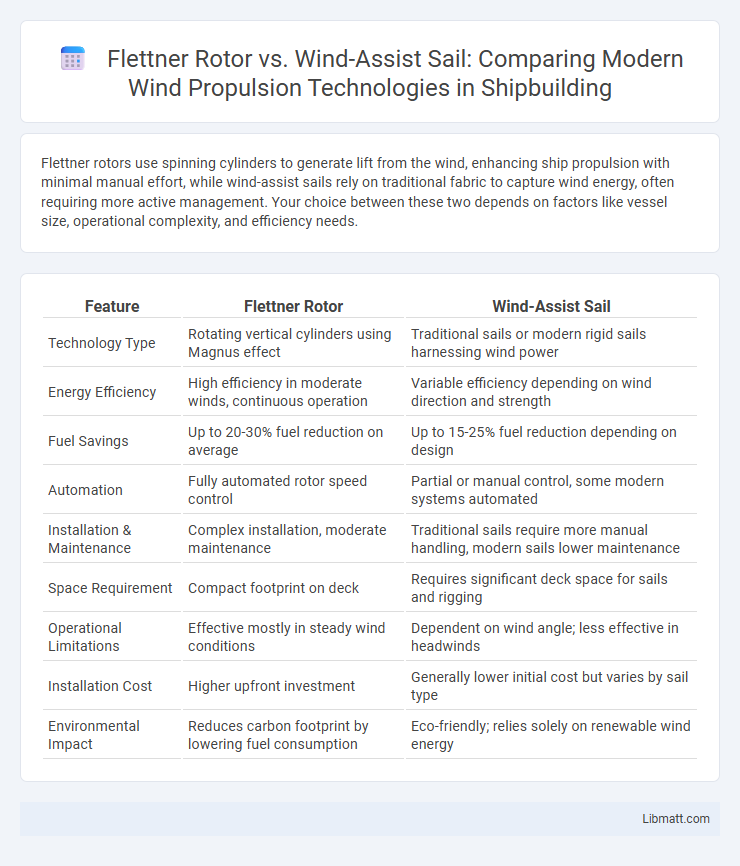

Flettner rotors use spinning cylinders to generate lift from the wind, enhancing ship propulsion with minimal manual effort, while wind-assist sails rely on traditional fabric to capture wind energy, often requiring more active management. Your choice between these two depends on factors like vessel size, operational complexity, and efficiency needs.

Table of Comparison

| Feature | Flettner Rotor | Wind-Assist Sail |

|---|---|---|

| Technology Type | Rotating vertical cylinders using Magnus effect | Traditional sails or modern rigid sails harnessing wind power |

| Energy Efficiency | High efficiency in moderate winds, continuous operation | Variable efficiency depending on wind direction and strength |

| Fuel Savings | Up to 20-30% fuel reduction on average | Up to 15-25% fuel reduction depending on design |

| Automation | Fully automated rotor speed control | Partial or manual control, some modern systems automated |

| Installation & Maintenance | Complex installation, moderate maintenance | Traditional sails require more manual handling, modern sails lower maintenance |

| Space Requirement | Compact footprint on deck | Requires significant deck space for sails and rigging |

| Operational Limitations | Effective mostly in steady wind conditions | Dependent on wind angle; less effective in headwinds |

| Installation Cost | Higher upfront investment | Generally lower initial cost but varies by sail type |

| Environmental Impact | Reduces carbon footprint by lowering fuel consumption | Eco-friendly; relies solely on renewable wind energy |

Introduction to Wind-Assisted Propulsion Technologies

Wind-assisted propulsion technologies use renewable wind energy to reduce fuel consumption and emissions in maritime transport. Flettner rotors harness the Magnus effect through rotating cylindrical sails, generating thrust from wind forces, while traditional wind-assist sails rely on aerodynamic lift created by fixed or adjustable fabric surfaces. Both approaches contribute to energy-efficient shipping, but Flettner rotors offer automated operation and variable thrust control compared to manually managed wind-assist sails.

