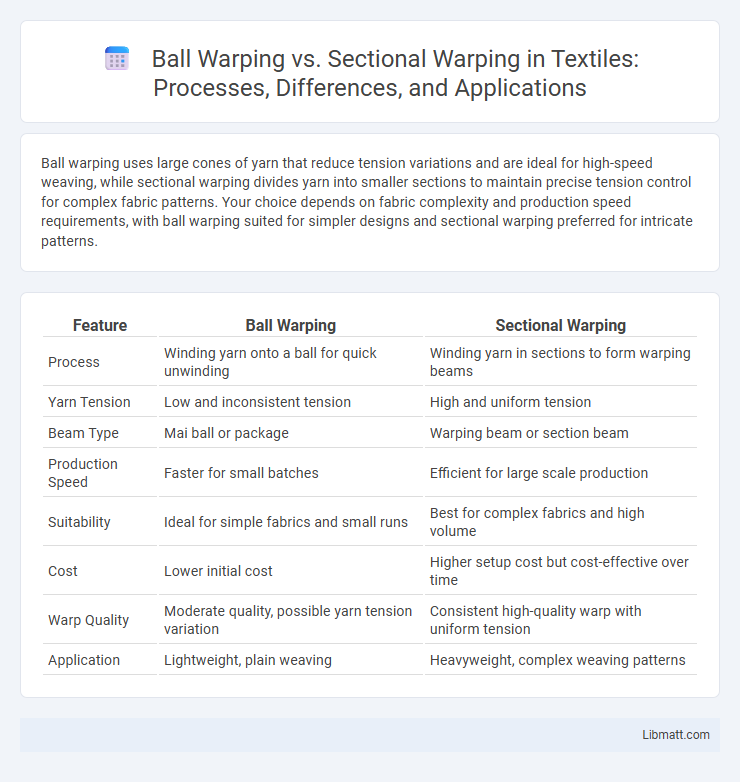

Ball warping uses large cones of yarn that reduce tension variations and are ideal for high-speed weaving, while sectional warping divides yarn into smaller sections to maintain precise tension control for complex fabric patterns. Your choice depends on fabric complexity and production speed requirements, with ball warping suited for simpler designs and sectional warping preferred for intricate patterns.

Table of Comparison

| Feature | Ball Warping | Sectional Warping |

|---|---|---|

| Process | Winding yarn onto a ball for quick unwinding | Winding yarn in sections to form warping beams |

| Yarn Tension | Low and inconsistent tension | High and uniform tension |

| Beam Type | Mai ball or package | Warping beam or section beam |

| Production Speed | Faster for small batches | Efficient for large scale production |

| Suitability | Ideal for simple fabrics and small runs | Best for complex fabrics and high volume |

| Cost | Lower initial cost | Higher setup cost but cost-effective over time |

| Warp Quality | Moderate quality, possible yarn tension variation | Consistent high-quality warp with uniform tension |

| Application | Lightweight, plain weaving | Heavyweight, complex weaving patterns |

Introduction to Ball Warping and Sectional Warping

Ball warping utilizes a spherical package to organize yarn efficiently, enabling continuous and automated warping processes that reduce downtime. Sectional warping involves winding yarn onto separate beams called sections, allowing precise control over tension and uniformity during fabric production. Both methods optimize warp preparation but cater to different production scales and fabric types, enhancing efficiency and fabric quality.

Overview of Warping Processes in Textile Manufacturing

Ball warping and sectional warping are essential fabric preparation techniques in textile manufacturing aimed at organizing yarns for weaving. Ball warping involves winding warp yarns from cones into a large, single ball, enabling smoother tension control, while sectional warping arranges yarns into smaller sections or chains, facilitating quicker yarn handling and changeover. Both processes optimize warp yarn alignment but differ in scale and flexibility, impacting weaving efficiency and fabric quality.

What is Ball Warping?

Ball warping is a textile process where yarn is wound onto a spherical package or "ball," facilitating high-speed weaving and uniform tension control. This method enhances fabric quality by reducing yarn entanglements and ensuring consistent tension, improving your weaving efficiency. Compared to sectional warping, ball warping offers smoother yarn feeding, particularly suited for fine or delicate yarns.

What is Sectional Warping?

Sectional warping is a textile warping process that divides the warp beam into smaller, manageable sections to improve tension control and fabric quality. This method enhances yarn alignment and reduces defects compared to the traditional ball warping technique, which uses a single large warp beam. Your fabric production can benefit from increased efficiency and precision by choosing sectional warping for complex or high-tension yarns.

Key Differences Between Ball Warping and Sectional Warping

Ball warping uses a single unwinding point with yarn delivered from multiple bobbins on a portable creel, enabling high-speed and continuous operation ideal for large production runs. Sectional warping involves arranging yarns on a stationary creel in sections that are combined and wound onto the warp beam sequentially, offering better control and tension uniformity suitable for varied fabric types. Your choice depends on production scale, fabric complexity, and precision requirements, with ball warping excelling in volume while sectional warping provides flexibility and consistency.

Advantages of Ball Warping

Ball warping offers significant advantages such as faster setup times and reduced labor costs compared to sectional warping. Its compact design enables efficient space utilization and simplifies the warping process by handling multiple yarn ends simultaneously. You benefit from enhanced productivity and consistent tension control, leading to improved fabric quality.

Advantages of Sectional Warping

Sectional warping offers precise control over yarn tension and alignment, reducing defects and enhancing fabric quality. This method allows simultaneous warping of multiple sections, increasing production efficiency and minimizing downtime. Your textile manufacturing benefits from improved consistency and faster turnaround compared to ball warping.

Applications of Ball and Sectional Warping

Ball warping is widely utilized in industries requiring high-speed yarn processing and uniform tension control, such as hosiery and seamless garment manufacturing. Sectional warping finds extensive application in producing heavy fabrics like denim and upholstery, where large beam sizes and precise sectional tensioning are critical. The choice between ball and sectional warping depends on fabric type, production volume, and the desired control over yarn alignment and tension uniformity.

Factors Influencing the Choice of Warping Method

Factors influencing the choice between ball warping and sectional warping include the type of fabric being produced, production volume, and machine compatibility. Ball warping suits smaller batches and lightweight fabrics, while sectional warping benefits large-scale operations and heavier or complex yarns. Your decision should also consider efficiency requirements, yarn tension control, and cost-effectiveness for optimal fabric quality.

Future Trends in Warping Technology

Future trends in warping technology emphasize automation and precision enhancement for both ball warping and sectional warping methods. Integration of AI-powered sensors and real-time monitoring systems is improving warp tension control and reducing fabric defects. Advanced materials and smart warping machines are expected to drive efficiency and sustainability in textile production.

Ball warping vs Sectional warping Infographic

libmatt.com

libmatt.com