Cationic softeners contain positively charged ions that effectively bind to negatively charged fabric fibers, providing superior softness and static reduction in Your laundry. Nonionic softeners lack a charge, making them less effective on synthetic fabrics but ideal for delicate materials and providing gentle conditioning without buildup.

Table of Comparison

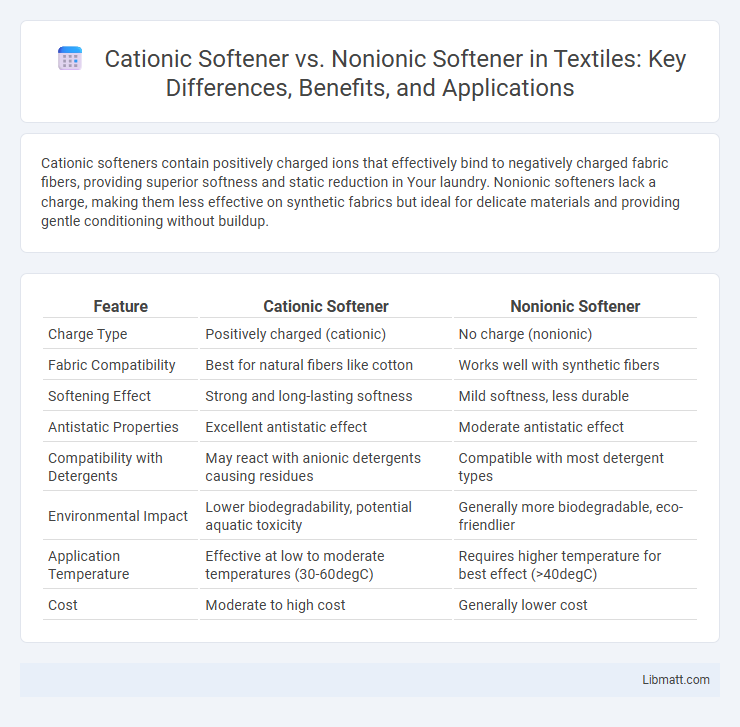

| Feature | Cationic Softener | Nonionic Softener |

|---|---|---|

| Charge Type | Positively charged (cationic) | No charge (nonionic) |

| Fabric Compatibility | Best for natural fibers like cotton | Works well with synthetic fibers |

| Softening Effect | Strong and long-lasting softness | Mild softness, less durable |

| Antistatic Properties | Excellent antistatic effect | Moderate antistatic effect |

| Compatibility with Detergents | May react with anionic detergents causing residues | Compatible with most detergent types |

| Environmental Impact | Lower biodegradability, potential aquatic toxicity | Generally more biodegradable, eco-friendlier |

| Application Temperature | Effective at low to moderate temperatures (30-60degC) | Requires higher temperature for best effect (>40degC) |

| Cost | Moderate to high cost | Generally lower cost |

Introduction to Textile Softeners

Cationic softeners contain positively charged surfactants that bind effectively to negatively charged fabric fibers, providing enhanced softness, static reduction, and improved dye retention in textiles. Nonionic softeners, lacking a charge, offer excellent compatibility with various fabric types and detergents, resulting in gentle softening without affecting fabric color or absorbency. Both types play crucial roles in textile finishing, influencing hand feel, durability, and overall fabric performance.

What is a Cationic Softener?

A cationic softener is a type of fabric softener composed of positively charged surfactants that neutralize static electricity and reduce fabric stiffness. It effectively interacts with negatively charged fibers, such as cotton, to enhance softness and improve fabric feel after washing. You can identify cationic softeners by their superior antistatic and conditioning properties compared to nonionic softeners.

What is a Nonionic Softener?

A nonionic softener is a type of fabric softener that does not carry any electrical charge, making it compatible with a wide range of laundry detergents and water conditions. These softeners work by depositing lubricating molecules on fabric fibers, enhancing softness without the risk of interacting negatively with anionic detergents. Nonionic softeners are particularly effective in hard water environments due to their stability and resistance to forming insoluble salts.

Chemical Structure Differences

Cationic softeners contain positively charged quaternary ammonium groups that enable strong attraction to negatively charged fabric fibers, providing enhanced softness and static control. Nonionic softeners lack charged groups and consist mainly of ethoxylated fatty alcohols, which offer milder softening effects and improved compatibility with various detergents. The distinct chemical structures influence their adsorption mechanisms, fabric affinity, and overall softening performance in textile applications.

Application Methods in Textile Processing

Cationic softeners are primarily applied through padding and exhaustion methods, enhancing fabric softness and antistatic properties by bonding with negatively charged fibers such as cotton and wool. Nonionic softeners are typically used in the padding process or as a finishing bath, offering excellent compatibility with various fiber types due to their neutrality, improving fabric handfeel without affecting dye uptake. Both softeners can be incorporated during the final rinse or finishing stage, with cationic types favoring natural fibers and nonionic types suited for synthetic blends.

Effects on Fabric Properties

Cationic softeners impart excellent antistatic properties and enhance fabric softness by forming a durable lubricating layer on fibers, improving wrinkle recovery and reducing friction between yarns. Nonionic softeners primarily increase fabric smoothness and sheen without significantly altering the fabric's electrostatic behavior, making them ideal for delicate materials where softness without residue is desired. The choice between cationic and nonionic softeners depends on desired fabric characteristics such as durability, softness, and antistatic performance.

Compatibility with Other Finishing Agents

Cationic softeners exhibit excellent compatibility with anionic finishing agents due to their positive charge, which allows them to bond effectively with negatively charged fibers, enhancing fabric softness and durability. Nonionic softeners offer broader compatibility across a wide range of finishing agents, including anionic, cationic, and nonionic types, making them versatile for use in complex finishing formulations. Your choice between cationic and nonionic softeners should factor in the specific finishing agents in your formulation to ensure optimal fabric performance and stability.

Environmental Impact and Safety

Cationic softeners, derived from quaternary ammonium compounds, often pose higher environmental risks due to their slow biodegradability and potential aquatic toxicity. Nonionic softeners, typically made from ethoxylated alcohols, offer better biodegradability and lower ecotoxicity, contributing to safer aquatic environments. Safety profiles favor nonionic softeners as they cause less skin irritation and have reduced bioaccumulation tendencies compared to cationic softeners.

Cost-Effectiveness Analysis

Cationic softeners generally offer greater cost-effectiveness due to their strong affinity for fabric fibers, requiring lower application rates to achieve desired softness and antistatic properties. Nonionic softeners, while milder and more compatible with various formulations, often demand higher concentrations, increasing overall usage and expense. Your choice should balance initial material costs with performance efficiency to optimize budget and fabric care outcomes.

Choosing the Right Softener for Your Needs

Cationic softeners are ideal for fabric softening due to their positive charge, which binds effectively to negatively charged fibers, enhancing softness and reducing static cling. Nonionic softeners offer versatile applications beyond textiles, excelling in emulsification and compatibility with various detergent formulations without causing residue or interaction issues. Selecting the right softener depends on fabric type, application method, and desired performance, with cationic softeners favored for laundry softness and nonionic softeners preferred for broader industrial and cleaning uses.

Cationic softener vs Nonionic softener Infographic

libmatt.com

libmatt.com