Overview of Flettner Rotor Systems

Flettner rotor systems utilize spinning cylindrical rotors to harness the Magnus effect, converting wind energy into thrust for vessel propulsion. These rotors, typically powered by electric motors, can significantly reduce fuel consumption and emissions when integrated with conventional ship engines. The technology provides a controlled, efficient, and scalable wind-assist solution compared to traditional wind-assist sails, which rely solely on aerodynamic lift forces.

Fundamentals of Wind-Assist Sail Technology

Wind-assist sail technology harnesses aerodynamic principles to improve vessel propulsion efficiency by converting wind energy into forward thrust. Flettner rotors utilize the Magnus effect, where spinning cylinders generate lift perpendicular to wind direction, enhancing fuel savings and reducing emissions. Your choice between traditional wind-assist sails and Flettner rotors depends on factors like vessel size, operational routes, and desired fuel efficiency gains.

Key Operational Differences

Flettner rotors use spinning cylinders to generate lift through the Magnus effect, providing consistent propulsion regardless of wind direction, while wind-assist sails rely on traditional aerodynamic lift by capturing wind directly. The mechanical nature of Flettner rotors requires electrical or mechanical power to maintain rotation, making them more controllable in variable wind conditions compared to passive sails. Understanding these operational differences can help you select the most efficient wind-assist technology for your vessel's specific navigation requirements.

Efficiency and Performance Comparison

Flettner rotors generate propulsion by exploiting the Magnus effect, offering higher efficiency in varied wind conditions compared to traditional wind-assist sails, which rely solely on aerodynamic lift. Wind-assist sails perform optimally with steady wind and require specific angles to maximize thrust, whereas Flettner rotors maintain consistent performance and can be mechanically adjusted for directional control. Your vessel's energy savings and speed gains are typically greater with Flettner rotors due to their ability to harness wind power more effectively across a wider range of operating scenarios.

Installation and Integration Challenges

Flettner rotors require complex installation involving heavy mechanical components and precise alignment to ensure efficient operation, often demanding structural reinforcement on existing vessels. Wind-assist sails generally offer simpler integration with flexible rigging options but may face limitations related to mast height and deck space availability. Both systems must carefully address weight distribution and stability impacts to maintain vessel safety and operational efficiency during retrofitting.

Maintenance and Lifecycle Costs

Flettner rotors require regular mechanical maintenance due to their rotating components and electrical systems, leading to moderate lifecycle costs influenced by wear and component replacement. Wind-assist sails, composed of flexible fabric and simpler rigging, generally involve lower maintenance expenses but may experience higher replacement frequency due to weather-related wear and UV damage. Lifecycle costs for wind-assist sails tend to be more variable depending on sail material quality and exposure conditions, while Flettner rotors provide more consistent performance with predictable servicing schedules.

Environmental Impact Assessment

Flettner rotors significantly reduce carbon emissions by harnessing wind power through spinning cylinders that create lift, enhancing fuel efficiency on ships by up to 20%. Wind-assist sails similarly lower greenhouse gas emissions by supplementing engine power but may require more complex adjustments and space constraints on modern vessels. Environmental Impact Assessments indicate Flettner rotors have a smaller ecological footprint due to lower material usage and maintenance demands compared to traditional sails, promoting sustainable maritime transport.

Suitability for Different Vessel Types

Flettner rotors are highly suitable for large commercial vessels such as bulk carriers and container ships due to their automated operation and minimal manual intervention, optimizing fuel efficiency on long ocean routes. Wind-assist sails, including traditional and modern rigid sails, are better suited for smaller vessels or those with varied routes, offering flexibility and lower installation costs. Your choice between the two depends on vessel size, route consistency, and operational preferences.

Future Trends in Maritime Wind Propulsion

Flettner rotors demonstrate significant potential in future maritime wind propulsion by leveraging rotary sails to maximize lift and minimize energy consumption, showing higher efficiency in variable wind conditions compared to traditional wind-assist sails. Advances in automation and lightweight composite materials are driving widespread adoption of Flettner rotors on commercial vessels, offering substantial fuel savings and emissions reduction aligned with IMO 2050 targets. Emerging hybrid systems integrating Flettner rotors with conventional sails and auxiliary propulsion technologies illustrate a trend toward optimized, scalable wind-assisted solutions for sustainable shipping.

Flettner rotor vs wind-assist sail Infographic

libmatt.com

libmatt.com