Calendering produces a smooth, glossy finish by pressing fabric between rollers, enhancing texture and sheen ideal for materials like leather or synthetic textiles. Brushing raises the fabric's surface fibers, creating a soft, fuzzy texture that improves warmth and comfort, making it perfect for garments like sweaters and blankets.

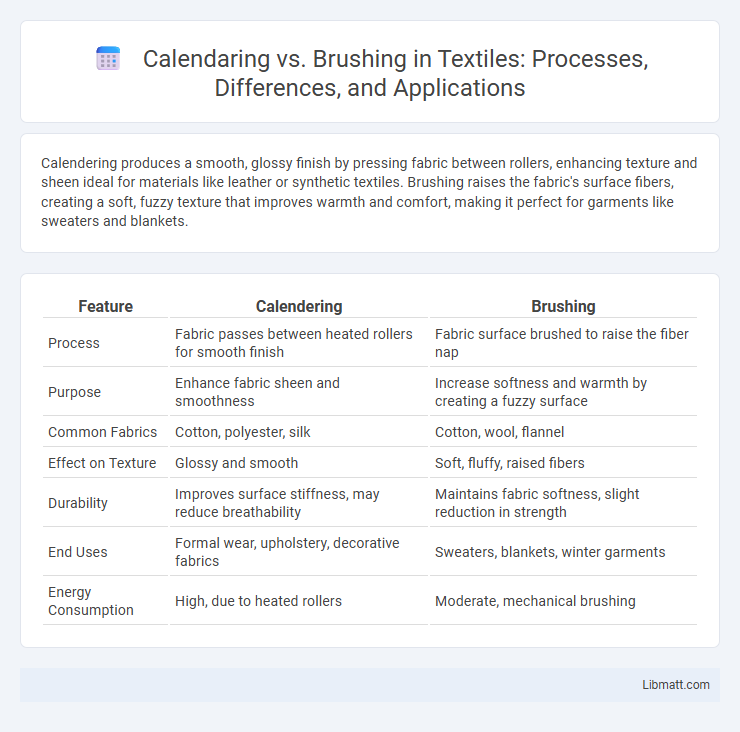

Table of Comparison

| Feature | Calendering | Brushing |

|---|---|---|

| Process | Fabric passes between heated rollers for smooth finish | Fabric surface brushed to raise the fiber nap |

| Purpose | Enhance fabric sheen and smoothness | Increase softness and warmth by creating a fuzzy surface |

| Common Fabrics | Cotton, polyester, silk | Cotton, wool, flannel |

| Effect on Texture | Glossy and smooth | Soft, fluffy, raised fibers |

| Durability | Improves surface stiffness, may reduce breathability | Maintains fabric softness, slight reduction in strength |

| End Uses | Formal wear, upholstery, decorative fabrics | Sweaters, blankets, winter garments |

| Energy Consumption | High, due to heated rollers | Moderate, mechanical brushing |

Introduction to Calendering and Brushing

Calendering and brushing are key fabric finishing techniques that enhance textile texture and appearance. Calendering involves passing fabric through heated rollers to create a smooth, glossy surface, improving its luster and firmness. Brushing raises fabric fibers to generate a soft, fuzzy feel, increasing warmth and comfort for your garments.

Understanding Calendering: Process and Applications

Calendering is a manufacturing process where materials like paper, fabric, or plastics are passed through a series of heated rollers to achieve a smooth, glossy, or uniform surface finish. This technique improves material density, enhances surface properties, and is widely used in industries such as textiles, packaging, and printing. Understanding calendering enables you to select the right surface treatment that optimizes quality and performance for your specific material application.

Brushing Explained: Methods and Uses

Brushing involves mechanically abrading fabric surfaces using wire brushes to create a soft, raised nap that enhances texture and warmth. Common methods include carding and napping, which lift fibers for improved insulation and aesthetic appeal in textiles such as flannel and fleece. This technique is widely used in fashion and home textiles to increase comfort and visual depth.

Key Differences Between Calendering and Brushing

Calendering involves pressing fabric or paper between rollers to achieve a smooth, glossy finish, enhancing surface uniformity and thickness control, while brushing uses wire brushes to raise the fibers, creating a soft, fuzzy texture that improves insulation and aesthetic appeal. Calendering typically results in a shiny, sleek look ideal for formal textiles and coated papers, whereas brushing produces a matte surface favored in casual apparel and upholstery for added warmth and comfort. Your choice depends on the desired texture and function, balancing smoothness from calendering against the cozy feel imparted by brushing.

Equipment and Technology Involved

Calendarizing utilizes large rollers and heavy-duty tension systems to smooth and compress materials such as fabrics, paper, and plastics, employing high-precision temperature controls and variable roller pressures for consistent surface finish. Brushing involves specialized rotating brushes or abrasive belts designed to raise fibers and create a textured, soft surface on textiles, often integrated with conveyor systems for continuous processing and timing controls to ensure uniform nap formation. Advanced equipment in calendaring focuses on temperature-regulated steel rollers and hydraulic systems, whereas brushing technology leverages motorized brush assemblies with adjustable speed and pressure settings to tailor fabric hand feel and appearance.

Material Suitability for Each Technique

Calendering is best suited for synthetic fabrics like polyester and nylon, as it enhances smoothness and imparts a glossy finish without compromising fabric strength. Brushing is ideal for natural fibers such as cotton and wool, effectively raising the nap to create a soft, warm texture perfect for flannel and fleece materials. Each technique optimizes the surface properties of specific materials to enhance their tactile and visual appeal.

Surface Finish and Texture Comparison

Calendering produces a smooth, glossy surface finish by passing materials through rollers that compress and flatten the texture, resulting in uniform sheen and reduced surface roughness. Brushing creates a textured surface finish with fine scratches or grain patterns, enhancing grip and reducing reflectivity by mechanically altering the material's top layer. Your choice between calendering and brushing depends on whether you prioritize a sleek, polished appearance or a tactile, non-slip surface texture.

Performance and Durability Outcomes

Calendering produces a smooth, glossy surface by compressing fibers, enhancing fabric density and durability, but may reduce breathability and flexibility. Brushing raises the fabric's surface fibers, creating a soft, textured feel with improved insulation and comfort, while slightly compromising long-term wear resistance. Performance outcomes show calendered fabrics excel in strength and moisture resistance, whereas brushed fabrics prioritize softness and warmth retention.

Industry-Specific Preferences

Calendering is preferred in the textile and paper industries for producing smooth, glossy surfaces by passing materials through heated rollers, enhancing fabric finish and paper quality. Brushing is commonly utilized in the apparel and upholstery sectors to create soft, raised textures on fabrics, improving comfort and aesthetic appeal. Industry-specific applications depend on desired surface characteristics, with calendering favored for sleek finishes and brushing chosen for tactile warmth and softness.

Choosing the Right Method: Factors to Consider

Choosing between calendering and brushing depends on the desired fabric finish, texture, and durability requirements. Calendering is ideal for achieving a smooth, glossy surface by applying pressure and heat, while brushing enhances softness and warmth by lifting fibers. Consider the end-use application, fabric type, and maintenance needs to select the most suitable method for optimal performance and visual appeal.

Calendering vs Brushing Infographic

libmatt.com

libmatt.com