Air texturizing uses compressed air to create bulk and texture in synthetic fibers without twisting, resulting in a softer feel with less mechanical stress on the yarn. False twist texturizing involves twisting fibers at high speeds, setting the texture through heat, and then untwisting, producing stronger, more elastic yarn ideal for durable textiles.

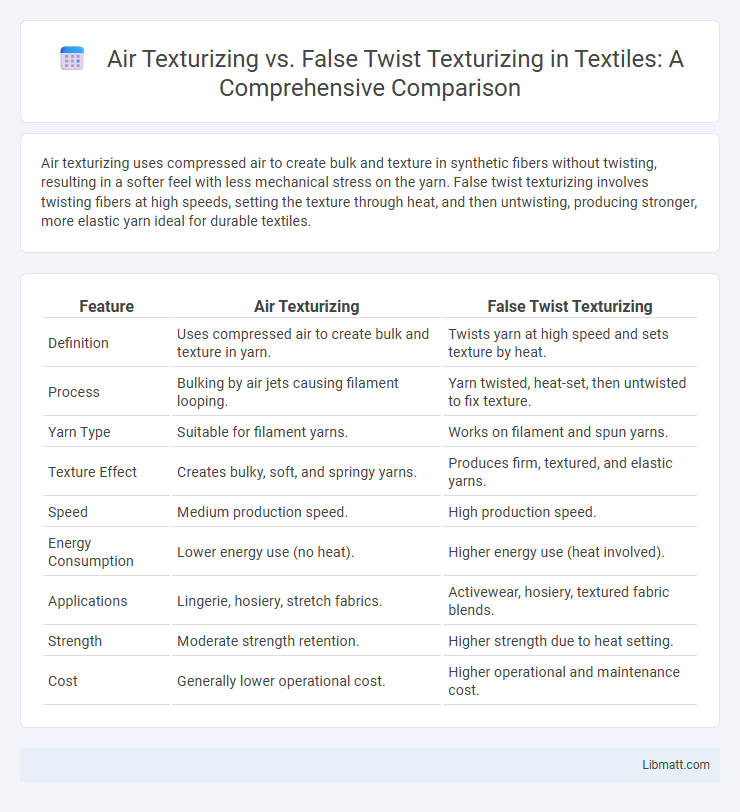

Table of Comparison

| Feature | Air Texturizing | False Twist Texturizing |

|---|---|---|

| Definition | Uses compressed air to create bulk and texture in yarn. | Twists yarn at high speed and sets texture by heat. |

| Process | Bulking by air jets causing filament looping. | Yarn twisted, heat-set, then untwisted to fix texture. |

| Yarn Type | Suitable for filament yarns. | Works on filament and spun yarns. |

| Texture Effect | Creates bulky, soft, and springy yarns. | Produces firm, textured, and elastic yarns. |

| Speed | Medium production speed. | High production speed. |

| Energy Consumption | Lower energy use (no heat). | Higher energy use (heat involved). |

| Applications | Lingerie, hosiery, stretch fabrics. | Activewear, hosiery, textured fabric blends. |

| Strength | Moderate strength retention. | Higher strength due to heat setting. |

| Cost | Generally lower operational cost. | Higher operational and maintenance cost. |

Introduction to Texturizing Techniques

Air texturizing uses compressed air to create soft, airy texture in synthetic yarns by gently separating fibers, enhancing fabric elasticity and comfort. False twist texturizing applies high-speed twisting and heat to create durable, tightly twisted yarns with increased bulk and resilience, ideal for activewear and upholstery. Your choice between these methods depends on the desired fabric properties such as softness versus strength and texture longevity.

Overview of Air Texturizing

Air texturizing uses compressed air to create bulk and texture in synthetic or natural fibers by introducing random crimps without heat. This method preserves fiber strength and enhances softness and volume, making your hair appear fuller and more natural. Unlike false twist texturizing, which applies heat and twisting to form permanent curls, air texturizing offers a gentler treatment ideal for delicate or fine strands.

Overview of False Twist Texturizing

False Twist Texturizing is a widely used mechanical process that imparts bulk and stretch to synthetic yarns by twisting, heat setting, and untwisting the fibers, enhancing fabric elasticity and appearance. This method produces yarns with high uniformity, increased volume, and improved hand feel compared to air texturizing, which relies on compressing and entangling filaments using high-pressure air jets. False Twist Texturizing is favored in applications requiring durable, textured yarns such as hosiery, sportswear, and upholstery fabrics due to its precise control over yarn characteristics.

Key Differences Between Air and False Twist Texturizing

Air texturizing uses compressed air to create bulk and texture in synthetic and natural fibers by forming loops and waves, enhancing fabric volume without applying heat. False twist texturizing involves twisting filaments while heating and then cooling to set a permanent crimp, providing strong elasticity and resilience ideal for performance textiles. The key difference lies in air texturizing being a non-thermal, gentle process for softness and bulk, whereas false twist texturizing is a thermal method that imparts durable stretch and textured structure.

Fiber Types Suitable for Each Method

Air texturizing is ideal for low to medium filament count synthetic fibers such as polyester and nylon, as it gently creates bulk and elasticity without damaging delicate fibers. False twist texturizing suits high-tenacity fibers like nylon and polyester with higher filament counts, providing more permanent texture by applying heat and twist simultaneously. Your choice depends on fiber type and desired texture durability, with air texturizing offering softness and false twist ensuring long-lasting crimp.

Process Steps: Air Texturizing vs False Twist

Air texturizing involves injecting high-pressure air jets into synthetic fibers to create bulk and texture through controlled fiber entanglement and crimping. False twist texturizing uses a mechanical twist combined with heat setting, where the yarn is twisted, heated to set the structure, and then untwisted to produce a permanent textured effect. Your choice between these processes impacts fabric elasticity and appearance, with air texturizing offering higher bulk and false twist providing enhanced stretch and resilience.

End-Use Applications of Air Texturized Yarns

Air texturized yarns are widely used in the production of casual and stretch apparel due to their bulkiness, softness, and enhanced elasticity. These yarns are ideal for knitwear, socks, and activewear fabrics, providing superior comfort and moisture management. Air texturizing is favored in technical textiles where lightweight and breathable properties are essential, such as in automotive and home furnishing applications.

End-Use Applications of False Twist Texturized Yarns

False twist texturized yarns are widely used in applications requiring high bulk, stretch, and durability, such as activewear, hosiery, upholstery, and home textiles. This method enhances yarn elasticity and resilience, making it ideal for garments that demand comfort and shape retention. Your choice of false twist texturized yarn ensures superior performance in products where texture and strength are critical.

Performance and Quality Comparison

Air texturizing utilizes compressed air to create bulk and texture in fibers without mechanical twisting, resulting in a softer hand feel and enhanced fabric breathability. False twist texturizing involves heating and twisting filaments, producing high bulk and elasticity with increased uniformity and durability in performance fabrics. Compared to false twist, air texturizing offers superior softness and reduced fiber damage, while false twist provides better resilience and shape retention, making the choice dependent on specific textile application requirements.

Sustainability and Economic Considerations

Air texturizing consumes less energy than false twist texturizing, making it a more sustainable option for textile production. Your choice impacts operational costs, as air texturizing has lower machine maintenance and energy expenses, whereas false twist texturizing demands higher input but offers greater yarn uniformity. Sustainable manufacturing increasingly values air texturizing for its environmental benefits and cost-effectiveness in medium-scale production.

Air texturizing vs False twist texturizing Infographic

libmatt.com

libmatt.com