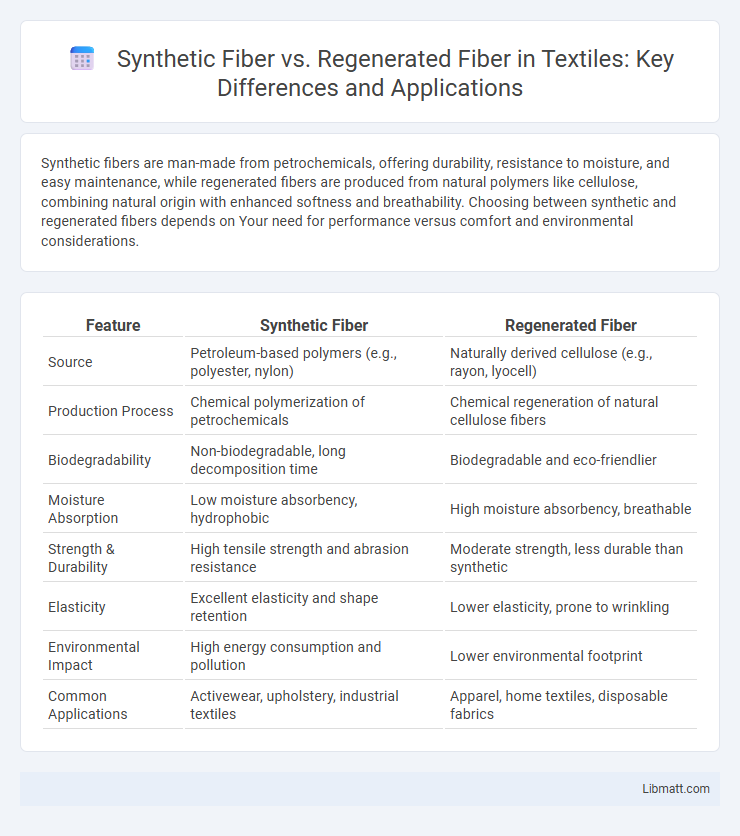

Synthetic fibers are man-made from petrochemicals, offering durability, resistance to moisture, and easy maintenance, while regenerated fibers are produced from natural polymers like cellulose, combining natural origin with enhanced softness and breathability. Choosing between synthetic and regenerated fibers depends on Your need for performance versus comfort and environmental considerations.

Table of Comparison

| Feature | Synthetic Fiber | Regenerated Fiber |

|---|---|---|

| Source | Petroleum-based polymers (e.g., polyester, nylon) | Naturally derived cellulose (e.g., rayon, lyocell) |

| Production Process | Chemical polymerization of petrochemicals | Chemical regeneration of natural cellulose fibers |

| Biodegradability | Non-biodegradable, long decomposition time | Biodegradable and eco-friendlier |

| Moisture Absorption | Low moisture absorbency, hydrophobic | High moisture absorbency, breathable |

| Strength & Durability | High tensile strength and abrasion resistance | Moderate strength, less durable than synthetic |

| Elasticity | Excellent elasticity and shape retention | Lower elasticity, prone to wrinkling |

| Environmental Impact | High energy consumption and pollution | Lower environmental footprint |

| Common Applications | Activewear, upholstery, industrial textiles | Apparel, home textiles, disposable fabrics |

Introduction to Synthetic and Regenerated Fibers

Synthetic fibers, such as polyester and nylon, are man-made fibers produced through chemical processes using petrochemical substances, offering high durability and resistance to moisture. Regenerated fibers, including rayon and lyocell, are created by chemically treating natural cellulose from wood pulp or cotton linters, combining natural origin with enhanced fiber properties. Both fiber types serve diverse textile applications by balancing strength, comfort, and sustainability considerations.

Definition and Origin of Synthetic Fibers

Synthetic fibers are man-made fibers produced through chemical synthesis, primarily derived from petrochemicals such as petroleum and natural gas. These fibers, including polyester, nylon, and acrylic, are created by polymerizing monomers into long-chain polymers through processes like extrusion and spinning. Unlike regenerated fibers, which come from natural cellulose sources chemically processed into fiber form, synthetic fibers are entirely engineered from non-renewable resources in controlled industrial environments.

