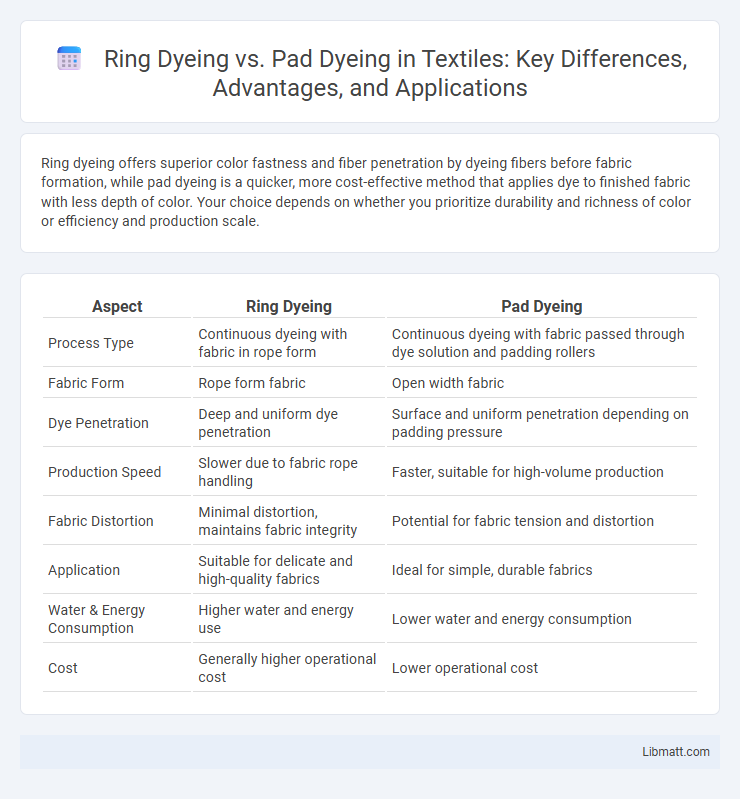

Ring dyeing offers superior color fastness and fiber penetration by dyeing fibers before fabric formation, while pad dyeing is a quicker, more cost-effective method that applies dye to finished fabric with less depth of color. Your choice depends on whether you prioritize durability and richness of color or efficiency and production scale.

Table of Comparison

| Aspect | Ring Dyeing | Pad Dyeing |

|---|---|---|

| Process Type | Continuous dyeing with fabric in rope form | Continuous dyeing with fabric passed through dye solution and padding rollers |

| Fabric Form | Rope form fabric | Open width fabric |

| Dye Penetration | Deep and uniform dye penetration | Surface and uniform penetration depending on padding pressure |

| Production Speed | Slower due to fabric rope handling | Faster, suitable for high-volume production |

| Fabric Distortion | Minimal distortion, maintains fabric integrity | Potential for fabric tension and distortion |

| Application | Suitable for delicate and high-quality fabrics | Ideal for simple, durable fabrics |

| Water & Energy Consumption | Higher water and energy use | Lower water and energy consumption |

| Cost | Generally higher operational cost | Lower operational cost |

Introduction to Ring Dyeing and Pad Dyeing

Ring dyeing involves the fiber yarn being dyed in continuous loops within a closed ring system, ensuring uniform color absorption and vibrant hues. Pad dyeing, on the other hand, utilizes a series of rollers to impregnate the fabric with dye, allowing for precise color control and efficient processing of large fabric volumes. Your choice between ring dyeing and pad dyeing depends on factors like fabric type, production speed, and color consistency requirements.

Historical Background and Evolution

Ring dyeing originated in the early 20th century as a solution for uniform coloration of synthetic fibers, evolving through technological advancements to improve dye uptake and reduce water consumption. Pad dyeing, developed earlier in the late 19th century, became prominent due to its versatility and efficiency in treating various fabric types, adapting over decades with innovations such as continuous padding machines and eco-friendly dyeing agents. Both methods have significantly shaped textile finishing processes by balancing quality, cost, and environmental impact in industrial applications.

Key Processes: Ring Dyeing Explained

Ring dyeing involves immersing yarns in dye liquor within perforated cones arranged on a rotating ring, ensuring uniform color absorption through continuous movement and exposure. This process allows for deep penetration of dye into the yarn fibers, resulting in rich, consistent shades ideal for high-quality textiles. Your choice between ring dyeing and pad dyeing depends on fabric type and desired colorfastness, with ring dyeing offering superior durability and vibrancy.

Key Processes: Pad Dyeing Explained

Pad dyeing involves passing fabric through a dye solution followed by squeezing it between rollers to ensure uniform dye distribution and penetration. This continuous process is efficient for applying dyes evenly on woven or knitted fabrics, making it ideal for large-scale textile production. Your choice of pad dyeing can enhance color consistency and reduce water usage compared to other methods like ring dyeing.

Machinery Used in Each Dyeing Method

Ring dyeing utilizes ring dyeing machines, characterized by vertically rotating yarn packages and multiple dye zones for precise color application. Pad dyeing employs padding mangle machines, which consist of rollers that squeeze fabric through dye baths and then through padding rollers for uniform dyeing on continuous fabric lengths. Your choice of machinery affects dye penetration, production speed, and fabric handling efficiency depending on the textile type.

Differences in Dye Penetration and Color Uniformity

Ring dyeing achieves superior dye penetration by immersing yarn rings directly into dye baths, resulting in deeper color absorption and more vibrant hues. Pad dyeing, on the other hand, applies dye by pressing fabric through dye liquor, often leading to surface-level dyeing with less penetration and potential color inconsistency. Consequently, ring dyeing offers greater color uniformity and durability, while pad dyeing may exhibit uneven shades due to limited dye diffusion.

Impact on Fabric Strength and Texture

Ring dyeing enhances fabric strength by evenly embedding dye molecules within yarn fibers, preserving the textile's original tensile properties. Pad dyeing may weaken fabric as the dyeing process involves pressure rollers that can cause fiber distortion and affect fabric hand feel. Textures from ring dyeing often appear smoother with uniform color penetration, while pad dyeing can produce varied surface textures due to dye application techniques.

Environmental Considerations and Sustainability

Ring dyeing typically consumes more water and energy than pad dyeing, leading to a higher environmental footprint. Pad dyeing uses less water and fewer chemicals, making it a more sustainable option in textile processing. The reduced resource consumption in pad dyeing supports eco-friendly practices and lowers wastewater pollution.

Cost Implications and Production Efficiency

Ring dyeing generally incurs higher costs due to slower processing times and increased water and energy consumption compared to pad dyeing, which operates at faster speeds and uses less water. Pad dyeing offers better production efficiency with continuous fabric processing and quicker turnaround, making it ideal for mass production settings. While ring dyeing provides superior dye penetration and color uniformity for premium textiles, pad dyeing's cost-effectiveness and high throughput remain advantageous for large-scale manufacturing.

Choosing the Right Dyeing Method for Your Textile Needs

Ring dyeing offers superior colorfastness and depth by dyeing fibers before yarn formation, ideal for high-quality textiles with vibrant patterns. Pad dyeing applies dye to woven or knitted fabrics through padding rollers, providing efficient, uniform color for large-scale production and lighter shades. Your choice between ring and pad dyeing should align with desired fabric quality, color intensity, and production volume to optimize textile performance.

Ring Dyeing vs Pad Dyeing Infographic

libmatt.com

libmatt.com