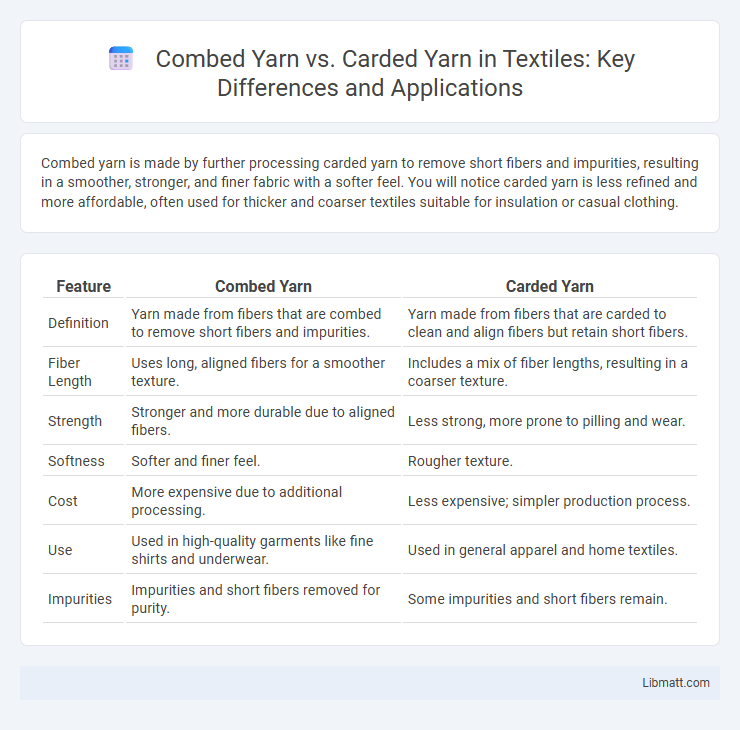

Combed yarn is made by further processing carded yarn to remove short fibers and impurities, resulting in a smoother, stronger, and finer fabric with a softer feel. You will notice carded yarn is less refined and more affordable, often used for thicker and coarser textiles suitable for insulation or casual clothing.

Table of Comparison

| Feature | Combed Yarn | Carded Yarn |

|---|---|---|

| Definition | Yarn made from fibers that are combed to remove short fibers and impurities. | Yarn made from fibers that are carded to clean and align fibers but retain short fibers. |

| Fiber Length | Uses long, aligned fibers for a smoother texture. | Includes a mix of fiber lengths, resulting in a coarser texture. |

| Strength | Stronger and more durable due to aligned fibers. | Less strong, more prone to pilling and wear. |

| Softness | Softer and finer feel. | Rougher texture. |

| Cost | More expensive due to additional processing. | Less expensive; simpler production process. |

| Use | Used in high-quality garments like fine shirts and underwear. | Used in general apparel and home textiles. |

| Impurities | Impurities and short fibers removed for purity. | Some impurities and short fibers remain. |

Introduction to Combed and Carded Yarn

Combed yarn undergoes an extra refining process that removes short fibers and impurities, resulting in stronger, smoother, and finer yarn compared to carded yarn, which is made by simply disentangling and cleaning fibers without removing short staples. This makes combed yarn ideal for high-quality textiles requiring durability and a soft finish, while carded yarn is more economical and suitable for bulkier, textured fabrics. Understanding the differences in processing helps you choose the right yarn type for your specific fabric needs and desired end-product quality.

Understanding the Yarn Manufacturing Process

Combed yarn undergoes an extra step in the manufacturing process where short fibers and impurities are removed, resulting in a smoother, stronger, and finer yarn compared to carded yarn, which is only roughly disentangled and cleaned. The combing process aligns fibers more uniformly, enhancing the yarn's durability and providing a luxurious finish, ideal for high-quality textile products. Understanding this difference helps You choose the right yarn for your fabric's desired texture, strength, and softness.

What is Carded Yarn?

Carded yarn is created by a carding process that cleans and detangles fibers, aligning them into a loose strand called a sliver. This yarn retains more impurities and shorter fibers compared to combed yarn, resulting in a coarser texture and less uniform appearance. Carded yarn is commonly used for products where durability and warmth are prioritized over softness and smoothness.

What is Combed Yarn?

Combed yarn is a type of cotton yarn that undergoes an extra process to remove short fibers and impurities, resulting in a smoother, stronger, and finer thread compared to carded yarn. This additional combing process aligns the fibers more uniformly, enhancing the yarn's durability and softness, making it ideal for high-quality textiles like fine clothing and luxury fabrics. Combed yarn typically produces fabrics with a cleaner finish and greater resistance to pilling and wear.

Key Differences between Combed and Carded Yarn

Combed yarn undergoes an extra process where short fibers and impurities are removed, resulting in a smoother, stronger, and finer yarn compared to carded yarn, which retains more fiber irregularities and has a coarser texture. The combing process aligns fibers parallel to each other, enhancing yarn uniformity, while carded yarn is produced by disentangling and cleaning fibers without removing shorter strands. These differences make combed yarn ideal for high-quality, lightweight textiles, whereas carded yarn is more suitable for thicker, durable fabrics.

Advantages of Combed Yarn

Combed yarn offers superior strength and smoothness compared to carded yarn due to the removal of short fibers and impurities during processing, resulting in higher durability and a softer texture. Its enhanced uniformity reduces pilling and increases fabric longevity, making it ideal for premium-quality garments and textiles. You benefit from improved comfort and a refined appearance in fabrics made with combed yarn.

Benefits of Carded Yarn

Carded yarn offers enhanced breathability and softer texture due to its less refined processing, making it ideal for comfortable, everyday fabrics. Its production preserves fiber length variability, which contributes to a more textured and durable fabric with excellent warmth retention. You benefit from carded yarn's affordability and natural feel, perfect for casual wear and home textiles.

Applications and Uses in Textiles

Combed yarn, characterized by its fine, smooth texture and minimal impurities, is ideal for high-quality textiles such as luxury apparel, fine knits, and premium shirting fabrics where softness and durability are essential. Carded yarn, with a coarser and more textured finish, suits applications in home textiles, denim, and casual wear, offering affordability and comfort but less refined appearance. The choice between combed and carded yarns impacts fabric strength, softness, and overall garment quality, influencing their specific use in textile production.

Cost Comparison: Combed vs Carded Yarn

Combed yarn generally costs more than carded yarn due to the additional processing that removes short fibers and impurities, resulting in a finer, stronger, and smoother yarn. Carded yarn production is less expensive because it involves a simpler process that leaves some short fibers intact, making it suitable for thicker, more textured fabrics. The higher price of combed yarn reflects its enhanced quality and durability, often preferred for premium textiles and garments.

Choosing the Right Yarn for Your Project

Combed yarn features a smoother, finer texture due to the removal of short fibers, making it ideal for high-quality garments requiring durability and softness. Carded yarn retains more fiber irregularities and offers a fluffier, warmer feel, suitable for casual wear and insulation. Selecting the right yarn depends on the desired fabric strength, finish, and end-use, with combed yarn favored for luxury projects and carded yarn preferred for cost-effective, comfortable textiles.

Combed yarn vs Carded yarn Infographic

libmatt.com

libmatt.com