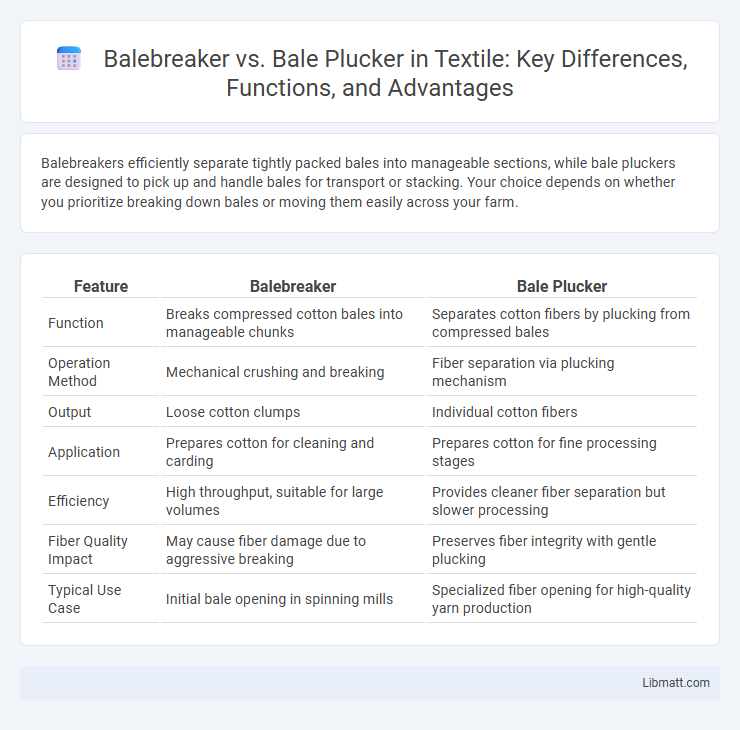

Balebreakers efficiently separate tightly packed bales into manageable sections, while bale pluckers are designed to pick up and handle bales for transport or stacking. Your choice depends on whether you prioritize breaking down bales or moving them easily across your farm.

Table of Comparison

| Feature | Balebreaker | Bale Plucker |

|---|---|---|

| Function | Breaks compressed cotton bales into manageable chunks | Separates cotton fibers by plucking from compressed bales |

| Operation Method | Mechanical crushing and breaking | Fiber separation via plucking mechanism |

| Output | Loose cotton clumps | Individual cotton fibers |

| Application | Prepares cotton for cleaning and carding | Prepares cotton for fine processing stages |

| Efficiency | High throughput, suitable for large volumes | Provides cleaner fiber separation but slower processing |

| Fiber Quality Impact | May cause fiber damage due to aggressive breaking | Preserves fiber integrity with gentle plucking |

| Typical Use Case | Initial bale opening in spinning mills | Specialized fiber opening for high-quality yarn production |

Introduction to Balebreakers and Bale Pluckers

Balebreakers and bale pluckers are essential agricultural machines designed for efficient hay handling and livestock feed preparation. Balebreakers break large hay bales into smaller, manageable pieces to improve feed accessibility and reduce waste during distribution. Bale pluckers extract loose hay directly from the bale's surface, offering a precise and controlled feeding method that minimizes spoilage and maximizes feed quality.

Key Differences Between Balebreakers and Bale Pluckers

Balebreakers and bale pluckers serve distinct roles in agricultural bale processing; balebreakers are designed to break down compacted bales into manageable pieces, enhancing feedability and reducing waste, while bale pluckers efficiently remove individual bales from stacks or storage areas for transportation or feeding. The primary difference lies in their function--balebreakers focus on breaking and loosening, whereas bale pluckers specialize in lifting and transporting bales intact. Understanding these key differences helps you select the appropriate equipment to optimize your bale handling and feed management operations.

How Balebreakers Work: A Detailed Overview

Balebreakers operate by using high-impact jaws that crush and fragment large bales of materials like cardboard, plastic, or paper, significantly reducing their volume for easier handling and transport. These machines employ hydraulic systems that deliver powerful, controlled pressure to break apart dense, compacted bales, enhancing recycling efficiency and minimizing storage space. Understanding how Balebreakers work can help you optimize your material processing workflow and improve overall operational productivity.

Bale Plucker Mechanism and Functionality

The Bale Plucker mechanism is specifically designed to efficiently grab and detach individual bales from stacks or piles using hydraulic claws or gripping arms, ensuring minimal damage to the bale structure. Its functionality revolves around precise control and strong gripping force, allowing operators to seamlessly handle various bale sizes and types, including straw, hay, and silage. You'll find the Bale Plucker excels in improving loading and unloading efficiency compared to the more general-purpose Balebreaker, which is intended mainly for breaking down straw bales.

Advantages of Using a Balebreaker

Using a balebreaker significantly improves operational efficiency by quickly and safely breaking down large cotton or hay bales into manageable pieces, reducing manual labor and injury risks. This equipment enhances productivity with consistent bale processing speeds, minimizing downtime compared to traditional bale pluckers. Moreover, balebreakers provide more uniform bale disintegration, ensuring better material flow for subsequent handling or processing stages.

Benefits of Implementing a Bale Plucker in Textile Processing

Implementing a bale plucker in textile processing significantly enhances fiber quality by gently separating fibers without excessive damage, improving overall yarn strength and consistency. It increases operational efficiency by reducing manual labor and processing time compared to traditional bale breakers, leading to faster throughput and cost savings. The bale plucker's precise fiber opening capabilities minimize contamination and ensure uniform fiber distribution, crucial for high-quality textile production.

Efficiency Comparison: Balebreaker vs Bale Plucker

Balebreakers deliver higher efficiency by automating the bale opening process, significantly reducing manual labor compared to bale pluckers, which rely on manual or semi-automated extraction methods. Your productivity increases as balebreakers handle larger volumes faster, minimizing downtime and material handling errors. Bale pluckers, while cost-effective for smaller operations, lag behind in throughput and consistency when measured against the continuous workflow capabilities of balebreakers.

Applications in the Textile Industry

Balebreakers efficiently separate compressed cotton bales into loose fibers, facilitating smooth feeding into spinning machinery, while bale pluckers are designed to pull out raw cotton from bales without fully breaking them down, preserving fiber integrity for further processing. In the textile industry, balebreakers are essential for large-scale cotton processing where fiber separation and uniformity impact yarn quality and production speed. Bale pluckers are preferred in applications requiring gentle fiber handling to maintain staple length, crucial for high-quality textile products like fine yarns and delicate fabrics.

Factors to Consider When Choosing Between Balebreaker and Bale Plucker

When choosing between a balebreaker and a bale plucker, consider the type and size of bales you handle, as balebreakers excel at breaking dense, large bales while bale pluckers efficiently extract layers from smaller or compressed bales. Assessing the speed and precision required for your operations can impact efficiency, where bale pluckers offer controlled bale layer removal and balebreakers provide rapid bale disintegration. Your farm's specific crop residue management needs, machinery compatibility, and budget constraints play a crucial role in determining the right equipment to optimize productivity and maintain bale quality.

Future Trends and Technological Advances in Bale Opening Equipment

The future of bale opening equipment like Balebreaker and Bale plucker is driven by automation and precision technology, enhancing efficiency and reducing labor costs in textile recycling. Advanced sensors and AI integration enable real-time monitoring and optimization, improving fiber quality and throughput. Sustainable design innovations focus on energy-efficient motors and modular components to support circular economy goals in the textile industry.

Balebreaker vs Bale plucker Infographic

libmatt.com

libmatt.com