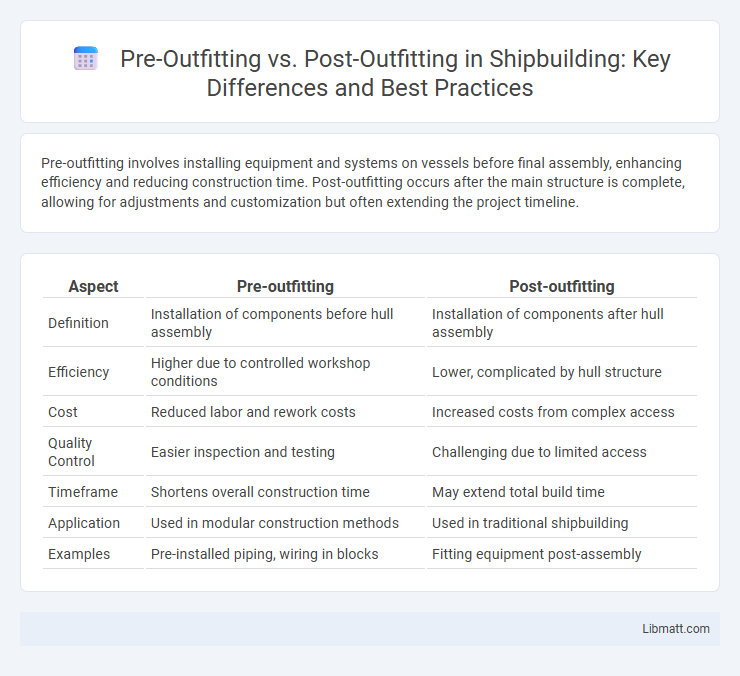

Pre-outfitting involves installing equipment and systems on vessels before final assembly, enhancing efficiency and reducing construction time. Post-outfitting occurs after the main structure is complete, allowing for adjustments and customization but often extending the project timeline.

Table of Comparison

| Aspect | Pre-outfitting | Post-outfitting |

|---|---|---|

| Definition | Installation of components before hull assembly | Installation of components after hull assembly |

| Efficiency | Higher due to controlled workshop conditions | Lower, complicated by hull structure |

| Cost | Reduced labor and rework costs | Increased costs from complex access |

| Quality Control | Easier inspection and testing | Challenging due to limited access |

| Timeframe | Shortens overall construction time | May extend total build time |

| Application | Used in modular construction methods | Used in traditional shipbuilding |

| Examples | Pre-installed piping, wiring in blocks | Fitting equipment post-assembly |

Introduction to Outfitting Processes

Pre-outfitting involves assembling and installing components and systems within ship sections before final construction, significantly enhancing efficiency and reducing overall build time. Post-outfitting occurs after the hull assembly, requiring on-site installation of equipment, which can complicate access and extend project duration. Understanding these outfitting processes helps you optimize workflow and manage resources effectively in shipbuilding projects.

Defining Pre-outfitting

Pre-outfitting refers to the process of installing equipment, systems, or components into a structure or vessel during the initial construction phase, enhancing efficiency and reducing time spent on-site. This method allows for precise quality control and streamlined assembly by integrating parts in controlled environments such as factories or shipyards. Pre-outfitting contrasts with post-outfitting, which involves fitting out after the main structure is completed, often leading to longer project timelines and increased logistical challenges.

Defining Post-outfitting

Post-outfitting refers to the process of installing equipment, fixtures, and systems after the primary construction phase of a building or vessel is completed. This method allows for customization and flexibility, enabling modifications based on final design requirements or client preferences. Post-outfitting is commonly used in shipbuilding and commercial construction to ensure that specialized components are integrated efficiently without disrupting the initial structural work.

Key Differences Between Pre- and Post-outfitting

Pre-outfitting involves assembling components and systems at the manufacturing facility before installation, ensuring higher quality control and reducing on-site labor costs. Post-outfitting occurs after the primary structure is built, allowing for greater flexibility to customize Your project based on real-time requirements but often resulting in longer project timelines. The key differences lie in timing, cost efficiency, quality assurance, and adaptability to design changes during construction.

Advantages of Pre-outfitting

Pre-outfitting offers significant advantages by enabling faster on-site assembly, reducing labor costs, and minimizing project delays through streamlined workflow coordination. This method improves quality control as components are pre-assembled under controlled factory conditions, enhancing precision and reducing errors. Early integration of systems also facilitates better planning and reduces material waste, contributing to overall project efficiency and cost savings.

Benefits of Post-outfitting

Post-outfitting offers flexibility by allowing customization to suit evolving project requirements, minimizing initial capital expenditure and storage needs. It enables on-site adjustments, improving accuracy and reducing rework risks, which enhances overall construction efficiency. Your project benefits from streamlined timelines as equipment and components are installed only when needed, optimizing workforce deployment.

Challenges and Limitations of Each Method

Pre-outfitting faces challenges such as limited flexibility for design changes and complex logistics due to the need for precise planning and coordination before installation. Post-outfitting can encounter limitations including increased on-site labor costs, potential scheduling delays, and difficulties in integration with existing structures or systems. Both methods require careful management to address spatial constraints and ensure quality control throughout the construction process.

Cost Implications: Pre-outfitting vs Post-outfitting

Pre-outfitting typically reduces overall project costs by allowing bulk purchasing and streamlined labor scheduling, while post-outfitting often incurs higher expenses due to onsite modifications and potential delays. You can optimize budget allocation by choosing pre-outfitting, as it minimizes rework and improves efficiency during construction. Cost implications between these methods hinge on project timing, labor rates, and material availability.

Industry Applications and Case Studies

Pre-outfitting enhances efficiency in shipbuilding and construction industries by allowing critical systems installation before main assembly, reducing on-site labor and timeline. Case studies in aerospace demonstrate pre-outfitting's role in error reduction and improved quality control by integrating complex wiring and piping beforehand. Your project can benefit from post-outfitting when customization or late-stage adjustments are essential, as seen in oil and gas platforms where equipment addition after structural completion is common.

Future Trends in Outfitting Techniques

Future trends in outfitting techniques emphasize increased use of pre-outfitting to enhance efficiency, reduce on-site labor costs, and minimize construction delays. Advanced modular components and digital twin technology allow precise integration and customization before installation, improving overall project quality and sustainability. Your ability to leverage these innovations will drive competitive advantage in fast-evolving architectural and industrial sectors.

Pre-outfitting vs post-outfitting Infographic

libmatt.com

libmatt.com