked containers under dynamic sea conditions. Your understanding of these differences is crucial for optimizing container ship operations and ensuring cargo safety.

Primary Role of Hatch Covers

Hatch covers primarily serve to protect cargo holds from water ingress, ensuring the safety and integrity of the goods during maritime transportation. Their tight sealing capabilities prevent seawater, rain, and other external elements from damaging the stored cargo. Unlike lashing bridges, which provide structural support for securing containerized cargo on deck, hatch covers focus on maintaining a dry and secure environment inside the ship's holds.

Structural Differences Between Lashing Bridges and Hatch Covers

Lashing bridges are elevated steel structures installed above ship decks to provide secure attachment points for container lashing, enhancing cargo stability during transit. Hatch covers are robust, watertight panels designed to seal cargo holds, preventing water ingress and protecting the ship's contents from harsh marine environments. Understanding these structural differences helps you ensure proper cargo securing methods and vessel safety compliance.

Impact on Cargo Security: Lashing Bridge vs Hatch Cover

The lashing bridge provides superior cargo security by offering elevated attachment points for securing containers, reducing movement during transit and enhancing overall stability. Hatch covers primarily protect cargo from environmental elements like water and debris but do not contribute directly to securing cargo against shifting. Your choice between lashing bridges and hatch covers impacts how effectively cargo remains stable and protected throughout the voyage.

Influence on Vessel Efficiency and Operations

Lashing bridges enhance vessel efficiency by providing secure and accessible tie-down points, reducing cargo shifts and minimizing handling time during loading and unloading. Hatch covers play a crucial role in protecting cargo from weather and sea conditions, ensuring safe transit and reducing damage-related delays. Your vessel's operational performance depends on the optimal integration of both lashing bridges and hatch covers to balance cargo security with quick turnaround times.

Maintenance Requirements: Lashing Bridge vs Hatch Cover

Lashing bridges require regular inspection and maintenance of structural components, such as securing bolts and welding joints, to ensure stability during cargo securing operations. Hatch covers demand frequent checks for rubber seals and hydraulic systems to maintain watertight integrity and prevent corrosion or leakage. Both structures necessitate preventive upkeep, but hatch covers often involve more complex sealing system maintenance compared to the primarily structural focus of lashing bridges.

Safety Considerations for Each Structure

Lashing bridges provide elevated securing points for cargo, reducing the risk of shifting during transit and enhancing overall ship stability, which is critical for your vessel's safety. Hatch covers, designed to protect cargo holds from water ingress, must be regularly inspected to maintain watertight integrity and prevent structural failures that could lead to cargo damage or accidents. Proper maintenance and adherence to safety protocols for both lashing bridges and hatch covers are essential to ensure secure cargo transport and protect crew welfare.

Cost Implications and Investment Analysis

Lashing bridges generally require higher initial investment due to their complex structural design and materials, impacting overall capital expenditure for shipping vessels. Hatch covers involve relatively lower upfront costs but may lead to increased maintenance expenses over time due to frequent exposure and mechanical wear. You should evaluate lifecycle costs and operational efficiency to determine which option aligns best with your long-term budget and vessel functionality requirements.

Choosing Between Lashing Bridge and Hatch Cover: Key Factors

Choosing between a lashing bridge and a hatch cover depends primarily on cargo type, weather protection needs, and structural requirements. Lashing bridges provide elevated securing points ideal for stacked containers and heavy cargo, enhancing stability during transit but offering minimal protection from elements. In contrast, hatch covers ensure watertight sealing for bulk goods while facilitating easier access but lack robust cargo lashing capabilities.

Lashing bridge vs hatch cover Infographic

libmatt.com

libmatt.com