Yarn twist refers to the number of turns per unit length that secure fibers together, affecting strength and texture, while yarn crimp describes the waviness or bend in the yarn that influences elasticity and fabric appearance. Understanding the balance between twist and crimp is essential for optimizing your yarn's performance in textile applications.

Table of Comparison

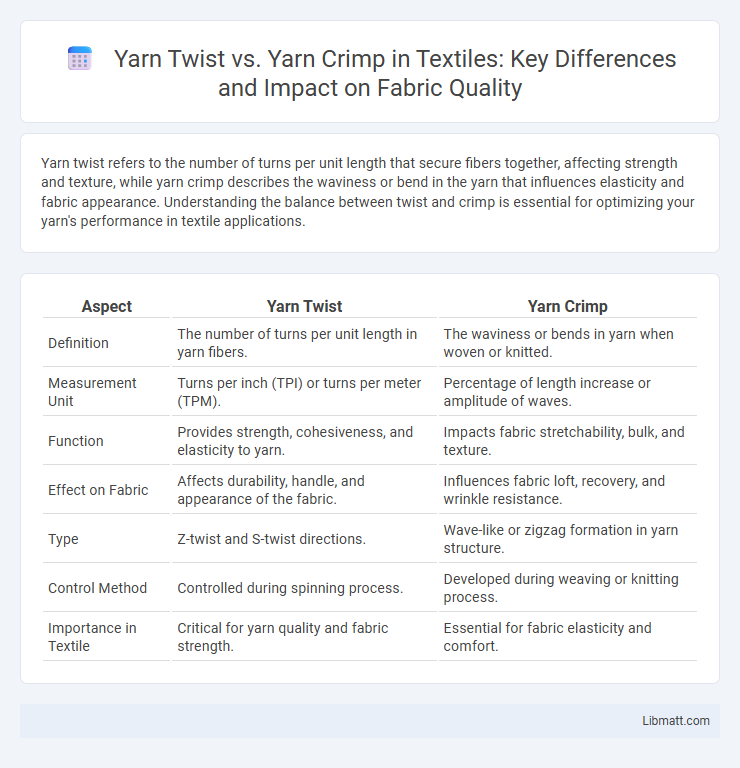

| Aspect | Yarn Twist | Yarn Crimp |

|---|---|---|

| Definition | The number of turns per unit length in yarn fibers. | The waviness or bends in yarn when woven or knitted. |

| Measurement Unit | Turns per inch (TPI) or turns per meter (TPM). | Percentage of length increase or amplitude of waves. |

| Function | Provides strength, cohesiveness, and elasticity to yarn. | Impacts fabric stretchability, bulk, and texture. |

| Effect on Fabric | Affects durability, handle, and appearance of the fabric. | Influences fabric loft, recovery, and wrinkle resistance. |

| Type | Z-twist and S-twist directions. | Wave-like or zigzag formation in yarn structure. |

| Control Method | Controlled during spinning process. | Developed during weaving or knitting process. |

| Importance in Textile | Critical for yarn quality and fabric strength. | Essential for fabric elasticity and comfort. |

Understanding Yarn Twist and Yarn Crimp

Yarn twist refers to the rotational force applied to fibers during spinning to bind them together, affecting yarn strength, elasticity, and texture. Yarn crimp describes the waviness or bends in the yarn structure, contributing to fabric bulk, stretch, and thermal insulation. Understanding the balance between yarn twist and crimp is essential for optimizing textile performance in terms of durability, comfort, and appearance.

Key Differences Between Yarn Twist and Yarn Crimp

Yarn twist refers to the number of turns per unit length imparted to fibers, affecting yarn strength, elasticity, and appearance, while yarn crimp describes the waviness or bends in the fiber or yarn structure that influence bulk, stretchability, and insulation properties. Twist angle and twist level determine yarn tightness and durability, whereas crimp percentage controls yarn resilience and texture in fabrics. Understanding these differences is critical for optimizing yarn performance in textile manufacturing and end-use applications.

