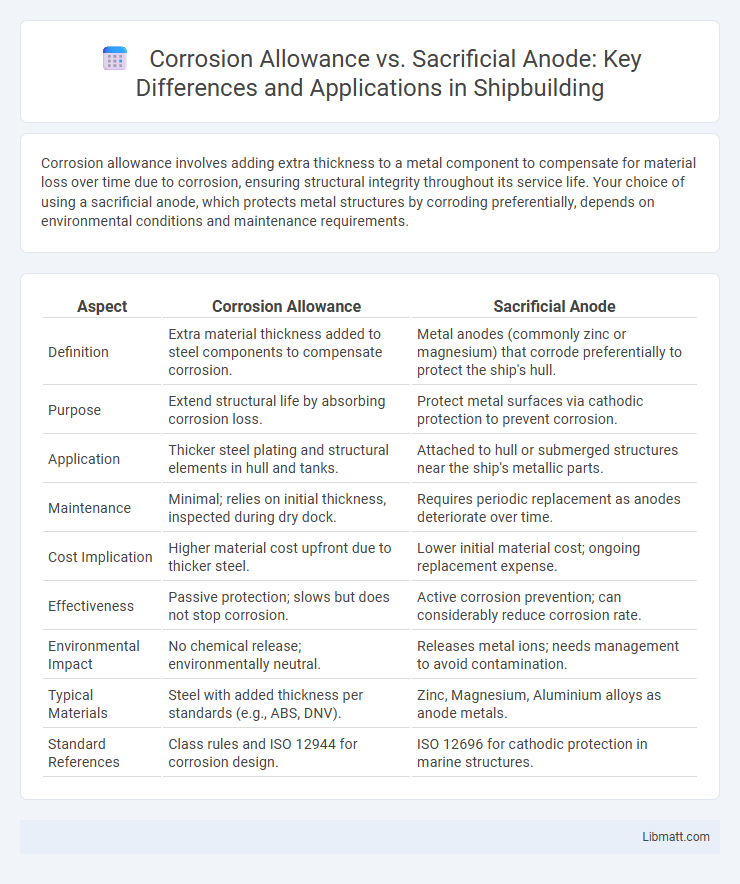

Corrosion allowance involves adding extra thickness to a metal component to compensate for material loss over time due to corrosion, ensuring structural integrity throughout its service life. Your choice of using a sacrificial anode, which protects metal structures by corroding preferentially, depends on environmental conditions and maintenance requirements.

Table of Comparison

| Aspect | Corrosion Allowance | Sacrificial Anode |

|---|---|---|

| Definition | Extra material thickness added to steel components to compensate corrosion. | Metal anodes (commonly zinc or magnesium) that corrode preferentially to protect the ship's hull. |

| Purpose | Extend structural life by absorbing corrosion loss. | Protect metal surfaces via cathodic protection to prevent corrosion. |

| Application | Thicker steel plating and structural elements in hull and tanks. | Attached to hull or submerged structures near the ship's metallic parts. |

| Maintenance | Minimal; relies on initial thickness, inspected during dry dock. | Requires periodic replacement as anodes deteriorate over time. |

| Cost Implication | Higher material cost upfront due to thicker steel. | Lower initial material cost; ongoing replacement expense. |

| Effectiveness | Passive protection; slows but does not stop corrosion. | Active corrosion prevention; can considerably reduce corrosion rate. |

| Environmental Impact | No chemical release; environmentally neutral. | Releases metal ions; needs management to avoid contamination. |

| Typical Materials | Steel with added thickness per standards (e.g., ABS, DNV). | Zinc, Magnesium, Aluminium alloys as anode metals. |

| Standard References | Class rules and ISO 12944 for corrosion design. | ISO 12696 for cathodic protection in marine structures. |

Introduction to Corrosion Protection Strategies

Corrosion allowance involves designing structures with extra material thickness to compensate for inevitable corrosion loss over time, ensuring durability and safety. Sacrificial anodes work by providing a more reactive metal that preferentially corrodes, protecting your main metal structure from damage. Both strategies are critical in corrosion protection, with corrosion allowance focusing on passive defense and sacrificial anodes offering active electrochemical protection.

