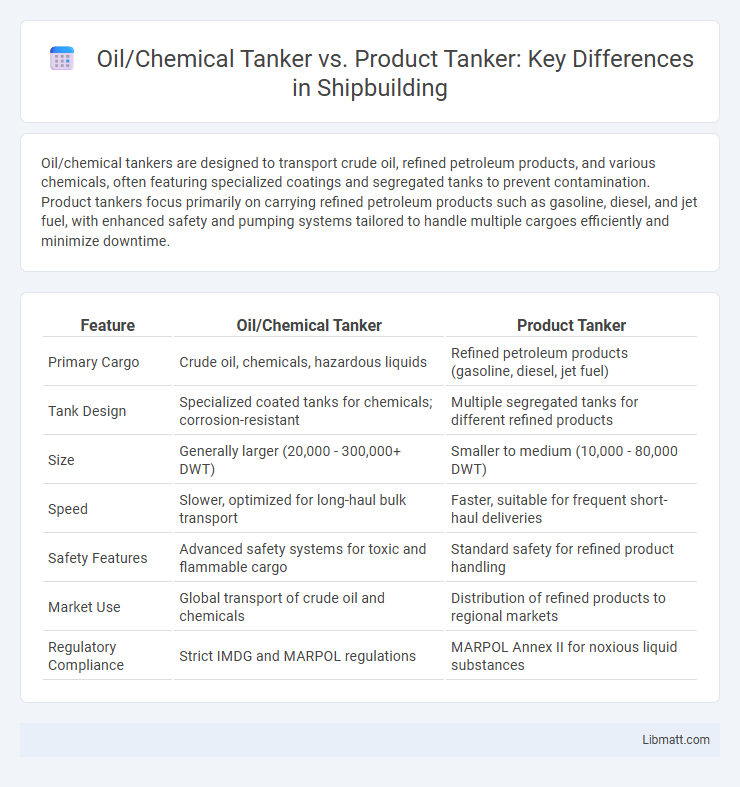

Oil/chemical tankers are designed to transport crude oil, refined petroleum products, and various chemicals, often featuring specialized coatings and segregated tanks to prevent contamination. Product tankers focus primarily on carrying refined petroleum products such as gasoline, diesel, and jet fuel, with enhanced safety and pumping systems tailored to handle multiple cargoes efficiently and minimize downtime.

Table of Comparison

| Feature | Oil/Chemical Tanker | Product Tanker |

|---|---|---|

| Primary Cargo | Crude oil, chemicals, hazardous liquids | Refined petroleum products (gasoline, diesel, jet fuel) |

| Tank Design | Specialized coated tanks for chemicals; corrosion-resistant | Multiple segregated tanks for different refined products |

| Size | Generally larger (20,000 - 300,000+ DWT) | Smaller to medium (10,000 - 80,000 DWT) |

| Speed | Slower, optimized for long-haul bulk transport | Faster, suitable for frequent short-haul deliveries |

| Safety Features | Advanced safety systems for toxic and flammable cargo | Standard safety for refined product handling |

| Market Use | Global transport of crude oil and chemicals | Distribution of refined products to regional markets |

| Regulatory Compliance | Strict IMDG and MARPOL regulations | MARPOL Annex II for noxious liquid substances |

Overview: Oil/Chemical Tankers vs Product Tankers

Oil/chemical tankers are specialized vessels designed to transport a variety of liquid chemicals and petroleum products, equipped with sophisticated coatings and segregation systems to prevent contamination. Product tankers primarily carry refined petroleum products such as gasoline, diesel, and jet fuel, focusing on efficient loading and unloading with multiple segregated cargo tanks. Both types emphasize safety and environmental protection but differ in cargo versatility and construction specifications tailored to their specific liquid cargoes.

Key Differences in Design and Structure

Oil/chemical tankers feature segregated cargo tanks with specialized coatings or stainless steel to handle corrosive or hazardous chemicals, ensuring safe transport of aggressive substances. Product tankers have multiple smaller tanks designed for carrying refined petroleum products, often equipped with heating coils to maintain product quality during transit. Structural differences include thicker hulls and reinforced bulkheads in chemical tankers for enhanced safety and containment compared to the simpler design of product tankers optimized for frequent cargo switching.

