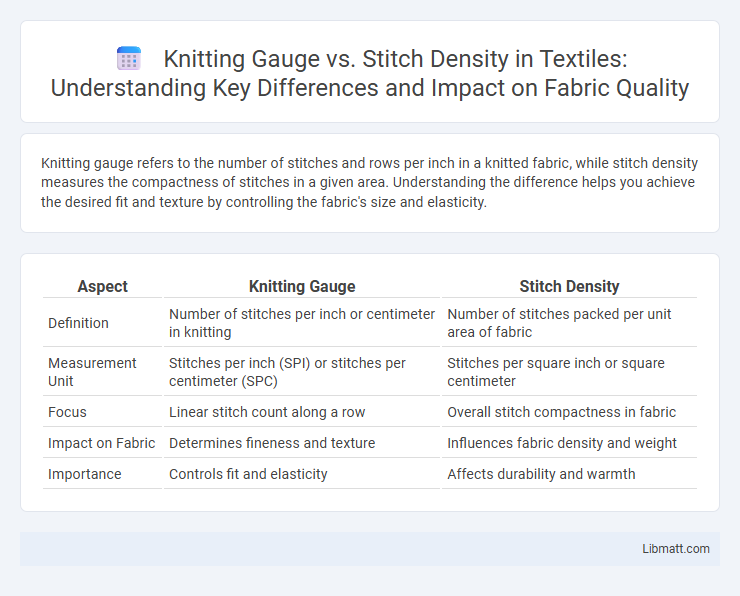

Knitting gauge refers to the number of stitches and rows per inch in a knitted fabric, while stitch density measures the compactness of stitches in a given area. Understanding the difference helps you achieve the desired fit and texture by controlling the fabric's size and elasticity.

Table of Comparison

| Aspect | Knitting Gauge | Stitch Density |

|---|---|---|

| Definition | Number of stitches per inch or centimeter in knitting | Number of stitches packed per unit area of fabric |

| Measurement Unit | Stitches per inch (SPI) or stitches per centimeter (SPC) | Stitches per square inch or square centimeter |

| Focus | Linear stitch count along a row | Overall stitch compactness in fabric |

| Impact on Fabric | Determines fineness and texture | Influences fabric density and weight |

| Importance | Controls fit and elasticity | Affects durability and warmth |

Understanding Knitting Gauge

Knitting gauge measures the number of stitches and rows per inch in a knitted fabric, crucial for achieving accurate sizing. Stitch density refers to how tightly or loosely the yarn is packed within the stitches, affecting the fabric's texture and elasticity. Understanding knitting gauge helps knitters select the right needle size and tension to match the pattern's intended stitch density, ensuring a proper fit and consistent fabric quality.

What Is Stitch Density?

Stitch density refers to the number of stitches packed within a specific area of fabric, directly influencing the texture, stretch, and durability of a knitted piece. Unlike gauge, which measures stitches per inch or centimeter in rows and columns, stitch density accounts for how tightly or loosely those stitches are packed together, impacting the overall fabric quality. Understanding stitch density helps you control the thickness and feel of your knitted projects for precise results.

Key Differences Between Gauge and Stitch Density

Knitting gauge measures the number of stitches and rows per inch in a knitted fabric, directly influencing the garment's size and fit. Stitch density refers to how tightly or loosely stitches are packed within the fabric, affecting texture, elasticity, and drape. Gauge primarily impacts pattern sizing, while stitch density determines the fabric's structural and aesthetic qualities.

Why Gauge Matters in Knitting Projects

Knitting gauge determines the number of stitches and rows per inch, directly impacting stitch density and the final size of the project. Accurate gauge ensures garments fit as intended and maintain the desired texture and drape by matching the pattern specifications. Ignoring gauge can result in oversized or undersized pieces, affecting both aesthetics and wearability in knitting projects.

Measuring Stitch Density Accurately

Measuring stitch density accurately involves counting the number of stitches and rows within a specified area, typically a 4x4 inch swatch, to determine the exact stitch concentration per square inch. Knitting gauge focuses on the number of stitches per inch in both horizontal and vertical directions, while stitch density accounts for the compactness and distribution of stitches within the fabric, impacting texture and elasticity. Precise measurement requires blocking the swatch to stabilize the fabric before counting to avoid discrepancies caused by yarn stretch or tension variations.

Tools Needed for Gauge and Density Checks

Accurate knitting gauge and stitch density assessments require essential tools like a ruler or gauge swatch, knitting needles, and a stitch marker. A knitting gauge tool measures the number of stitches and rows per inch, while a stitch density gauge evaluates how tightly stitches are knitted, influencing fabric texture and elasticity. Using these specialized instruments ensures precision in pattern execution and garment fit.

Common Mistakes with Gauge and Density

Knitting gauge and stitch density are often confused, leading to common mistakes such as miscalculating the final size of a project or uneven fabric tension. A frequent error is failing to swatch properly, resulting in discrepancies between the intended gauge and actual stitch density, which affects fit and texture. Ensuring your gauge matches the pattern's specified stitch density is crucial for accuracy and to avoid wasting yarn or time.

How Yarn and Needle Choice Affect Both

Yarn weight and needle size directly impact your knitting gauge and stitch density by altering the size and tightness of each stitch. Thicker yarns combined with larger needles create a looser gauge and lower stitch density, while finer yarns and smaller needles produce a tighter gauge and higher stitch density. Understanding how these choices affect your project ensures accurate measurements and desired texture in your finished piece.

Adjusting Patterns for Preferred Density

Adjusting knitting patterns for your preferred stitch density requires understanding the difference between gauge and stitch density, as gauge measures stitches per inch while stitch density accounts for both stitches and rows in a defined area. Modifying needle size or yarn weight can help achieve the desired stitch density, ensuring your project maintains the correct dimensions and fabric texture. Accurate adjustments guarantee that your finished piece fits as intended and matches the original pattern's shaping and drape.

Tips for Consistent Knitting Results

Maintaining consistent knitting gauge and stitch density is crucial for achieving accurate garment dimensions and a professional finish. Use the same yarn, needles, and tension throughout your project, and always knit a gauge swatch before starting to check your stitch and row counts per inch. You can also block your swatch to match the intended fabric density, ensuring your final piece fits as expected.

Knitting gauge vs Stitch density Infographic

libmatt.com

libmatt.com