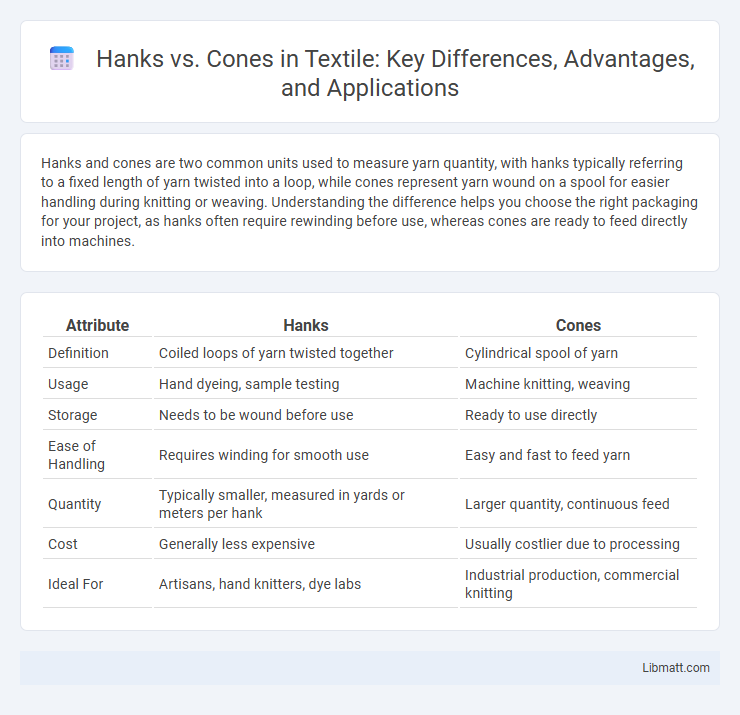

Hanks and cones are two common units used to measure yarn quantity, with hanks typically referring to a fixed length of yarn twisted into a loop, while cones represent yarn wound on a spool for easier handling during knitting or weaving. Understanding the difference helps you choose the right packaging for your project, as hanks often require rewinding before use, whereas cones are ready to feed directly into machines.

Table of Comparison

| Attribute | Hanks | Cones |

|---|---|---|

| Definition | Coiled loops of yarn twisted together | Cylindrical spool of yarn |

| Usage | Hand dyeing, sample testing | Machine knitting, weaving |

| Storage | Needs to be wound before use | Ready to use directly |

| Ease of Handling | Requires winding for smooth use | Easy and fast to feed yarn |

| Quantity | Typically smaller, measured in yards or meters per hank | Larger quantity, continuous feed |

| Cost | Generally less expensive | Usually costlier due to processing |

| Ideal For | Artisans, hand knitters, dye labs | Industrial production, commercial knitting |

Introduction: Understanding Hanks and Cones

Hanks and cones are common yarn packaging forms used in textile production, each serving specific purposes for fiber handling and processing. A hank is a looped length of yarn typically measuring 840 yards for cotton or 560 yards for wool, facilitating easy dyeing and inspection for quality. Cones are cylindrical spools designed for efficient unwinding during weaving or knitting, optimizing tension control and reducing yarn waste.

Definition and Structure: What Are Hanks and Cones?

Hanks are loosely coiled lengths of yarn, typically used for hand-dyeing and winding, allowing easy access to the fibers for inspection and preparation. Cones are yarn wound tightly around a conical core, designed for efficient feeding in machines during weaving or knitting processes. Both hanks and cones serve distinct purposes in textile production, with hanks offering flexibility and cones providing stability and speed.

Historical Background: Evolution of Thread Packaging

The evolution of thread packaging from traditional spools to innovative formats was significantly influenced by the debate between Hanks and Cones, where Hanks offered loosely wound skeins ideal for hand-dyeing and artisan use, while Cones provided tightly wound threads optimized for industrial sewing machines. This historical shift reflects advancements in textile manufacturing, with Cones gaining prominence due to automation requirements and space-efficient storage, contrasting the artisanal and customizable nature of Hanks. Understanding this progression highlights the balance between mass production efficiency and craft-oriented flexibility in thread packaging development.

Material Types: Hanks vs Cones in Different Fibers

Hanks are typically used for natural fibers such as wool, alpaca, and cotton, providing a loosely wound loop that allows fiber to breathe and remain untangled. Cones are favored for synthetic fibers and blends like polyester or nylon, offering a compact, tightly wound structure that feeds smoothly into machines for weaving or knitting. Choosing between hanks and cones depends on fiber type and intended processing method to ensure optimal handling and quality control.

Storage and Organization: Pros and Cons

Hanks provide compact, tangle-resistant storage ideal for natural fibers like wool, allowing easy access and consistent yarn tension, but they can be cumbersome to wind into balls before use. Cones offer efficient, space-saving organization with yarn wound around a central core, facilitating direct machine use and reducing tangling, though they may be bulky and less suited for delicate fibers. Choosing between hanks and cones depends on fiber type, planned use, and available storage space.

Usage in Textile Arts: Knitting, Weaving, and Beyond

Hanks and cones serve distinct purposes in textile arts, each enhancing your creative process. Hanks, typically soft and loosely coiled, are favored in weaving and hand-dyeing for their ease of manipulation and color examination, while cones provide a steady feed ideal for knitting and machine work, reducing tangles and interruptions. Choosing between hanks and cones depends on your technique and project, influencing fiber handling, tension control, and waste management.

Efficiency in Production and Processing

Hanks versus Cones differ significantly in efficiency during production and processing, with cones offering higher automation potential and faster winding speeds, reducing labor costs and time. Hanks require manual handling and re-winding into cones or balls before use, adding extra processing steps and increasing the risk of tangling or damage during production. Your choice between hanks and cones impacts manufacturing efficiency, inventory management, and overall workflow in textile and yarn industries.

Cost Comparison: Hanks vs Cones

Hanks tend to be more cost-effective than cones due to their larger quantity and reduced packaging expenses, making them ideal for bulk purchases. Cones generally come with higher unit prices because of the added manufacturing processes and standalone packaging. Businesses often choose hanks over cones to minimize costs while maintaining yarn quality and volume.

Sustainability and Environmental Impact

Hanks vs Cones offers eco-friendly alternatives that prioritize sustainability by using biodegradable materials and reducing waste through innovative production processes. Their commitment to minimizing carbon footprint includes sourcing from renewable resources and implementing energy-efficient manufacturing techniques. Your choice of Hanks vs Cones supports environmentally responsible products that contribute to reducing pollution and conserving natural resources.

Choosing the Right Option: Hanks or Cones?

Choosing between hanks and cones depends on your specific project needs and yarn handling preferences. Hanks offer an easier way to soak and dye yarn evenly, while cones provide a more convenient, tangle-free option for direct use in machines or hand knitting. Your decision should factor in the ease of use, storage requirements, and the planned dyeing or crafting process.

Hanks vs Cones Infographic

libmatt.com

libmatt.com