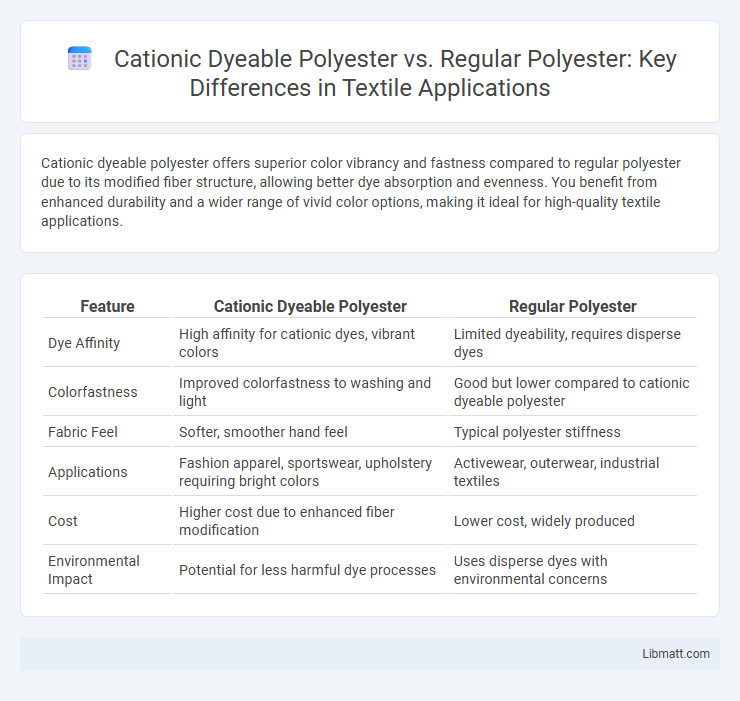

Cationic dyeable polyester offers superior color vibrancy and fastness compared to regular polyester due to its modified fiber structure, allowing better dye absorption and evenness. You benefit from enhanced durability and a wider range of vivid color options, making it ideal for high-quality textile applications.

Table of Comparison

| Feature | Cationic Dyeable Polyester | Regular Polyester |

|---|---|---|

| Dye Affinity | High affinity for cationic dyes, vibrant colors | Limited dyeability, requires disperse dyes |

| Colorfastness | Improved colorfastness to washing and light | Good but lower compared to cationic dyeable polyester |

| Fabric Feel | Softer, smoother hand feel | Typical polyester stiffness |

| Applications | Fashion apparel, sportswear, upholstery requiring bright colors | Activewear, outerwear, industrial textiles |

| Cost | Higher cost due to enhanced fiber modification | Lower cost, widely produced |

| Environmental Impact | Potential for less harmful dye processes | Uses disperse dyes with environmental concerns |

Understanding Polyester: An Overview

Cationic dyeable polyester is engineered at the molecular level to attract and bind cationic (basic) dyes, enabling vibrant colors that regular polyester, which primarily accepts disperse dyes, cannot achieve easily. This modification enhances the dye affinity and colorfastness, making cationic dyeable polyester ideal for fashion and home textiles demanding bright, long-lasting hues. Understanding these differences can help you select the right polyester type based on your fabric dyeing needs and desired color performance.

What is Cationic Dyeable Polyester?

Cationic dyeable polyester is a type of polyester fiber engineered to easily absorb cationic (positively charged) dyes, resulting in vibrant, long-lasting colors. Unlike regular polyester, which requires disperse dyes and high temperature for color fixation, cationic dyeable polyester offers enhanced dyeability, improved color fastness, and energy-efficient dyeing processes. Your choice of cationic dyeable polyester ensures brighter fabric hues with greater environmental sustainability compared to conventional polyester.

Regular Polyester: Properties and Uses

Regular polyester is a durable synthetic fiber known for its high strength, wrinkle resistance, and moisture-wicking properties, making it ideal for a wide range of applications such as apparel, home furnishings, and industrial textiles. It offers excellent chemical resistance and dimensional stability, but its hydrophobic nature limits dye absorption, resulting in colorfastness challenges with conventional dyes. Your choice of regular polyester suits environments requiring robust performance and easy maintenance, though color vibrancy may be enhanced by using specialized dyeing methods like disperse dyes.

Key Differences in Dyeability

Cationic dyeable polyester contains chemical modifications that allow it to bond with cationic (basic) dyes, enabling vibrant colors and enhanced dye uptake compared to regular polyester. Regular polyester primarily accepts disperse dyes, which require high temperatures and pressure for proper coloration, resulting in less vivid and less uniform dyeing. The unique dyeability of cationic polyester improves colorfastness, reduces environmental impact during dyeing, and broadens its applications in fashion and home textiles.

Color Fastness Comparison

Cationic dyeable polyester exhibits superior color fastness compared to regular polyester due to its enhanced affinity for water-soluble cationic dyes, resulting in deeper, more vibrant colors that resist fading from washing and exposure to light. Regular polyester relies primarily on disperse dyes, which tend to have lower wash and light fastness, leading to quicker color degradation over time. The molecular structure of cationic dyeable polyester allows better dye penetration and fixation, improving overall durability and longevity of the dyed fabric.

Processing Techniques for Both Polymers

Cationic dyeable polyester requires specialized processing techniques such as modified melt spinning and the incorporation of cationic sites during polymerization to enhance dye affinity, unlike regular polyester which follows standard melt spinning methods. Cationic dyeable polyester also benefits from lower temperature dyeing processes, reducing energy consumption and improving color uniformity compared to high-temperature dyeing required for regular polyester. Both polymers undergo similar downstream processes like weaving and finishing, but the dyeing stage for cationic dyeable polyester is optimized for environmentally friendly and efficient coloration.

Cost Implications: Cationic vs Regular Polyester

Cationic dyeable polyester typically incurs higher production costs than regular polyester due to specialized polymer modification and dyeing processes, impacting your overall budget for textile manufacturing. While regular polyester offers cost-efficiency in large-scale production, cationic dyeable polyester provides advantages in vibrant color yield and reduced water usage during dyeing, which may offset initial expenses over time. Evaluating your project priorities between upfront material costs and long-term environmental benefits can guide the most cost-effective choice.

Environmental Impact and Sustainability

Cationic dyeable polyester reduces environmental impact through lower water and energy consumption in the dyeing process compared to regular polyester, which requires high temperatures and extensive chemical use. The enhanced dye affinity of cationic dyeable polyester leads to less dye and fewer effluents, contributing to improved sustainability. This innovation supports circular economy goals by enabling easier recycling and reduced chemical pollution in textile manufacturing.

Applications in Textile Industry

Cationic dyeable polyester is extensively used in high-performance activewear, uniforms, and fashion textiles where vibrant, long-lasting colors are essential, enhancing fabric appeal and durability. Unlike regular polyester, which primarily relies on disperse dyes and yields less vivid hues, cationic dyeable polyester allows direct application of cationic dyes, enabling brighter, more saturated colors with improved colorfastness. This enhanced coloration capability drives demand for cationic dyeable polyester in sectors requiring durable, color-intensive textile solutions such as sportswear, home furnishings, and industrial uniforms.

Choosing the Right Polyester for Your Needs

Cationic dyeable polyester offers superior color vibrancy and faster dyeing processes compared to regular polyester, making it ideal for applications requiring rich, lasting colors. Your choice should consider whether enhanced dyeability and colorfastness are priorities, as cationic dyeable polyester provides better affinity for acid and disperse dyes. Regular polyester remains a cost-effective option for durable, versatile fabrics where intense coloration is less critical.

Cationic dyeable polyester vs Regular polyester Infographic

libmatt.com

libmatt.com