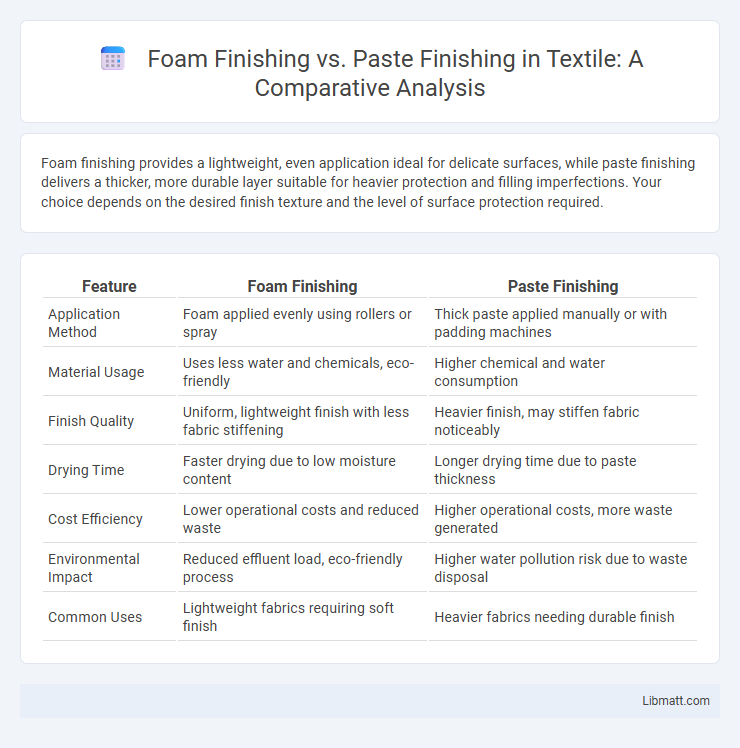

Foam finishing provides a lightweight, even application ideal for delicate surfaces, while paste finishing delivers a thicker, more durable layer suitable for heavier protection and filling imperfections. Your choice depends on the desired finish texture and the level of surface protection required.

Table of Comparison

| Feature | Foam Finishing | Paste Finishing |

|---|---|---|

| Application Method | Foam applied evenly using rollers or spray | Thick paste applied manually or with padding machines |

| Material Usage | Uses less water and chemicals, eco-friendly | Higher chemical and water consumption |

| Finish Quality | Uniform, lightweight finish with less fabric stiffening | Heavier finish, may stiffen fabric noticeably |

| Drying Time | Faster drying due to low moisture content | Longer drying time due to paste thickness |

| Cost Efficiency | Lower operational costs and reduced waste | Higher operational costs, more waste generated |

| Environmental Impact | Reduced effluent load, eco-friendly process | Higher water pollution risk due to waste disposal |

| Common Uses | Lightweight fabrics requiring soft finish | Heavier fabrics needing durable finish |

Introduction to Textile Finishing Techniques

Foam finishing and paste finishing are essential textile finishing techniques that enhance fabric texture, appearance, and performance. Foam finishing uses low-water foam to apply chemicals evenly, reducing water consumption and enabling precise control over chemical penetration. Paste finishing involves applying thick chemical pastes, ideal for heavy or dense fabrics requiring substantial finish layers for improved durability and functional properties.

What is Foam Finishing?

Foam finishing is a surface treatment process that uses a foam-based abrasive to gently smooth and polish materials, enhancing texture and appearance without causing damage. This method is especially effective for delicate substrates like leather, wood, and soft metals, as the foam conforms to irregular surfaces, providing consistent contact and uniform finishing. Your choice of foam finishing can result in a refined, high-quality finish while minimizing material loss compared to traditional paste finishing techniques.

What is Paste Finishing?

Paste finishing is a surface treatment process that uses a viscous compound containing fine abrasives to smooth and polish materials, typically metals or wood. This method enhances surface texture by filling minor imperfections and providing a high-gloss finish, resulting in improved appearance and durability. Commonly applied in industries like automotive and furniture manufacturing, paste finishing offers precise control over the final surface quality.

Key Processes in Foam and Paste Finishing

Foam finishing involves applying a lightweight, aerated compound that enhances surface smoothness through gentle abrasion and quick drying, ideal for delicate materials. Paste finishing utilizes a denser abrasive paste that provides deeper surface leveling and polishing, often used for more durable substrates requiring thorough defect removal. Both processes rely on controlled pressure and precise application techniques to achieve optimal surface quality tailored to specific finishing requirements.

Chemical Applications in Both Finishing Methods

Foam finishing utilizes chemical agents such as surfactants, leveling agents, and defoamers to ensure uniform application and controlled drying on delicate surfaces, promoting smooth textures without excessive absorption. Paste finishing incorporates thicker chemical formulations like binders, thickeners, and abrasives that provide enhanced leveling and fill capabilities, ideal for correcting surface imperfections and achieving high gloss finishes. Both methods rely on tailored chemical compositions to optimize adhesion, drying time, and surface durability according to specific substrate requirements.

Efficiency and Cost Comparison

Foam finishing offers higher efficiency with faster application and drying times, reducing labor costs and increasing production throughput. Paste finishing, while slower and more labor-intensive, provides a thicker protective layer that may reduce the frequency of reapplication, potentially lowering long-term costs. Your choice depends on balancing immediate efficiency gains from foam finishing against the durability and cost-effectiveness of paste finishing over time.

Environmental Impact: Foam vs Paste Finishing

Foam finishing typically has a lower environmental impact compared to paste finishing due to its reduced water usage and biodegradable formulations. Paste finishing often involves higher chemical concentrations and generates more waste, increasing its ecological footprint. When choosing your finishing method, consider foam for a more sustainable and eco-friendly option.

Quality and Performance of Finished Textiles

Foam finishing delivers uniform application and precise control over chemical distribution, enhancing the quality and performance of finished textiles by improving fabric hand feel and durability. Paste finishing offers superior penetration and better gloss, resulting in richer texture and increased fabric strength, ideal for heavy or textured materials. Your choice between foam and paste finishing directly influences the final textile's quality, affecting factors like color uniformity, fabric softness, and performance under stress.

Industrial Applications and Suitability

Foam finishing excels in industrial applications requiring uniform surface texture and precise control, commonly used in electronics, automotive, and medical device manufacturing due to its gentle abrasion and adaptability to complex shapes. Paste finishing offers robust material removal and enhanced surface polishing, making it suitable for heavy-duty metalworking, aerospace, and tooling industries where durability and fine surface quality are critical. Your choice between foam and paste finishing should align with the specific material properties and finish quality demands of your industrial application.

Choosing the Right Finishing Method for Your Needs

Foam finishing provides a smooth, even texture ideal for delicate surfaces and quick drying times, making it suitable for lightweight projects or sensitive materials. Paste finishing offers a thicker, more durable coat that enhances protection and longevity, preferred for heavy-duty applications requiring robust wear resistance. Selecting between foam and paste finishing depends on the project's material sensitivity, desired durability, and texture preferences to achieve optimal results.

Foam finishing vs Paste finishing Infographic

libmatt.com

libmatt.com