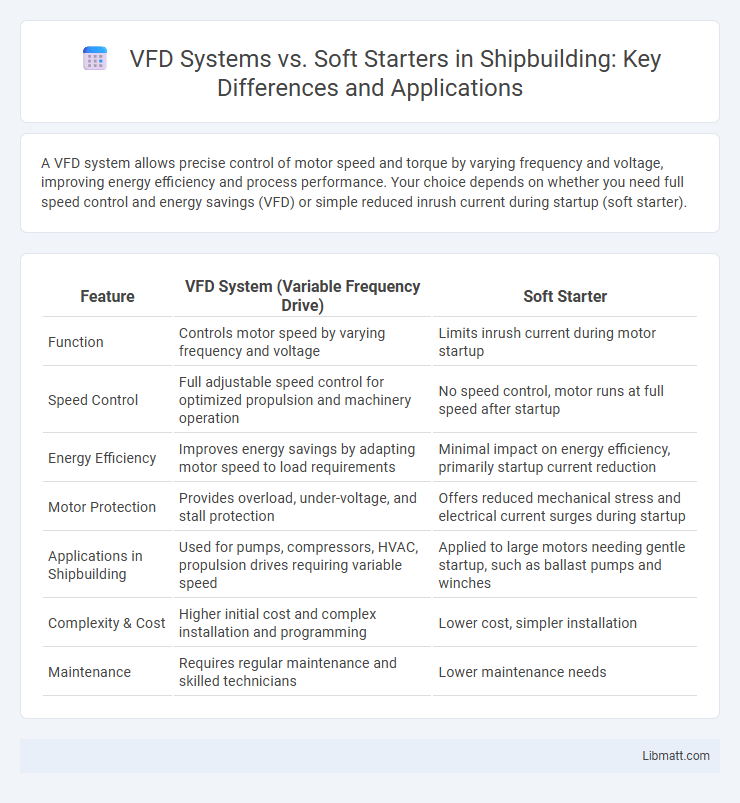

A VFD system allows precise control of motor speed and torque by varying frequency and voltage, improving energy efficiency and process performance. Your choice depends on whether you need full speed control and energy savings (VFD) or simple reduced inrush current during startup (soft starter).

Table of Comparison

| Feature | VFD System (Variable Frequency Drive) | Soft Starter |

|---|---|---|

| Function | Controls motor speed by varying frequency and voltage | Limits inrush current during motor startup |

| Speed Control | Full adjustable speed control for optimized propulsion and machinery operation | No speed control, motor runs at full speed after startup |

| Energy Efficiency | Improves energy savings by adapting motor speed to load requirements | Minimal impact on energy efficiency, primarily startup current reduction |

| Motor Protection | Provides overload, under-voltage, and stall protection | Offers reduced mechanical stress and electrical current surges during startup |

| Applications in Shipbuilding | Used for pumps, compressors, HVAC, propulsion drives requiring variable speed | Applied to large motors needing gentle startup, such as ballast pumps and winches |

| Complexity & Cost | Higher initial cost and complex installation and programming | Lower cost, simpler installation |

| Maintenance | Requires regular maintenance and skilled technicians | Lower maintenance needs |

Introduction to VFD Systems and Soft Starters

Variable Frequency Drives (VFD) systems regulate motor speed by varying the frequency and voltage supplied, offering precise control and energy savings. Soft starters gradually increase motor voltage to reduce inrush current and mechanical stress during startup, enhancing equipment longevity. Your choice between a VFD and soft starter depends on the required motor control complexity and application efficiency.

Basic Principles: How VFDs Work

Variable Frequency Drives (VFDs) control motor speed by adjusting the frequency and voltage supplied to the electric motor, enabling precise speed regulation and energy efficiency. Unlike soft starters, which only limit the inrush current during motor startup by gradually increasing voltage, VFDs provide continuous speed control throughout operation. Understanding these basic principles helps you optimize motor performance and energy savings in your industrial applications.

Basic Principles: How Soft Starters Work

Soft starters control the motor's initial voltage by gradually increasing it, reducing inrush current and mechanical stress during startup. These devices use thyristors to modulate power delivery, ensuring a smooth acceleration without continuous speed control. Your equipment benefits from decreased wear and improved lifespan compared to direct-on-line starters.

Key Differences Between VFD Systems and Soft Starters

VFD systems control motor speed and torque by varying voltage and frequency, enabling precise motor performance and energy savings, while soft starters primarily limit inrush current during motor startup to reduce mechanical stress without speed control. VFDs offer continuous speed adjustment and are ideal for variable load applications, whereas soft starters are simpler devices designed solely for smooth starting and stopping. Your choice depends on whether you need efficient speed regulation or just a gentle motor startup method.

Energy Efficiency Comparison

Variable Frequency Drives (VFDs) offer superior energy efficiency compared to soft starters by providing precise motor speed control, reducing energy consumption under variable load conditions. Soft starters primarily manage voltage ramp-up during motor startup without optimizing speed or torque during operation, leading to higher energy usage in continuous processes. Studies indicate VFDs can achieve energy savings of up to 30% in applications with fluctuating loads, whereas soft starters mainly contribute to mechanical stress reduction rather than significant energy reduction.

Application Suitability: When to Use VFDs vs Soft Starters

VFD systems are ideal for applications requiring precise motor speed control and energy efficiency, such as conveyor belts and pumps operating under variable load conditions. Soft starters are best suited for simple starting and stopping of motors with reduced inrush current, commonly used in fans, compressors, and high inertia loads where speed variation is not necessary. Selection depends on the need for speed regulation, torque control, and operational flexibility in the specific industrial process.

Impact on Motor Life and Performance

Variable Frequency Drives (VFDs) enhance motor life by providing precise speed control and smooth acceleration, reducing mechanical stress and electrical wear. Soft starters limit inrush current during startup, minimizing initial torque spikes but lack continuous speed regulation, which can lead to higher operational strain. VFDs improve motor performance by allowing variable speed operation, optimizing energy efficiency and process control, whereas soft starters primarily focus on easing startup without ongoing performance benefits.

Cost Analysis: Initial Investment and Long-Term Savings

VFD systems typically demand a higher initial investment compared to soft starters due to their advanced electronic components and control capabilities. However, VFDs provide significant long-term savings through energy efficiency, reduced mechanical wear, and lower maintenance costs in variable load applications. Soft starters offer lower upfront costs but lack the energy-saving benefits of VFDs, making them more suitable for applications with simple starting requirements and constant speed operations.

Installation and Maintenance Requirements

VFD systems require more complex installation involving precise wiring, programmable interfaces, and often additional cooling components compared to soft starters, which have simpler connection and setup processes. Maintenance of VFDs demands routine monitoring of electronic components, firmware updates, and potential troubleshooting of complex control algorithms, while soft starters primarily require inspection for mechanical wear and basic electrical checks. The higher upfront complexity and ongoing maintenance of VFDs are balanced by enhanced control capabilities and energy savings, whereas soft starters offer easier installation and lower maintenance costs with limited functionality.

Conclusion: Choosing the Right Solution for Your Application

Choosing between a VFD system and a soft starter depends on your application's specific needs for motor control, energy efficiency, and start-stop frequency. VFDs provide precise speed regulation and significant energy savings in variable load conditions, while soft starters offer simple, cost-effective solutions for reducing inrush current and mechanical stress during motor startup. Your decision should align with operational requirements, budget constraints, and desired control complexity to optimize performance and longevity.

VFD system vs soft starter Infographic

libmatt.com

libmatt.com