Resin finish provides a durable, water-resistant coating that enhances the fabric's strength and wrinkle resistance, ideal for maintaining a polished look over time. Starch finish, on the other hand, offers a crisp, stiff texture that is easily refreshed with each wash but may wear off quickly, requiring frequent reapplication to keep Your garments looking sharp.

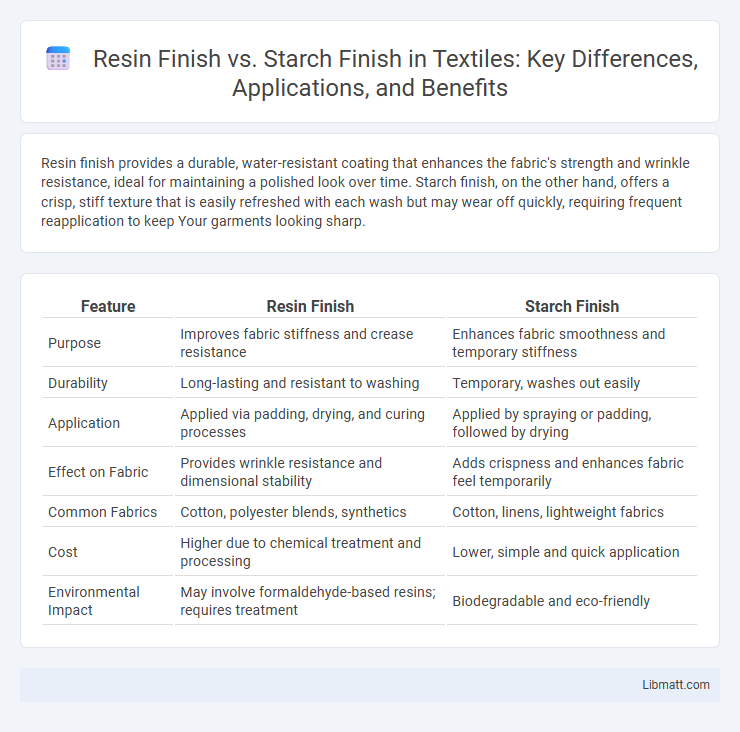

Table of Comparison

| Feature | Resin Finish | Starch Finish |

|---|---|---|

| Purpose | Improves fabric stiffness and crease resistance | Enhances fabric smoothness and temporary stiffness |

| Durability | Long-lasting and resistant to washing | Temporary, washes out easily |

| Application | Applied via padding, drying, and curing processes | Applied by spraying or padding, followed by drying |

| Effect on Fabric | Provides wrinkle resistance and dimensional stability | Adds crispness and enhances fabric feel temporarily |

| Common Fabrics | Cotton, polyester blends, synthetics | Cotton, linens, lightweight fabrics |

| Cost | Higher due to chemical treatment and processing | Lower, simple and quick application |

| Environmental Impact | May involve formaldehyde-based resins; requires treatment | Biodegradable and eco-friendly |

Overview of Resin Finish and Starch Finish

Resin finish involves applying synthetic polymers to fabrics, enhancing durability, wrinkle resistance, and water repellency by creating a protective layer on the textile surface. Starch finish, made from natural plant starches, provides a crisp, stiff texture that firms fabric fibers, primarily used for maintaining shape and adding stiffness to garments like shirts and uniforms. Your choice between resin and starch finishes depends on the desired fabric properties, such as long-lasting protection with resin or temporary stiffness with starch.

Composition and Application Methods

Resin finish consists of synthetic polymers such as acrylic, polyurethane, or epoxy resins, applied by spraying or brushing to enhance surface durability and water resistance. Starch finish, derived from natural plant starches like corn or potato, is typically applied as a liquid paste or spray to provide temporary stiffness and wrinkle resistance in textiles. Resin finishes create long-lasting, hard protective layers, whereas starch finishes offer biodegradable and easily washable coatings primarily used in fabric care.

Durability and Longevity Comparison

Resin finishes provide superior durability and longevity compared to starch finishes due to their water-resistant and protective coating that shields surfaces from wear and environmental damage. Starch finishes offer a more natural look but are less resistant to moisture and abrasion, resulting in shorter lifespan and frequent reapplications. Choosing a resin finish can enhance your surface's resilience, making it ideal for areas requiring prolonged protection and minimal maintenance.

Texture and Feel on Fabrics

Resin finish on fabrics creates a smooth, crisp texture that enhances wrinkle resistance and durability, offering a slightly stiff feel while maintaining fabric strength. Starch finish provides a more natural, light stiffness with a crisp touch, allowing fabric flexibility and breathability but with less long-term durability than resin. Both finishes improve fabric hand but resin imparts a glossier appearance and stronger tactile firmness compared to the softer, matte texture given by starch.

Impact on Appearance and Shine

Resin finishes provide a durable, high-gloss shine that enhances fabric color richness and creates a smooth, polished appearance. Starch finishes offer a crisp, matte look with moderate shine, giving fabrics a structured feel but less intensity in gloss. The choice between resin and starch finishes significantly impacts fabric texture and visual vibrancy, with resin delivering longer-lasting luster compared to the temporary brightness of starch.

Breathability and Comfort

Resin finish creates a durable, water-resistant layer on fabric, reducing its breathability and potentially causing discomfort during extended wear. Starch finish maintains fabric softness and allows better airflow, enhancing breathability and overall comfort. For garments prioritizing ventilation and ease, starch finish is preferable, while resin finish suits items needing stiffness and wrinkle resistance.

Care and Maintenance Requirements

Resin finish offers superior durability and water resistance, requiring minimal maintenance and simple cleaning with mild soap and water to maintain its smooth surface. Starch finish, while biologically derived and offering a natural matte look, demands more frequent reapplications and careful handling to avoid moisture damage and wear. Your choice between these finishes affects the time and effort spent on upkeep, with resin finishes being more cost-effective in the long term due to their low maintenance needs.

Environmental Impact and Sustainability

Resin finishes typically involve synthetic chemicals that can release volatile organic compounds (VOCs), contributing to environmental pollution and posing sustainability challenges. Starch finishes, derived from natural plant sources like corn or potatoes, are biodegradable and offer a more eco-friendly alternative with lower carbon footprints. Choosing a starch finish supports sustainable practices by reducing chemical waste and promoting renewable resources for Your textile or paper products.

Cost Analysis: Resin vs Starch Finishes

Resin finishes generally have a higher upfront cost compared to starch finishes due to the complexity of the chemical formulation and processing involved. Starch finishes tend to be more budget-friendly, making them an attractive option for projects with strict cost constraints while providing adequate surface protection and texture. Your choice should consider the durability and long-term maintenance expenses, where resin finishes might offer better cost-efficiency over time despite the initial investment.

Best Use Cases for Resin and Starch Finishes

Resin finishes are best suited for applications requiring durable, water-resistant, and long-lasting coatings, such as in outdoor furniture, automotive parts, and industrial surfaces. Starch finishes excel in textiles and paper products where biodegradability, ease of repair, and temporary stiffness are desired, like in garment finishing and wallpaper applications. Choosing between resin and starch finishes depends on the need for durability versus environmental friendliness and renewability.

Resin finish vs Starch finish Infographic

libmatt.com

libmatt.com