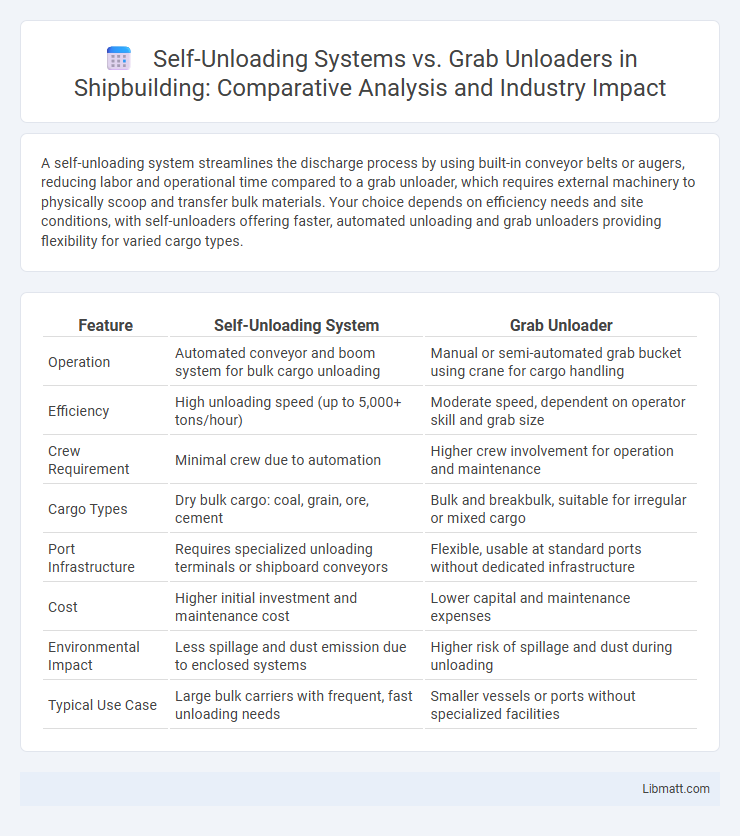

A self-unloading system streamlines the discharge process by using built-in conveyor belts or augers, reducing labor and operational time compared to a grab unloader, which requires external machinery to physically scoop and transfer bulk materials. Your choice depends on efficiency needs and site conditions, with self-unloaders offering faster, automated unloading and grab unloaders providing flexibility for varied cargo types.

Table of Comparison

| Feature | Self-Unloading System | Grab Unloader |

|---|---|---|

| Operation | Automated conveyor and boom system for bulk cargo unloading | Manual or semi-automated grab bucket using crane for cargo handling |

| Efficiency | High unloading speed (up to 5,000+ tons/hour) | Moderate speed, dependent on operator skill and grab size |

| Crew Requirement | Minimal crew due to automation | Higher crew involvement for operation and maintenance |

| Cargo Types | Dry bulk cargo: coal, grain, ore, cement | Bulk and breakbulk, suitable for irregular or mixed cargo |

| Port Infrastructure | Requires specialized unloading terminals or shipboard conveyors | Flexible, usable at standard ports without dedicated infrastructure |

| Cost | Higher initial investment and maintenance cost | Lower capital and maintenance expenses |

| Environmental Impact | Less spillage and dust emission due to enclosed systems | Higher risk of spillage and dust during unloading |

| Typical Use Case | Large bulk carriers with frequent, fast unloading needs | Smaller vessels or ports without specialized facilities |

Introduction to Bulk Material Unloading Systems

Bulk material unloading systems are essential for efficient cargo handling in industries such as shipping, mining, and construction. Self-unloading systems use conveyor belts or pneumatic mechanisms integrated into the vessel, enabling continuous discharge of materials without external equipment. Grab unloaders rely on cranes equipped with a grab bucket, requiring additional machinery and longer unloading times, affecting your operational efficiency.

What is a Self-Unloading System?

