Split fiber features larger, coarser filaments that provide durability and better airflow, making it ideal for heavy-duty cleaning tasks, while microfiber consists of extremely fine synthetic fibers designed to trap smaller particles and allergens, offering superior softness and absorbency. Choosing microfiber enhances Your cleaning efficiency on delicate surfaces and improves dust and dirt removal at a microscopic level.

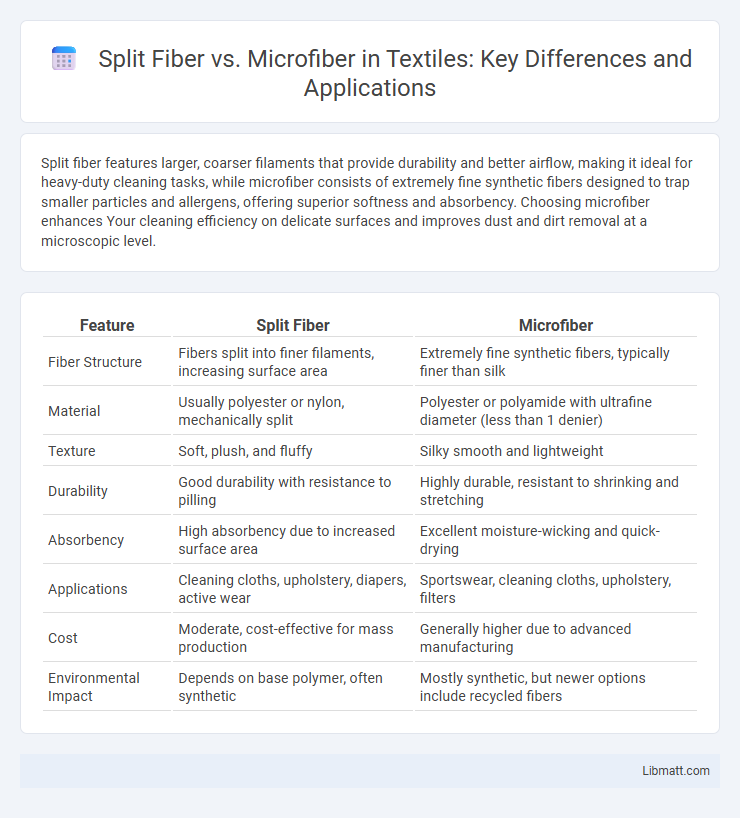

Table of Comparison

| Feature | Split Fiber | Microfiber |

|---|---|---|

| Fiber Structure | Fibers split into finer filaments, increasing surface area | Extremely fine synthetic fibers, typically finer than silk |

| Material | Usually polyester or nylon, mechanically split | Polyester or polyamide with ultrafine diameter (less than 1 denier) |

| Texture | Soft, plush, and fluffy | Silky smooth and lightweight |

| Durability | Good durability with resistance to pilling | Highly durable, resistant to shrinking and stretching |

| Absorbency | High absorbency due to increased surface area | Excellent moisture-wicking and quick-drying |

| Applications | Cleaning cloths, upholstery, diapers, active wear | Sportswear, cleaning cloths, upholstery, filters |

| Cost | Moderate, cost-effective for mass production | Generally higher due to advanced manufacturing |

| Environmental Impact | Depends on base polymer, often synthetic | Mostly synthetic, but newer options include recycled fibers |

Introduction to Split Fiber and Microfiber

Split fiber consists of yarns that have been mechanically split to increase surface area, enhancing softness and absorbency, making them ideal for towels and cleaning products. Microfiber is a synthetic fiber finer than one denier, designed with ultrafine strands that provide superior cleaning efficiency, durability, and moisture-wicking properties. Choosing between split fiber and microfiber depends on your need for texture and performance in applications like textiles or cleaning.

What is Split Fiber?

