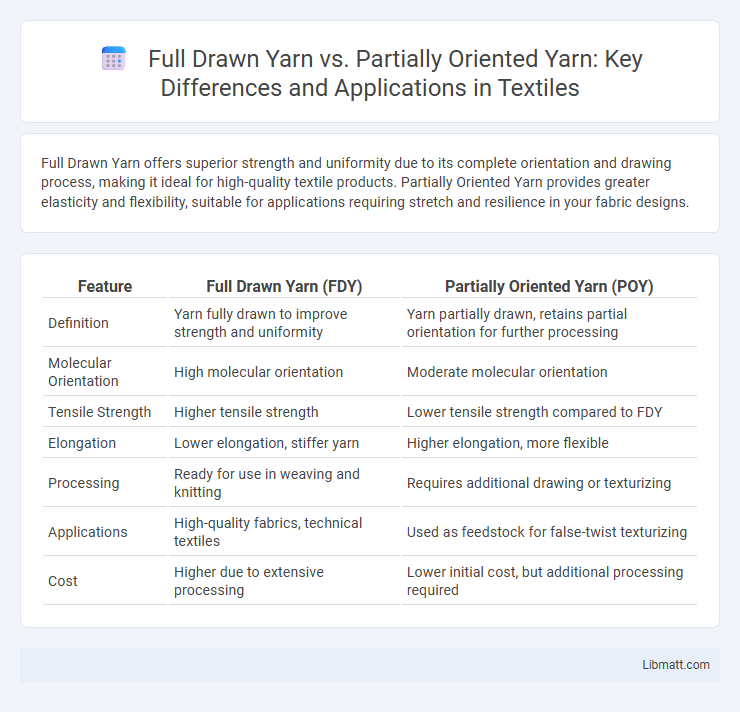

Full Drawn Yarn offers superior strength and uniformity due to its complete orientation and drawing process, making it ideal for high-quality textile products. Partially Oriented Yarn provides greater elasticity and flexibility, suitable for applications requiring stretch and resilience in your fabric designs.

Table of Comparison

| Feature | Full Drawn Yarn (FDY) | Partially Oriented Yarn (POY) |

|---|---|---|

| Definition | Yarn fully drawn to improve strength and uniformity | Yarn partially drawn, retains partial orientation for further processing |

| Molecular Orientation | High molecular orientation | Moderate molecular orientation |

| Tensile Strength | Higher tensile strength | Lower tensile strength compared to FDY |

| Elongation | Lower elongation, stiffer yarn | Higher elongation, more flexible |

| Processing | Ready for use in weaving and knitting | Requires additional drawing or texturizing |

| Applications | High-quality fabrics, technical textiles | Used as feedstock for false-twist texturizing |

| Cost | Higher due to extensive processing | Lower initial cost, but additional processing required |

Introduction to Full Drawn Yarn (FDY) and Partially Oriented Yarn (POY)

Full Drawn Yarn (FDY) is a type of synthetic filament yarn characterized by uniform fiber alignment and enhanced strength, making it ideal for weaving and knitting applications. Partially Oriented Yarn (POY) undergoes partial drawing and orientation, resulting in intermediate properties that require further processing such as texturizing to achieve desired fabric characteristics. Both FDY and POY serve essential roles in textile manufacturing, with FDY offering ready-to-use filament yarn and POY providing a versatile base for downstream textile processes.

Manufacturing Process: FDY vs POY

Full Drawn Yarn (FDY) undergoes a complete drawing and heat-setting process during manufacturing, resulting in a fully oriented fiber with enhanced strength, uniformity, and smoothness. Partially Oriented Yarn (POY) is produced by partially stretching the filament after spinning, creating fibers with moderate orientation that require further drawing to achieve full strength and texture. The FDY process integrates drawing and heat-setting immediately after extrusion, while POY involves a preliminary extrusion and partial drawing stage, followed by additional post-processing to reach desired fiber properties.

Key Differences Between FDY and POY

Full Drawn Yarn (FDY) is fully processed and stretched, offering higher tensile strength and uniformity, while Partially Oriented Yarn (POY) is semi-processed, designed for further drawing or texturizing. FDY provides smoother texture and is ready for direct weaving or knitting, unlike POY, which requires additional processing to achieve final properties. The molecular orientation in FDY is higher, leading to better dimensional stability compared to the less oriented, more flexible POY.

Physical Properties Comparison: FDY vs POY

Full Drawn Yarn (FDY) exhibits superior tensile strength and uniformity compared to Partially Oriented Yarn (POY), making it ideal for high-performance textile applications. FDY's higher molecular orientation results in better dimensional stability and reduced elongation under stress, whereas POY offers greater stretchability but lower mechanical strength. The enhanced physical properties of FDY contribute to improved fabric durability and resistance to deformation in demanding environments.

Applications and End-Uses of FDY

Full Drawn Yarn (FDY) is widely used in applications requiring high strength, excellent dimensional stability, and smooth texture, such as in weaving, knitting, and industrial fabrics. Its end-uses include production of garments, home textiles, and technical textiles like airbags and conveyor belts, where consistent quality and durability are essential. You can rely on FDY for enhanced performance in products demanding uniformity and resilience.

Applications and End-Uses of POY

Partially Oriented Yarn (POY) is primarily used as an intermediate product in the textile industry, serving as the raw material for producing Fully Drawn Yarn (FDY) through processes like drawing and texturizing. POY finds applications in manufacturing synthetic fibers for knitting, weaving, and industrial textiles such as tire cords, conveyor belts, and non-woven fabrics. Your choice of yarn type depends on the desired strength, texture, and end-use, with POY offering versatility for various synthetic fabric applications.

Advantages of Using FDY

Full Drawn Yarn (FDY) offers superior strength and uniformity compared to Partially Oriented Yarn (POY), resulting in enhanced fabric durability and smooth texture. FDY's high tensile strength improves garment performance, making it ideal for applications requiring resilience and consistent quality. Your textile products benefit from FDY's immediate usability without the need for additional processing, reducing manufacturing time and costs.

Benefits of Utilizing POY

Partially Oriented Yarn (POY) offers significant benefits over Full Drawn Yarn (FDY), including greater flexibility in downstream processing such as drawing and texturizing, which allows for customized fabric properties. POY's semi-finished nature reduces production costs and enables manufacturers to produce a wide variety of textile products tailored to specific applications. Your choice of POY can optimize both the efficiency and versatility of your textile manufacturing process.

Cost Implications: FDY vs POY

Full Drawn Yarn (FDY) generally incurs higher production costs due to its additional drawing and texturizing processes compared to Partially Oriented Yarn (POY), which is produced through fewer processing steps. The increased energy consumption and specialized machinery required for FDY contribute to its elevated price point in the textile market. Conversely, POY often offers a cost-effective alternative for manufacturers seeking intermediate yarn, balancing quality and affordability.

Choosing the Right Yarn for Your Textile Needs

Choosing the right yarn between Full Drawn Yarn (FDY) and Partially Oriented Yarn (POY) depends on the end-use and fabric properties desired. FDY offers superior strength, smoothness, and uniformity, making it ideal for high-quality woven and knitted fabrics requiring durability and a polished finish. POY, being semi-processed, is more flexible for downstream processes like texturizing and is suitable for fabrics needing elasticity and varied textures, influencing cost-efficiency and fabric performance.

Full Drawn Yarn vs Partially Oriented Yarn Infographic

libmatt.com

libmatt.com