Types of Yarn Twist: S-Twist vs Z-Twist

S-twist and Z-twist are the two primary types of yarn twist, each defining the direction fibers are spun to enhance yarn strength and texture. S-twist yarns spiral upward to the left, resembling the central stroke of the letter "S," while Z-twist yarns spiral upward to the right, similar to the central stroke of the letter "Z." Your choice between S-twist and Z-twist affects the fabric's appearance, durability, and compatibility with certain weaving or knitting techniques.

Methods of Achieving Yarn Crimp

Yarn crimp is achieved through mechanical, thermal, or chemical methods that introduce waves or bends in yarn fibers to enhance fabric elasticity and texture. Mechanical crimping involves processes like gear crimping and stuffer box crimping that physically distort the yarn structure. Thermal and chemical methods set crimp by heat treatment or chemical reactions that alter fiber shape at a molecular level, commonly used in synthetic fibers to maintain permanent crimp.

Impact of Twist on Yarn Strength and Elasticity

Yarn twist significantly impacts yarn strength and elasticity by interlocking fibers tightly, enhancing tensile strength and reducing elongation under stress. Higher twist levels increase yarn rigidity and resistance to breakage while decreasing stretchability, making the yarn suitable for durability-demanding applications. Conversely, lower twist results in softer, more elastic yarn but compromises strength, affecting fabric performance in high-stress conditions.

Influence of Crimp on Yarn Bulk and Texture

Crimp significantly increases yarn bulk by introducing waves or bends that create more air pockets within the fabric, enhancing its volume and insulation properties. Higher crimp levels contribute to a softer texture and improved fabric elasticity, essential for comfort and durability in textiles. The interplay between crimp and twist determines the fabric's overall hand feel, resilience, and aesthetic appeal, with crimp having a more direct impact on bulk and texture than twist alone.

Applications of High-Twist vs High-Crimp Yarns

High-twist yarns exhibit increased strength and durability, making them ideal for applications in sewing threads, upholstery fabrics, and industrial textiles requiring high abrasion resistance. High-crimp yarns provide enhanced elasticity and bulk, which is beneficial for knitwear, upholstery, and elastic fabrics that demand stretch and recovery. Your choice between high-twist and high-crimp yarns depends on the need for tensile strength or fabric resilience in specific textile products.

Effects on Fabric Properties: Drape, Stretch, and Appearance

Yarn twist significantly impacts fabric drape by controlling the fiber cohesion, resulting in a smoother surface and enhanced durability, while higher twist levels increase fabric stiffness and reduce softness. Yarn crimp affects stretch and elasticity, with increased crimp offering greater fabric flexibility and improved recovery after deformation, contributing to a more pliable and resilient fabric texture. Your fabric's appearance is influenced by the interplay between twist and crimp, where balanced twist ensures a uniform look, and pronounced crimp enhances texture and visual depth.

Testing and Measuring Yarn Twist and Crimp

Testing yarn twist involves using twist testers that measure the number of turns per inch or centimeter to ensure proper yarn strength and fabric texture. Yarn crimp is measured through crimp contraction methods or microscopic analysis to evaluate fiber waviness, which impacts fabric elasticity and bulk. You can improve product quality by accurately measuring both twist and crimp to optimize fabric performance and durability.

Selecting the Right Yarn: Twist or Crimp for Your Project

Selecting the right yarn involves understanding the impact of twist and crimp on fabric performance and appearance; twist affects yarn strength, smoothness, and durability, while crimp influences elasticity, bulk, and texture. High twist yarns are ideal for projects requiring firm, smooth, and dense fabrics, such as denim and woven garments, whereas crimped yarns provide stretch and softness, suitable for knitwear and upholstery. Evaluating project needs for tensile strength, drape, and comfort helps determine whether a twisted or crimped yarn will yield optimal results.

Yarn twist vs Yarn crimp Infographic

libmatt.com

libmatt.com