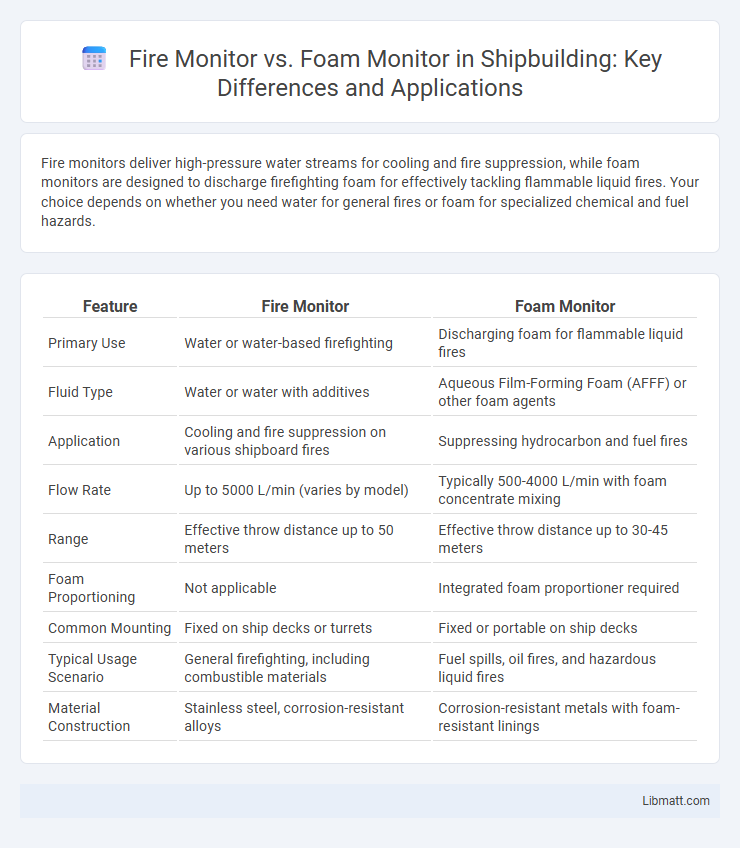

Fire monitors deliver high-pressure water streams for cooling and fire suppression, while foam monitors are designed to discharge firefighting foam for effectively tackling flammable liquid fires. Your choice depends on whether you need water for general fires or foam for specialized chemical and fuel hazards.

Table of Comparison

| Feature | Fire Monitor | Foam Monitor |

|---|---|---|

| Primary Use | Water or water-based firefighting | Discharging foam for flammable liquid fires |

| Fluid Type | Water or water with additives | Aqueous Film-Forming Foam (AFFF) or other foam agents |

| Application | Cooling and fire suppression on various shipboard fires | Suppressing hydrocarbon and fuel fires |

| Flow Rate | Up to 5000 L/min (varies by model) | Typically 500-4000 L/min with foam concentrate mixing |

| Range | Effective throw distance up to 50 meters | Effective throw distance up to 30-45 meters |

| Foam Proportioning | Not applicable | Integrated foam proportioner required |

| Common Mounting | Fixed on ship decks or turrets | Fixed or portable on ship decks |

| Typical Usage Scenario | General firefighting, including combustible materials | Fuel spills, oil fires, and hazardous liquid fires |

| Material Construction | Stainless steel, corrosion-resistant alloys | Corrosion-resistant metals with foam-resistant linings |

Understanding Fire Monitors: Definition and Functions

Fire monitors are high-capacity devices designed to project water or firefighting foam over long distances to control and extinguish fires effectively. Foam monitors specifically discharge firefighting foam, which creates a blanket that suppresses flammable vapors and cools surfaces, making them ideal for flammable liquid fires. Both types of monitors are integral to industrial fire protection systems, with foam monitors preferred for chemical and fuel fires due to their specialized extinguishing properties.

