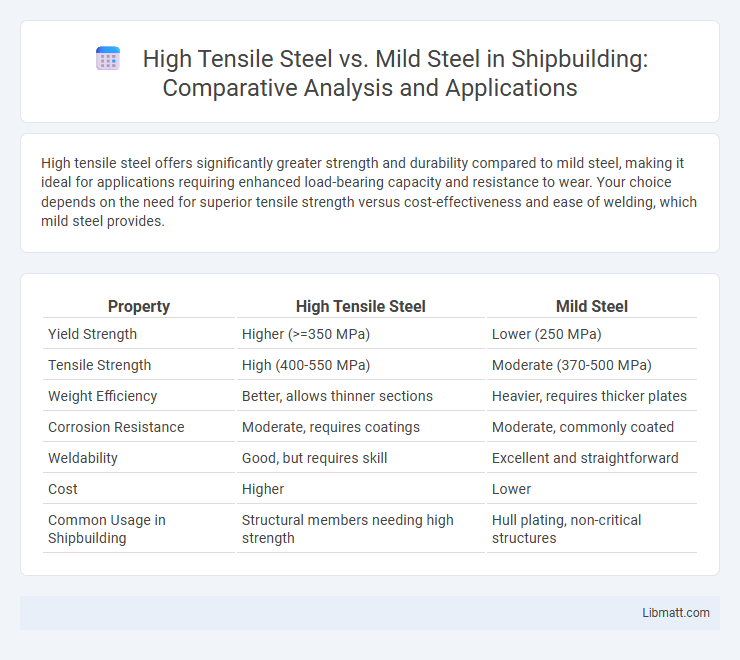

High tensile steel offers significantly greater strength and durability compared to mild steel, making it ideal for applications requiring enhanced load-bearing capacity and resistance to wear. Your choice depends on the need for superior tensile strength versus cost-effectiveness and ease of welding, which mild steel provides.

Table of Comparison

| Property | High Tensile Steel | Mild Steel |

|---|---|---|

| Yield Strength | Higher (>=350 MPa) | Lower (250 MPa) |

| Tensile Strength | High (400-550 MPa) | Moderate (370-500 MPa) |

| Weight Efficiency | Better, allows thinner sections | Heavier, requires thicker plates |

| Corrosion Resistance | Moderate, requires coatings | Moderate, commonly coated |

| Weldability | Good, but requires skill | Excellent and straightforward |

| Cost | Higher | Lower |

| Common Usage in Shipbuilding | Structural members needing high strength | Hull plating, non-critical structures |

Introduction to High Tensile Steel and Mild Steel

High tensile steel exhibits superior strength and durability compared to mild steel, making it ideal for construction and automotive applications requiring enhanced load-bearing capacity. Mild steel contains a lower carbon content, resulting in increased malleability and ease of fabrication, suitable for general-purpose uses. The distinct chemical compositions and mechanical properties govern their respective performance in structural and manufacturing contexts.

Chemical Composition Differences

High tensile steel contains higher carbon content, typically ranging from 0.25% to 0.55%, compared to mild steel's lower carbon range of 0.05% to 0.25%, which directly influences their strength and ductility. It also often includes alloying elements such as manganese, chromium, and nickel that enhance tensile strength and hardness, whereas mild steel has minimal alloying components, prioritizing malleability and ease of welding. Your choice between these steels should consider the specific chemical composition to match the required mechanical properties for your application.

Mechanical Properties Comparison

High tensile steel exhibits superior mechanical properties compared to mild steel, including significantly higher tensile strength, yield strength, and hardness, making it ideal for applications requiring enhanced durability and load-bearing capacity. Mild steel offers greater ductility and ease of welding, which benefits projects needing flexibility and simpler fabrication processes. Understanding these differences ensures your selection aligns with the mechanical demands of your specific application.

Strength and Durability

High tensile steel offers significantly greater strength and durability compared to mild steel due to its higher carbon content and alloying elements, making it ideal for applications requiring superior load-bearing capacity and resistance to wear. While mild steel is more ductile and easier to weld, it lacks the tensile strength and toughness that high tensile steel provides, which ensures longer service life under stress and harsh conditions. Choosing high tensile steel for your projects guarantees enhanced structural integrity and less frequent maintenance.

Weight and Density Considerations

High tensile steel exhibits a higher strength-to-weight ratio compared to mild steel, allowing structures to achieve equivalent durability with less material, thus reducing overall weight. Its density is similar to mild steel, approximately 7.85 g/cm3, but the enhanced mechanical properties mean you can use thinner sections without compromising strength. This weight efficiency makes high tensile steel ideal for applications where minimizing mass is critical, such as in automotive and aerospace industries.

Applications in Industry

High tensile steel is extensively used in automotive manufacturing and construction due to its superior strength and durability, enabling lighter yet stronger vehicle frames and structural components. Mild steel, known for its ease of welding and formability, is preferred in applications such as pipelines, general fabrication, and machinery parts where ductility is crucial. Your choice between these steels depends on the specific industry requirements for strength, flexibility, and cost-effectiveness.

Cost and Availability

High tensile steel typically costs more than mild steel due to its enhanced strength and specialized manufacturing processes. Mild steel is widely available and more affordable, making it suitable for general construction and manufacturing needs. Your choice between the two should consider budget constraints and the specific strength requirements of your project.

Welding and Fabrication Differences

High tensile steel requires specialized welding techniques due to its higher carbon content, which increases the risk of cracking and requires controlled heat input, while mild steel is more forgiving and easier to weld using standard procedures. Fabrication of high tensile steel demands precise handling and often preheating to maintain its mechanical properties, whereas mild steel allows for simpler cutting and shaping processes. Your choice between these materials should consider their welding and fabrication requirements to ensure structural integrity and cost-effectiveness in your project.

Corrosion Resistance

High tensile steel exhibits superior corrosion resistance compared to mild steel due to its alloy composition, which often includes elements like chromium and nickel that enhance durability. Mild steel, with lower alloy content, is more prone to rust and requires protective coatings for prolonged use in corrosive environments. Choosing high tensile steel for your projects ensures greater longevity and reduced maintenance in applications exposed to moisture or harsh conditions.

Choosing the Right Steel for Your Project

High tensile steel offers superior strength and durability compared to mild steel, making it ideal for projects requiring high load-bearing capacity and resistance to wear. Mild steel is more ductile and easier to weld, which suits applications where flexibility and cost-effectiveness are priorities. Selecting between high tensile steel and mild steel depends on factors like structural requirements, environmental conditions, and budget constraints to ensure optimal performance and longevity.

High tensile steel vs mild steel Infographic

libmatt.com

libmatt.com