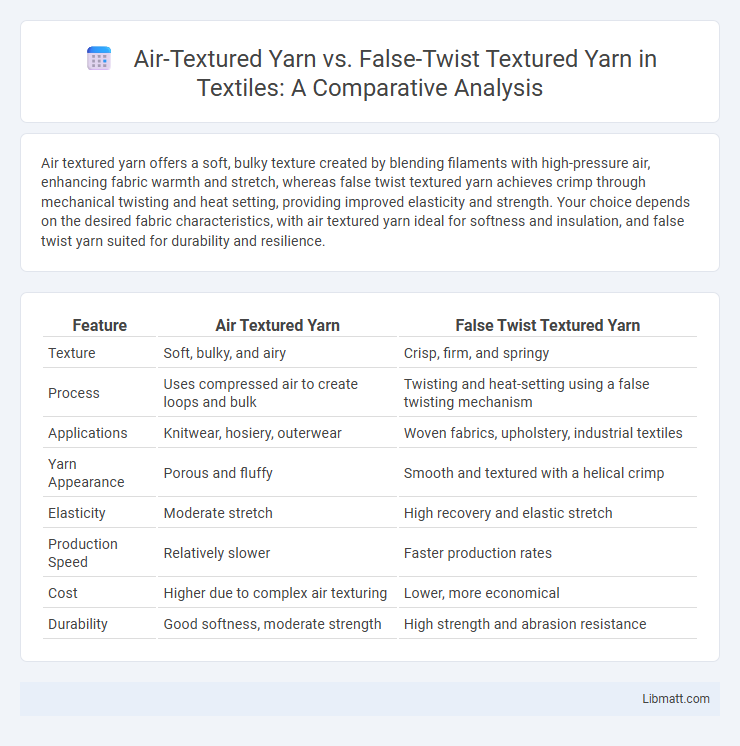

Air textured yarn offers a soft, bulky texture created by blending filaments with high-pressure air, enhancing fabric warmth and stretch, whereas false twist textured yarn achieves crimp through mechanical twisting and heat setting, providing improved elasticity and strength. Your choice depends on the desired fabric characteristics, with air textured yarn ideal for softness and insulation, and false twist yarn suited for durability and resilience.

Table of Comparison

| Feature | Air Textured Yarn | False Twist Textured Yarn |

|---|---|---|

| Texture | Soft, bulky, and airy | Crisp, firm, and springy |

| Process | Uses compressed air to create loops and bulk | Twisting and heat-setting using a false twisting mechanism |

| Applications | Knitwear, hosiery, outerwear | Woven fabrics, upholstery, industrial textiles |

| Yarn Appearance | Porous and fluffy | Smooth and textured with a helical crimp |

| Elasticity | Moderate stretch | High recovery and elastic stretch |

| Production Speed | Relatively slower | Faster production rates |

| Cost | Higher due to complex air texturing | Lower, more economical |

| Durability | Good softness, moderate strength | High strength and abrasion resistance |

Introduction to Textured Yarns

Textured yarns are engineered to enhance fabric properties such as elasticity, appearance, and comfort through specialized processing techniques like air texturing and false twist texturing. Air textured yarn utilizes high-velocity air jets to create bulk and texture by entangling filaments, resulting in a soft, bulky yarn ideal for knitwear and casual apparel. False twist textured yarn undergoes high-speed twisting and heat setting, producing a yarn with high strength, elasticity, and a uniform crimp suitable for technical textiles and performance fabrics.

What is Air Textured Yarn?

Air textured yarn is produced by injecting high-pressure air jets into continuous filament yarn, causing the filaments to entangle and form a bulky, soft, and voluminous structure that mimics spun yarn. This process enhances fabric elasticity, improves insulation, and increases comfort by creating a lightweight texture with a soft hand feel. Air textured yarn is widely used in apparel, home textiles, and technical fabrics due to its blend of durability and natural fiber-like appearance.

What is False Twist Textured Yarn?

False Twist Textured Yarn is a type of textured yarn produced by twisting filaments, heat setting them, and then untwisting to create permanent bulk and stretch. This process imparts excellent elasticity, softness, and smoothness, making the yarn ideal for high-quality apparel and knitted fabrics. Your choice of False Twist Textured Yarn ensures superior durability and versatility for various textile applications compared to Air Textured Yarn.

Production Processes Compared

Air Textured Yarn is produced by inserting high-pressure air jets to create loops and a bulkier texture, resulting in a soft, fluffy feel ideal for knitwear and upholstery. False Twist Textured Yarn undergoes mechanical twisting and heat setting, producing a yarn with high elasticity, smoothness, and bulk, making it suitable for woven fabrics requiring durability and stretch. Understanding these distinct production processes helps you choose the right textured yarn based on your fabric performance and aesthetic needs.

Key Physical Properties Differences

Air Textured Yarn exhibits a softer hand feel and higher bulkiness due to its unique air jet texturing process, which creates a hairier and more voluminous structure. In contrast, False Twist Textured Yarn offers greater tensile strength and better elastic recovery, resulting from the mechanical twisting and untwisting technique that imparts high durability and resilience. Your choice between these yarns depends on the desired fabric characteristics, such as softness versus strength and elasticity.

Applications and End-Uses

Air Textured Yarn is ideal for applications requiring soft hand feel and bulkiness, commonly used in knitting, weaving, and upholstery fabrics, enhancing comfort in apparel and home textiles. False Twist Textured Yarn excels in producing stretchable and resilient fabrics, making it suitable for sportswear, activewear, and hosiery where elasticity and durability are essential. Your choice between these yarns depends on the desired fabric properties and end-use performance requirements.

Advantages of Air Textured Yarn

Air textured yarn offers superior bulk and softness compared to false twist textured yarn, enhancing fabric comfort and appearance. It provides better moisture absorption and breathability, making it ideal for high-performance and casual apparel. The process is more energy-efficient and produces less yarn damage, resulting in higher durability and consistent quality.

Benefits of False Twist Textured Yarn

False Twist Textured Yarn offers superior elasticity and durability compared to Air Textured Yarn, making it ideal for applications requiring high tensile strength and resilience. Its enhanced texture uniformity improves fabric appearance and feel, contributing to better garment performance and longevity. The false twist process also allows for greater control over yarn bulkiness and twist levels, optimizing fabric characteristics for diverse textile products.

Performance and Durability Comparison

Air textured yarn offers superior bulkiness and softness while maintaining excellent tensile strength, making it ideal for lightweight and breathable fabrics. False twist textured yarn exhibits higher durability and better dimensional stability, suitable for applications requiring long-lasting stretch and resilience. Your choice depends on whether enhanced comfort or extended lifespan is the priority in fabric performance.

Choosing Between Air Textured and False Twist Textured Yarn

Choosing between air textured yarn and false twist textured yarn depends on your desired fabric properties and end-use requirements. Air textured yarn offers a soft, bulky feel with enhanced volume and stretch, making it ideal for knitwear and casual apparel, while false twist textured yarn provides high strength, durability, and a smooth, uniform surface suitable for woven fabrics and industrial applications. Understanding your project's need for texture, resilience, and appearance will guide your decision in selecting the optimal yarn type for superior performance.

Air Textured Yarn vs False Twist Textured Yarn Infographic

libmatt.com

libmatt.com