Understanding Corrosion Allowance

Corrosion allowance refers to the intentional extra thickness added to metal structures to compensate for expected material loss due to corrosion over time. This method extends the lifespan of equipment by sacrificing the added material rather than altering the chemical environment. Unlike sacrificial anodes that protect metals electrochemically, corrosion allowance relies solely on physical thickness increases to prevent structural failure.

Principles of Sacrificial Anode Protection

Sacrificial anode protection operates on the principle of galvanic corrosion, where a more reactive metal anode corrodes preferentially, protecting the primary metal structure. This method contrasts with corrosion allowance, which involves designing thicker materials to withstand corrosion over time without active protection. Sacrificial anodes provide continuous electrochemical protection by polarizing the metal surface, minimizing metal loss and extending the lifespan of pipelines, tanks, and marine structures.

Key Differences Between Corrosion Allowance and Sacrificial Anodes

Corrosion allowance involves adding extra material thickness to a structure to compensate for expected metal loss over time, ensuring durability and extended service life. Sacrificial anodes are metals with a higher electrochemical potential that corrode preferentially, protecting the primary metal by acting as a controlled source of corrosion. Your choice between these methods depends on factors like environmental conditions, maintenance capabilities, and cost-effectiveness for long-term corrosion protection.

Advantages of Corrosion Allowance

Corrosion allowance offers the advantage of a straightforward design approach by incorporating extra material thickness to compensate for expected metal loss, ensuring structural integrity over time without requiring active maintenance. This method provides long-term reliability in harsh environments with minimal intervention, making it suitable for critical infrastructure where consistent protection is essential. Your choice of corrosion allowance simplifies inspection procedures and reduces dependence on external components like sacrificial anodes that may degrade or require replacement.

Benefits of Sacrificial Anode Systems

Sacrificial anode systems provide effective corrosion protection by actively preventing metal surfaces from deteriorating, extending the lifespan of steel structures in marine and underground environments. These systems offer low maintenance requirements and continuous corrosion control without the need for extensive coatings or frequent inspections. The self-regulating nature of sacrificial anodes ensures cost-effective protection by sacrificing the anode material instead of the protected metal, reducing overall repair and replacement expenses.

Limitations of Corrosion Allowance Methods

Corrosion allowance methods are limited by the unpredictability of corrosion rates, which can lead to either insufficient protection or excessive material use, increasing costs. This approach does not actively prevent corrosion but relies on additional material thickness, making it less effective for complex or aggressive environments. Sacrificial anodes offer targeted protection by preferentially corroding, reducing the risk of structural damage that corrosion allowance alone cannot adequately address.

Drawbacks of Sacrificial Anode Protection

Sacrificial anode protection can lead to frequent maintenance due to the gradual consumption of anodes, requiring regular replacement to maintain effective corrosion control. Its effectiveness is limited in large or complex structures where uneven current distribution may cause localized corrosion. Additionally, the sacrificial anode method may introduce hydrogen embrittlement in certain metals, compromising structural integrity over time.

Application Scenarios: When to Use Each Method

Corrosion allowance is ideal for structures exposed to uniform corrosion in harsh environments, such as pipelines and storage tanks, where extra material thickness ensures long-term durability. Sacrificial anodes are best suited for underground or underwater metal structures, like ships and buried pipelines, providing cathodic protection by corroding preferentially. You should select corrosion allowance for predictable wear and sacrificial anodes for active electrochemical protection in moist or submerged conditions.

Selecting the Optimal Corrosion Protection Approach

Selecting the optimal corrosion protection approach requires evaluating environmental conditions, material compatibility, and maintenance capabilities. Corrosion allowance involves designing extra material thickness to endure gradual metal loss, ideal for predictable and uniform corrosion environments. In contrast, sacrificial anodes offer efficient protection in highly corrosive or submerged conditions by actively preventing metal deterioration through galvanic action.

Corrosion allowance vs sacrificial anode Infographic

libmatt.com

libmatt.com