A self-unloading system is an integrated mechanism on bulk carriers that enables automatic discharge of cargo without external equipment, using conveyors or articulated booms. It enhances operational efficiency by reducing unloading time and labor costs, especially for materials like coal, grain, or ore. Compared to grab unloaders, self-unloading systems offer continuous flow and greater control over the unloading process, minimizing port dependency and downtime.

Overview of Grab Unloaders

Grab unloaders employ mechanical claws or buckets to lift bulk materials from ships, offering precise control for handling diverse cargo types. These systems excel in environments requiring selective unloading and minimal material spillage. Compared to self-unloading systems, grab unloaders provide flexibility for various vessel designs without integrated conveyor mechanisms.

Key Technological Differences

Self-unloading systems utilize conveyor belts or augers integrated into the vessel, enabling efficient bulk cargo discharge without external equipment, whereas grab unloaders rely on crane-mounted grabs to physically scoop and transfer materials. The self-unloading technology offers continuous and faster unloading times, reducing port expenses and turnaround, while grab unloaders provide flexibility for diverse cargo types and uneven storage. Your choice between these systems should consider operational efficiency needs, cargo characteristics, and port infrastructure compatibility.

Efficiency and Operational Speed Comparison

Self-unloading systems offer superior efficiency and faster operational speed compared to grab unloaders by utilizing integrated conveyor mechanisms that automate material discharge. Grab unloaders rely on mechanical arms or cranes, which require manual control and are generally slower, resulting in longer unloading times and increased labor costs. Your choice of unloading method can significantly impact turnaround times, with self-unloading systems providing streamlined operations ideal for high-volume, time-sensitive cargo handling.

Energy Consumption and Environmental Impact

Self-unloading systems typically consume less energy compared to grab unloaders due to their automated conveyor and hydraulic mechanisms that optimize material handling efficiency. This reduced energy consumption directly lowers greenhouse gas emissions and minimizes your vessel's environmental footprint during cargo discharge operations. Grab unloaders rely on mechanically intensive lifting actions, often resulting in higher fuel use and noise pollution, which can adversely affect both operational costs and marine ecosystems.

Manpower and Safety Considerations

Self-unloading systems reduce manpower requirements by automating cargo discharge, minimizing the need for manual labor and lowering associated labor costs. These systems enhance safety by limiting human exposure to hazardous conditions such as heavy loads and moving equipment, thereby decreasing the risk of workplace injuries. In contrast, grab unloaders require more personnel to operate cranes and manage cargo, increasing both labor intensity and potential safety hazards.

Cost Analysis: Installation and Maintenance

Self-unloading systems typically require a higher initial installation cost due to integrated conveyor mechanisms and automation technology, but they offer lower ongoing operational expenses by reducing manual labor and unloading time. Grab unloaders feature lower upfront installation costs, relying on simpler crane or grab bucket setups, yet demand higher maintenance and labor costs because of frequent mechanical wear and dependence on operators. Long-term cost analysis favors self-unloading systems for bulk carriers prioritizing efficiency and reduced downtime despite substantial initial investment.

Ideal Applications for Each System

Self-unloading systems are ideal for bulk materials like coal, grain, and aggregates, enabling efficient unloading directly from the vessel without external equipment. Grab unloaders excel in handling mixed cargos, heavy items, and irregularly shaped materials at ports with limited infrastructure, offering flexibility and precision. Your choice depends on cargo type and operational environment, optimizing unloading efficiency and cost-effectiveness.

Future Trends in Bulk Unloading Technology

Emerging bulk unloading technologies emphasize automation and energy efficiency, with self-unloading systems integrating advanced sensors and AI to optimize material flow and reduce labor dependency. Grab unloaders are evolving through enhanced hydraulic precision and remote operation capabilities, improving speed and safety in diverse port environments. Future trends indicate a convergence of these technologies toward hybrid systems that combine robotic grabbers with self-unloading conveyors for maximal operational flexibility and minimal environmental impact.

Self-unloading system vs grab unloader Infographic

libmatt.com

libmatt.com