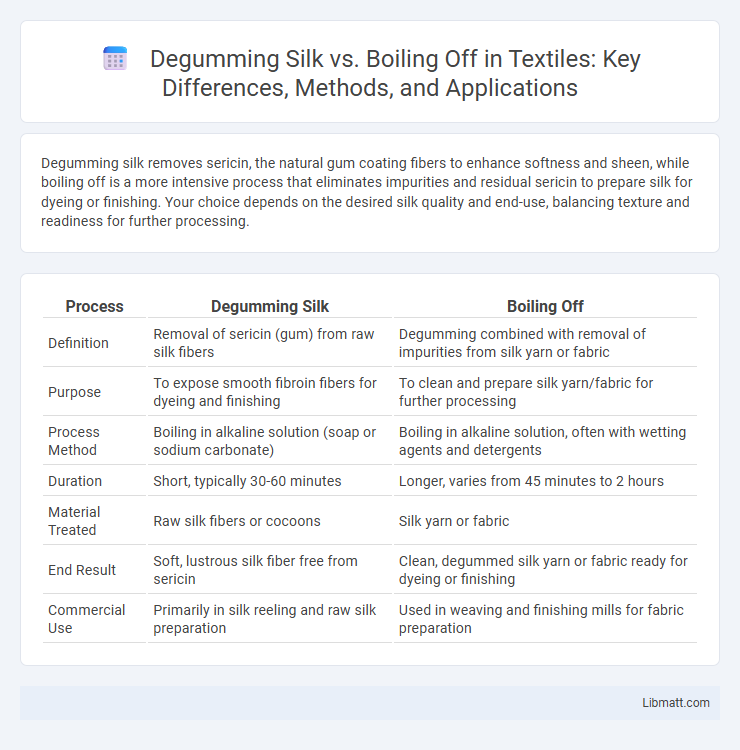

Degumming silk removes sericin, the natural gum coating fibers to enhance softness and sheen, while boiling off is a more intensive process that eliminates impurities and residual sericin to prepare silk for dyeing or finishing. Your choice depends on the desired silk quality and end-use, balancing texture and readiness for further processing.

Table of Comparison

| Process | Degumming Silk | Boiling Off |

|---|---|---|

| Definition | Removal of sericin (gum) from raw silk fibers | Degumming combined with removal of impurities from silk yarn or fabric |

| Purpose | To expose smooth fibroin fibers for dyeing and finishing | To clean and prepare silk yarn/fabric for further processing |

| Process Method | Boiling in alkaline solution (soap or sodium carbonate) | Boiling in alkaline solution, often with wetting agents and detergents |

| Duration | Short, typically 30-60 minutes | Longer, varies from 45 minutes to 2 hours |

| Material Treated | Raw silk fibers or cocoons | Silk yarn or fabric |

| End Result | Soft, lustrous silk fiber free from sericin | Clean, degummed silk yarn or fabric ready for dyeing or finishing |

| Commercial Use | Primarily in silk reeling and raw silk preparation | Used in weaving and finishing mills for fabric preparation |

Introduction to Degumming and Boiling Off in Silk Processing

Degumming silk involves removing sericin, the gummy protein that binds silk fibers, to enhance softness and sheen, while boiling off is a preparatory process using hot water to eliminate impurities and residual sericin from raw silk. Both processes are essential in silk processing to ensure the fibers are clean, smooth, and ready for dyeing or weaving. Effective degumming and boiling off improve silk's texture, dye uptake, and overall fabric quality in textile production.

Understanding the Structure of Raw Silk

Degumming silk removes sericin, the gummy protein coating raw silk fibers, enhancing smoothness and luster by exposing fibroin, the core structural protein responsible for silk's strength and elasticity. Boiling off is a more intensive process that eliminates impurities through prolonged heat treatment, facilitating dye absorption and fabric softness by thoroughly breaking down sericin layers. Understanding the microscopic arrangement of fibroin filaments and sericin's protective matrix clarifies why controlled degumming preserves fiber integrity while boiling off optimizes silk's final texture.

What is Degumming?

Degumming is the process of removing sericin, the gummy protein that binds silk fibers together, to enhance the fabric's softness, sheen, and absorbency. Unlike boiling off, which generally refers to the full scouring process to clean and prepare silk, degumming specifically targets the elimination of sericin without damaging the delicate silk fibers. Proper degumming improves Your silk's texture and dye uptake, making it essential for high-quality silk production.

The Boiling Off Process Explained

The boiling off process removes sericin from silk fibers by immersing them in hot water with mild detergents or alkaline solutions, effectively softening and preparing the fabric for dyeing and finishing. This method differs from simple degumming by using higher temperatures and controlled chemical treatments to eliminate impurities without damaging the silk's natural luster. Understanding boiling off ensures your silk retains optimal texture and absorbency, enhancing both quality and durability.

Key Differences Between Degumming and Boiling Off

Degumming silk primarily involves removing sericin, the gummy substance surrounding silk fibers, to enhance softness and luster, while boiling off refers to a more comprehensive process that removes sericin along with other impurities like waxes and dirt. Degumming targets the silk filament's surface to improve texture, whereas boiling off prepares raw silk for dyeing or finishing by ensuring thorough cleanliness. The degumming process typically uses milder treatments, whereas boiling off employs higher temperatures and alkaline solutions for deep purification.

Effects on Silk Quality and Texture

Degumming silk removes sericin, improving softness and luster without significantly weakening fibers, preserving the fabric's natural sheen and smooth texture. Boiling off, a more aggressive process, eliminates sericin along with impurities but can cause fiber damage, resulting in reduced tensile strength and a rougher texture. Choosing between degumming and boiling off impacts silk quality; degumming maintains delicate handfeel, while boiling off ensures thorough cleansing at the risk of altering fabric softness and durability.

Environmental and Chemical Considerations

Degumming silk involves enzymatic or mild alkaline treatments that use fewer harsh chemicals, reducing water pollution and chemical waste compared to boiling off, which typically requires strong alkalis and prolonged heating, resulting in higher energy consumption and environmental impact. The degumming process prioritizes biodegradable agents, minimizing toxic effluents and facilitating easier wastewater treatment, whereas boiling off releases more alkaline residues that pose challenges for effluent management and soil contamination. Choosing degumming over boiling off aligns with sustainable textile practices by lowering chemical usage and energy demands, thus significantly decreasing the ecological footprint of silk processing.

Industrial Applications and Preferences

Degumming silk involves the removal of sericin to enhance fabric softness and dye absorption, making it preferred in textile manufacturing where fabric quality is critical. Boiling off, a more intensive process that removes sericin along with impurities, is favored in industries requiring high-purity silk for medical sutures or luxury garments. Your choice between degumming and boiling off depends on the end-use requirements and desired silk properties in industrial applications.

Innovations in Silk Processing Techniques

Innovations in silk processing techniques have revolutionized degumming silk and boiling off, enhancing fabric quality and environmental sustainability. Advanced enzymatic degumming processes replace traditional chemical methods, preserving silk's natural luster while reducing water usage and pollution. Your silk products benefit from these cutting-edge methods, ensuring softer texture and improved durability without compromising ecological responsibility.

Choosing the Right Method for Your Silk

Degumming silk involves gently removing sericin to enhance softness, preserving fiber strength and luster, ideal for delicate or high-quality silk. Boiling off uses higher temperatures to eradicate sericin and impurities, suitable for sturdier silk varieties requiring thorough cleaning. Selecting the right method depends on silk type, desired texture, and end-use, ensuring optimal fabric performance and appearance.

Degumming silk vs Boiling off Infographic

libmatt.com

libmatt.com