Definition and Origin of Regenerated Fibers

Regenerated fibers are manufactured fibers created by chemically processing natural polymers such as cellulose from wood pulp or cotton linters, transforming them into man-made fibers like viscose, modal, and lyocell. Unlike synthetic fibers, which are made from petrochemical sources through polymerization, regenerated fibers retain the natural polymer structure but undergo regeneration to convert raw materials into textile fibers. Understanding the origin of regenerated fibers helps you appreciate their unique blend of natural and synthetic properties, offering breathability and comfort similar to natural fibers while benefiting from enhanced durability and versatility.

Key Differences Between Synthetic and Regenerated Fibers

Synthetic fibers, such as polyester and nylon, are entirely man-made from petrochemical sources, offering high durability, resistance to moisture, and easy maintenance. Regenerated fibers, like rayon and viscose, are derived from natural cellulose treated chemically to form fibers, providing better breathability and a softer texture compared to synthetic counterparts. Understanding these distinctions helps you select materials based on performance needs, comfort, and environmental impact.

Manufacturing Processes of Synthetic Fibers

Synthetic fibers are manufactured through chemical processes that involve polymerization of petrochemicals, creating fibers like polyester, nylon, and acrylic. These fibers are extruded through spinnerets in a process called melt spinning or solution spinning, producing continuous filament fibers with consistent strength and durability. Understanding these manufacturing techniques can help you appreciate the advanced technology and control behind synthetic fibers compared to regenerated fibers, which derive from natural cellulose through chemical modification.

Production Techniques for Regenerated Fibers

Regenerated fibers are produced through chemical processes that convert natural polymers like cellulose into continuous filaments, primarily using methods such as viscose, lyocell, and cupro techniques. The viscose process involves dissolving cellulose in alkali and carbon disulfide to create a viscous solution, which is then extruded into fiber form. Lyocell production uses a solvent-spinning method with non-toxic N-methylmorpholine N-oxide, resulting in fibers with superior strength and environmental benefits compared to traditional viscose.

Physical and Chemical Properties Comparison

Synthetic fibers, such as polyester and nylon, are derived from petrochemicals and exhibit high tensile strength, excellent abrasion resistance, and hydrophobic properties, making them less absorbent but quick-drying. Regenerated fibers like rayon and lyocell are produced from natural cellulose treated chemically, offering greater moisture absorbency, a softer texture, and better breathability but lower durability and resistance to heat and chemicals compared to synthetic fibers. Your choice between these materials depends on the desired balance of durability versus comfort and environmental impact.

Environmental Impact: Synthetic vs Regenerated Fibers

Synthetic fibers, such as polyester and nylon, are derived from petrochemicals and contribute significantly to environmental pollution due to non-biodegradability and microplastic release. Regenerated fibers like rayon and lyocell are produced from natural cellulose sources, offering better biodegradability and lower carbon footprints, although their chemical processing can involve harmful substances. Your choice between synthetic and regenerated fibers can influence environmental sustainability, emphasizing the importance of considering biodegradability, resource consumption, and pollution levels.

Applications and Uses in the Textile Industry

Synthetic fibers such as polyester, nylon, and acrylic dominate the textile industry due to their durability, moisture resistance, and elasticity, making them ideal for activewear, outdoor fabrics, and upholstery. Regenerated fibers like viscose, modal, and lyocell offer breathability and a softer hand feel, commonly used in apparel, home textiles, and disposable hygiene products to enhance comfort and sustainability. Both fiber types complement each other by balancing performance and environmental considerations across diverse textile applications.

Future Trends and Innovations in Fiber Technology

Advancements in fiber technology are driving the development of synthetic fibers with enhanced sustainability, such as bio-based polymers and biodegradable options, addressing environmental concerns. Regenerated fibers are evolving through innovative processes like solvent spinning and closed-loop recycling, improving resource efficiency and reducing chemical impact. Your choice between synthetic and regenerated fibers will increasingly depend on emerging eco-friendly innovations and performance enhancements tailored to specific applications.

Synthetic fiber vs Regenerated fiber Infographic

libmatt.com

libmatt.com