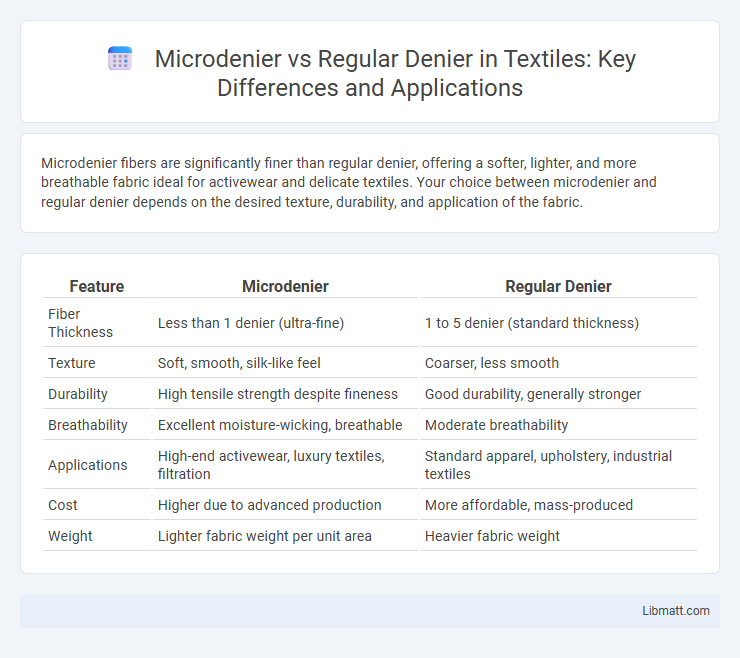

Microdenier fibers are significantly finer than regular denier, offering a softer, lighter, and more breathable fabric ideal for activewear and delicate textiles. Your choice between microdenier and regular denier depends on the desired texture, durability, and application of the fabric.

Table of Comparison

| Feature | Microdenier | Regular Denier |

|---|---|---|

| Fiber Thickness | Less than 1 denier (ultra-fine) | 1 to 5 denier (standard thickness) |

| Texture | Soft, smooth, silk-like feel | Coarser, less smooth |

| Durability | High tensile strength despite fineness | Good durability, generally stronger |

| Breathability | Excellent moisture-wicking, breathable | Moderate breathability |

| Applications | High-end activewear, luxury textiles, filtration | Standard apparel, upholstery, industrial textiles |

| Cost | Higher due to advanced production | More affordable, mass-produced |

| Weight | Lighter fabric weight per unit area | Heavier fabric weight |

Introduction to Denier: Understanding Fiber Thickness

Denier measures fiber thickness, representing the weight in grams of 9,000 meters of a fiber strand; microdenier fibers are finer, typically less than 1 denier, compared to regular denier fibers ranging from 1 to 3 denier or higher. Microdenier fibers create softer, more lightweight, and more breathable fabrics, ideal for performance wear and luxury textiles. Regular denier fibers provide greater durability and structure, making them suitable for everyday apparel and home textiles.

What is Microdenier? Defining the Finer Fiber

Microdenier refers to fibers that are finer than the standard denier measurement, typically measuring less than 1 denier per filament, which enhances softness and drape. These ultra-fine fibers create fabrics with a lightweight feel, improved breathability, and superior moisture-wicking properties compared to regular denier fibers. Choosing microdenier materials in your textiles results in a smoother texture and increased comfort, making them ideal for performance apparel and luxury fabrics.

Regular Denier Explained: Standard Fiber Sizing

Regular denier refers to the standard measurement unit for the linear mass density of fibers, defined as the grams per 9,000 meters of yarn. Typically ranging from 30 to 300 denier, regular denier fibers are thicker and provide enhanced durability and strength compared to microdenier fibers. This standard sizing is commonly used in textiles requiring robustness, such as upholstery, outerwear, and heavy-duty fabrics.

Key Differences Between Microdenier and Regular Denier

Microdenier fibers measure less than one denier, offering finer, softer, and more lightweight fabric compared to regular denier fibers, which typically range from 1 to 5 denier or higher. The increased surface area and smaller diameter of microdenier improve moisture-wicking, breathability, and durability, making microdenier ideal for activewear and high-performance textiles. Your choice between microdenier and regular denier should consider fabric texture, weight, and intended use for optimal comfort and functionality.

Performance and Durability: Microdenier vs Regular Denier

Microdenier fabrics offer superior softness and lightweight performance compared to regular denier, enhancing comfort without sacrificing strength. Regular denier materials typically provide greater durability and abrasion resistance, making them ideal for heavy-duty applications. The choice between microdenier and regular denier depends on balancing the need for fine texture with long-lasting toughness in specific use cases.

Comfort and Feel: How Fiber Size Impacts Textiles

Microdenier fibers, significantly finer than regular denier fibers, create textiles with superior softness and a lightweight feel, enhancing overall comfort. The smaller diameter allows for a silkier texture and improved breathability, making fabrics more pleasant against Your skin. In contrast, regular denier fibers result in a coarser, heavier fabric that may lack the delicate touch and moisture-wicking properties found in microdenier textiles.

Common Applications of Microdenier Fabrics

Microdenier fabrics, characterized by fibers thinner than 1 denier, are commonly used in high-performance activewear, microfiber cleaning cloths, and luxury bedding due to their softness, breathability, and moisture-wicking properties. These ultra-fine fibers enable superior filtration and enhanced durability in automotive and medical textiles, setting microdenier apart from regular denier fabrics that typically feature thicker fibers for more robust, everyday apparel and upholstery. The fine structure of microdenier yarns allows for exceptional drape and comfort, making them ideal for intimate apparel and lightweight outdoor gear.

Uses and Benefits of Regular Denier Materials

Regular denier materials provide exceptional durability and strength, making them ideal for heavy-duty applications like backpacks, upholstery, and outdoor gear. These fabrics offer excellent resistance to abrasion, tearing, and wear, ensuring long-lasting performance in demanding environments. Your choice of regular denier materials supports robust construction and reliable protection for everyday and industrial use.

Environmental Impact: Sustainability Considerations

Microdenier fibers, typically thinner than 1 denier, often require more energy-intensive manufacturing processes compared to regular denier fibers, resulting in a higher carbon footprint. Regular denier fabrics, being thicker, tend to have longer durability and may generate less waste over time, supporting sustainability efforts. Choosing microdenier materials with recycled content or biodegradable properties can mitigate environmental impacts and promote sustainable textile production.

Choosing the Right Denier for Your Needs

Microdenier fabrics, characterized by fibers finer than one denier, provide superior softness, lightweight comfort, and enhanced breathability compared to regular denier materials. Choosing the right denier depends on your specific needs: microdenier suits applications requiring delicate texture and moisture-wicking properties, while regular denier offers greater durability and strength for heavy-duty use. Understanding your usage environment helps you select the ideal balance between comfort and durability for optimal performance.

Microdenier vs Regular denier Infographic

libmatt.com

libmatt.com