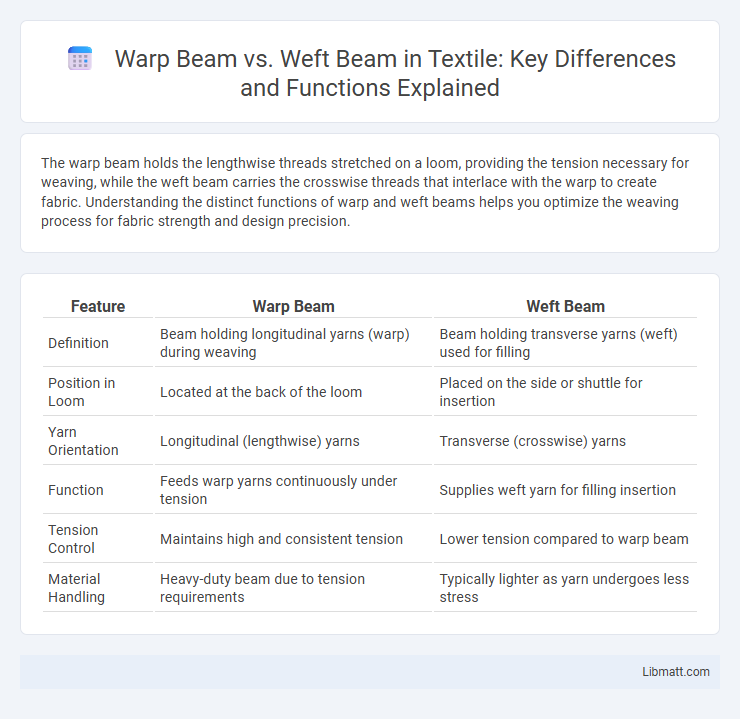

The warp beam holds the lengthwise threads stretched on a loom, providing the tension necessary for weaving, while the weft beam carries the crosswise threads that interlace with the warp to create fabric. Understanding the distinct functions of warp and weft beams helps you optimize the weaving process for fabric strength and design precision.

Table of Comparison

| Feature | Warp Beam | Weft Beam |

|---|---|---|

| Definition | Beam holding longitudinal yarns (warp) during weaving | Beam holding transverse yarns (weft) used for filling |

| Position in Loom | Located at the back of the loom | Placed on the side or shuttle for insertion |

| Yarn Orientation | Longitudinal (lengthwise) yarns | Transverse (crosswise) yarns |

| Function | Feeds warp yarns continuously under tension | Supplies weft yarn for filling insertion |

| Tension Control | Maintains high and consistent tension | Lower tension compared to warp beam |

| Material Handling | Heavy-duty beam due to tension requirements | Typically lighter as yarn undergoes less stress |

Introduction to Warp Beam and Weft Beam

Warp beam and weft beam are essential components in weaving, each serving distinct roles in fabric production. The warp beam holds the longitudinal yarns (warp yarns) under tension, enabling the weaving process to proceed smoothly. In contrast, the weft beam supplies the transverse yarns (weft yarns), which interlace with the warp yarns to form the fabric.

Definition and Core Functions

The warp beam holds the longitudinal threads tightly wound for weaving, ensuring consistent tension and smooth feeding into the loom. The weft beam stores the horizontal weft yarn, facilitating controlled insertion across the warp threads during the fabric formation process. Both beams are essential for maintaining yarn alignment and fabric quality in textile manufacturing.

Structural Differences

The warp beam is a large cylinder located at the back of the loom that holds longitudinal warp yarns tightly wound, ensuring consistent tension during weaving. In contrast, the weft beam, although less common, is used to feed transverse weft yarns and typically features a shorter, wider structure to accommodate the crosswise threads. Structural differences between the warp and weft beams directly impact their function, with the warp beam designed for tension control and the weft beam optimized for thread delivery.

Materials and Construction

Warp beams are typically constructed using high-strength materials such as steel or aluminum to support the heavy tension of warp yarns during weaving. Weft beams, on the other hand, are designed with lighter materials like wood or plastic since they primarily hold the weft yarns, which experience less tension. The construction of warp beams emphasizes durability and rigidity, while weft beams prioritize smooth rotation and ease of yarn delivery.

Role in the Weaving Process

The warp beam holds the longitudinal yarns under tension, supplying a continuous, controlled feed essential for creating the fabric's structure. The weft beam, on the other hand, delivers the horizontal yarns that interlace with the warp yarns through the shuttle or other weft insertion methods, forming the fabric's crosswise pattern. Your understanding of these distinct roles ensures efficient fabric production and quality control during the weaving process.

Advantages and Disadvantages

Warp beams provide consistent tension and alignment for warp yarns, enhancing fabric quality and reducing defects, but their size can limit machine speed and increase setup time. Weft beams allow efficient delivery of filling yarns, improving weaving speed and fabric density, yet they may cause issues with yarn tension variability and potential breakage. Selecting between warp and weft beams depends on fabric type, production speed requirements, and yarn characteristics.

Impact on Fabric Quality

Warp beams provide the longitudinal yarns essential for fabric strength and stability, directly influencing the uniformity and tensile properties of the fabric. Weft beams supply the horizontal yarns that affect fabric texture and elasticity, impacting overall hand feel and appearance. Your fabric quality depends on the precise tension control and alignment of both warp and weft beams to achieve balanced weave structure and minimize defects.

Maintenance and Handling

Warp beams require regular maintenance to ensure tension uniformity and smooth fabric production, involving cleaning and inspection of dents and dents wires to prevent thread breakage. Weft beams demand careful handling to avoid yarn tangling or snagging, with periodic tension adjustments to maintain consistent weft insertion. Proper upkeep of both beams enhances your weaving efficiency and fabric quality.

Technological Advancements

Technological advancements in warp beams have introduced automated tension control systems and electronic monitoring, enhancing precision in yarn delivery and reducing fabric defects. Weft beam technology improvements focus on faster shuttleless looms integration and real-time insertion feedback, increasing weaving efficiency and fabric quality. Innovations in both warp and weft beams contribute to higher productivity and consistent textile manufacturing outcomes.

Choosing the Right Beam for Your Needs

Selecting the right beam--warp or weft--depends on the specific weaving process and fabric requirements, with warp beams supplying longitudinal yarns under tension and weft beams feeding transverse yarns across the loom. Warp beams are crucial for maintaining fabric strength and tension during production, whereas weft beams influence fabric texture and pattern formation. Understanding the tension control, yarn type, and production speed associated with each beam ensures optimal fabric quality and manufacturing efficiency.

Warp beam vs Weft beam Infographic

libmatt.com

libmatt.com