Types of Cargo Carried

Oil/chemical tankers primarily transport crude oil, refined petroleum products, and hazardous chemicals, requiring specialized coatings and compartmentalization to prevent contamination. Product tankers mainly carry refined petroleum products like gasoline, diesel, jet fuel, and lubricants, designed for safe transfer and storage of lighter, purified cargoes. Your choice between these vessels depends on the specific cargo's chemical properties and handling requirements.

Cargo Handling Systems Comparison

Oil/chemical tankers utilize complex cargo handling systems equipped with advanced pumps, multiple segregated tanks, and extensive safety features to transport hazardous chemicals and crude oil efficiently. Product tankers feature more versatile cargo systems designed for refined petroleum products, incorporating flexible piping arrangements and precise temperature control to maintain product quality during transit. Both tanker types employ inert gas systems and vapor recovery units, but oil/chemical tankers emphasize corrosion-resistant materials due to aggressive cargoes.

Safety Features and Environmental Concerns

Oil/chemical tankers incorporate advanced inert gas systems and double hull constructions to prevent spills and reduce fire hazards, ensuring the safe transport of hazardous liquids. Product tankers emphasize segregated cargo tanks and vapor recovery units to minimize cross-contamination and air pollution during loading and unloading processes. Both vessel types adhere to MARPOL regulations and utilize ballast water management systems to mitigate environmental impact on marine ecosystems.

Regulatory Framework and Classification

Oil/chemical tankers and product tankers are governed by strict regulatory frameworks such as the International Maritime Organization's (IMO) International Convention for the Prevention of Pollution from Ships (MARPOL) Annex I, with oil/chemical tankers subject to more stringent requirements due to their hazardous cargo. Classification societies like ABS, DNV, and Lloyd's Register impose tailored standards on ship construction, equipment, and operation, ensuring compliance with safety and environmental regulations specific to each tanker type. Your choice between these vessels should consider the regulatory complexities and classification criteria impacting operational efficiency and risk management.

Operational Flexibility and Efficiency

Oil/chemical tankers offer greater operational flexibility by accommodating a wide range of liquid cargoes, including crude oil, chemicals, and refined products, supported by specialized tank coatings and segregation systems. Product tankers, designed primarily for refined petroleum products, provide enhanced efficiency in frequent port calls and shorter voyages due to their smaller size and optimized cargo handling systems. Your choice between these vessels should consider the trade-off between the versatility of oil/chemical tankers and the cost-effectiveness of product tankers in servicing specific market demands.

Typical Trade Routes and Markets

Oil/chemical tankers predominantly operate on long-haul trade routes connecting major crude oil producing regions like the Middle East, West Africa, and Latin America with refining hubs in Asia, Europe, and North America. Product tankers typically serve shorter, regional routes, facilitating distribution between coastal refineries and consumption centers in markets such as the U.S. Gulf Coast, Northwest Europe, and Southeast Asia. Understanding these distinct trade patterns helps optimize your fleet deployment strategies for market demands and cargo types.

Cost Implications and Economics

Oil/chemical tankers typically incur higher operational costs due to specialized safety equipment and stringent regulatory compliance, impacting overall economics. Product tankers, designed for refined products, often benefit from more flexible routing and quicker turnaround, enhancing cost efficiency. Your choice between the two influences fuel consumption, maintenance expenses, and cargo handling complexity, directly affecting profitability.

Future Trends in Tanker Shipping

The future trends in oil/chemical tanker and product tanker shipping emphasize increased adoption of eco-friendly technologies, including LNG propulsion and advanced ballast water treatment systems to meet stringent environmental regulations. Digitalization and automation are projected to enhance operational efficiency, with predictive maintenance and real-time monitoring minimizing downtime and fuel consumption. Market demand shifts toward specialized vessels with improved safety features and flexible cargo handling capabilities to accommodate diverse chemical and refined petroleum products.

Oil/chemical tanker vs product tanker Infographic

libmatt.com

libmatt.com