What Are Foam Monitors? Key Features Explained

Foam monitors are specialized firefighting devices designed to project foam over flammable liquid fires, effectively suppressing vapors and cooling the fire. Key features include adjustable flow rates, durable construction for harsh environments, and compatibility with various foam concentrates to optimize fire suppression. Your choice between fire monitors and foam monitors depends on the specific fire hazards and foam application needs for maximum safety and efficiency.

Core Differences Between Fire Monitors and Foam Monitors

Fire monitors primarily deliver water or water-based solutions to control and suppress fires, focusing on cooling and extinguishing flames through high-volume water discharge. Foam monitors, however, are designed to project firefighting foam concentrate mixed with water, creating a foam blanket that smothers fires by cutting off oxygen and preventing vapor release, especially effective on flammable liquid fires. The core difference lies in their application: fire monitors suit general fire suppression with water, while foam monitors specialize in tackling fuel-based fires by deploying foam for enhanced fire suppression capabilities.

Applications of Fire Monitors in Industrial Settings

Fire monitors in industrial settings are essential for high-capacity water delivery to suppress large-scale fires involving flammable liquids, chemicals, or heavy machinery. These monitors provide precise targeting and continuous flow, making them ideal for refineries, chemical plants, and storage facilities where rapid fire containment is critical. Your safety protocols benefit from fire monitors' durability and operational control, enabling effective management of hazardous material fires.

Where Foam Monitors Excel: Typical Use Cases

Foam monitors excel in firefighting scenarios involving flammable liquid fires, such as chemical plants, oil refineries, and fuel storage facilities, where they effectively suppress vapors and cool surfaces. Their ability to deliver expanded foam blankets helps prevent fire re-ignition and enhances safety during hazardous materials incidents. Foam monitors are also ideal for airports and industrial settings requiring rapid, large-volume foam application to control and extinguish hydrocarbon fires.

Performance Comparison: Fire Monitor vs Foam Monitor

Fire monitors deliver high-velocity water streams ideal for cooling and fire suppression over long distances, while foam monitors excel in generating expanded foam for suppressing flammable liquid fires and enhancing fire control. Performance metrics show fire monitors achieve greater flow rates and reach beyond 200 feet, whereas foam monitors provide efficient foam expansion ratios critical for smothering hydrocarbon fires. Your choice depends on whether rapid water delivery or specialized foam application is essential for effective fire management.

Installation Requirements: Fire Monitors vs Foam Monitors

Fire monitors require robust mounting foundations designed to withstand high water pressure and vibration, often necessitating fixed or semi-fixed installations on stable platforms or vehicles. Foam monitors demand precise placement near foam concentrate sources and proportioning equipment to ensure effective foam delivery, often involving portable or stationary setups tailored to specific firefighting scenarios. Both systems must comply with safety standards and accessibility criteria to optimize operational performance and maintenance.

Maintenance and Durability Considerations

Fire monitors require regular inspection and lubrication of moving parts to ensure reliability under high-pressure water flow, with durable materials like stainless steel minimizing corrosion risks. Foam monitors demand additional maintenance for foam concentrate delivery systems, including checking seals and valves to prevent leaks and buildup. Both types benefit from robust corrosion-resistant coatings, but foam monitors typically face more complex upkeep due to the chemical properties of foam agents.

Choosing the Right System for Your Facility

Selecting the appropriate fire suppression system hinges on the specific hazards and materials handled within your facility. Fire monitors deliver powerful water streams ideal for cooling and controlling flames in industrial settings, whereas foam monitors excel in suppressing flammable liquid fires by forming a protective barrier that inhibits vapor release. Evaluating the potential fire risks, compatibility with existing safety protocols, and environmental considerations ensures optimal protection and compliance.

Cost Analysis: Fire Monitor vs Foam Monitor Solutions

Fire monitors generally incur higher upfront costs due to robust materials and advanced control systems, but offer extended durability and lower maintenance expenses. Foam monitors typically present lower initial investment, yet their specialized foam delivery components may lead to increased operational and replacement costs over time. Evaluating total cost of ownership, including installation, maintenance, and consumables, is crucial in selecting between fire monitor and foam monitor solutions.

Fire monitor vs foam monitor Infographic

libmatt.com

libmatt.com