Split fiber is a type of synthetic fiber created by splitting a single fiber strand into multiple finer filaments, which increases its surface area and enhances properties like softness, absorbency, and durability. This structure allows split fiber fabrics to outperform microfiber in moisture-wicking and drying speed, making them ideal for cleaning cloths and activewear. Your choice of split fiber material can significantly impact the performance and longevity of textile products.

What Defines Microfiber?

Microfiber is defined by its ultrafine synthetic fibers, typically measuring less than 1 denier, which is thinner than a human hair, allowing for exceptional softness and high surface area. These dense fibers enable superior moisture-wicking, quick drying, and enhanced durability compared to standard split fiber fabrics. When choosing microfiber, You benefit from textiles that provide lightweight comfort while maintaining strength and easy maintenance.

Key Differences Between Split Fiber and Microfiber

Split fiber consists of fibers that are physically cut to create multiple fine strands, enhancing softness and insulation, while microfiber is a synthetic fiber typically made from polyester or nylon with a diameter finer than one denier, providing superior strength and moisture-wicking abilities. Split fibers tend to trap more air, offering better thermal properties, whereas microfiber excels in durability, ease of cleaning, and resistance to water absorption. The choice between split fiber and microfiber depends on the desired balance of softness, insulation, breathability, and maintenance requirements in textile applications.

Manufacturing Processes Compared

Split fiber is produced by mechanically splitting synthetic fibers into finer filaments, enhancing softness and insulation properties, whereas microfiber is manufactured by extruding polymers through fine spinnerets to create ultra-fine continuous fibers that offer exceptional strength and smoothness. The split fiber process increases surface area and texture, improving moisture wicking and warmth, while microfiber's manufacturing emphasizes fiber diameter reduction, leading to superior durability and stain resistance. Both fibers utilize advanced extrusion techniques, but split fibers involve an additional mechanical splitting step to modify fiber morphology for specific textile applications.

Performance in Cleaning Applications

Split fiber offers superior performance in cleaning applications due to its increased surface area and enhanced dirt-trapping ability, making it ideal for heavy-duty tasks and removing stubborn grime. Microfiber, composed of ultra-fine fibers less than 1 denier in diameter, excels in capturing dust, bacteria, and moisture with high efficiency, providing streak-free results on delicate surfaces. Both materials outperform traditional fibers, but microfiber's finer structure enables better cleaning precision and faster drying times in professional and household environments.

Durability and Longevity

Split fiber tends to be less durable than microfiber due to its coarser texture, which can lead to quicker wear and tear over time. Microfiber's tightly woven synthetic fibers enhance longevity by resisting stains, fading, and fraying, making it a more robust choice for heavy-use items. Your investment in microfiber products often results in longer-lasting performance with less frequent replacement needed.

Environmental Impact and Sustainability

Split fiber and microfiber differ significantly in environmental impact and sustainability, with split fiber typically made from natural or biodegradable materials, reducing its ecological footprint. Microfiber, composed of synthetic polymers like polyester or nylon, contributes to microplastic pollution during washing and has a longer decomposition time in landfills. Choosing split fiber supports your commitment to sustainability by minimizing plastic waste and promoting eco-friendly textile options.

Cost Analysis: Split Fiber vs Microfiber

Split fiber insulation typically costs less upfront compared to microfiber alternatives due to its simpler manufacturing process and lower raw material expenses. Microfiber insulation offers superior thermal performance and durability, which can lead to long-term energy savings, offsetting its higher initial price. When evaluating your investment, consider both immediate costs and future energy efficiency benefits to determine the most cost-effective solution for your needs.

Which is Better: Split Fiber or Microfiber?

Split fiber offers superior durability and breathability compared to microfiber, making it ideal for products requiring long-lasting comfort and moisture management. Microfiber, composed of ultra-fine synthetic fibers, excels in softness and is often more affordable, providing a cozy feel but may lack the same resilience as split fiber. Your choice depends on whether you prioritize durability and ventilation or softness and cost-effectiveness.

Split Fiber vs Microfiber Infographic

libmatt.com

libmatt.com