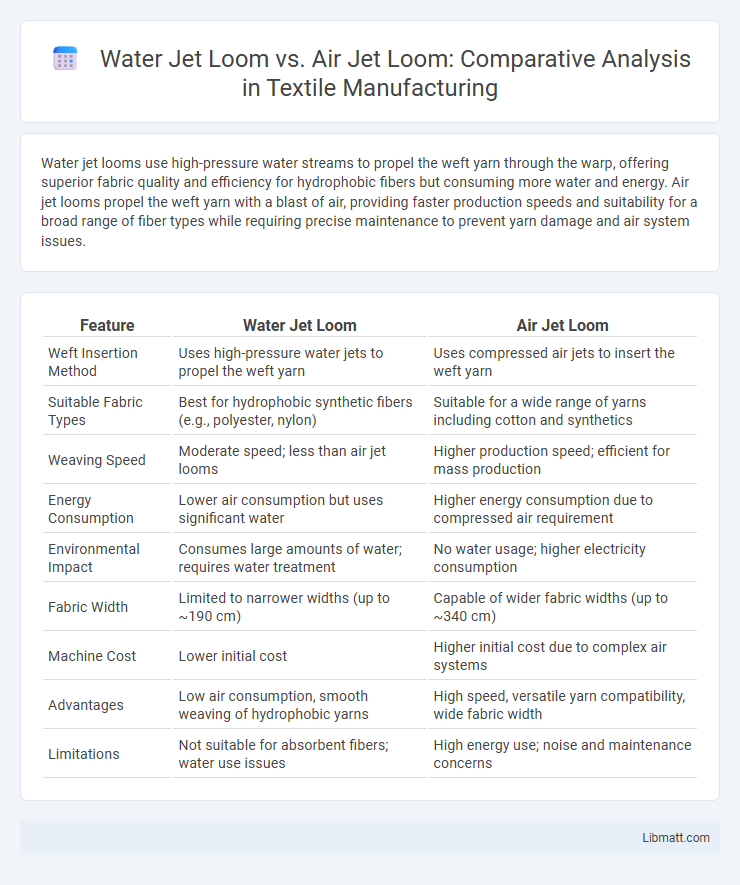

Water jet looms use high-pressure water streams to propel the weft yarn through the warp, offering superior fabric quality and efficiency for hydrophobic fibers but consuming more water and energy. Air jet looms propel the weft yarn with a blast of air, providing faster production speeds and suitability for a broad range of fiber types while requiring precise maintenance to prevent yarn damage and air system issues.

Table of Comparison

| Feature | Water Jet Loom | Air Jet Loom |

|---|---|---|

| Weft Insertion Method | Uses high-pressure water jets to propel the weft yarn | Uses compressed air jets to insert the weft yarn |

| Suitable Fabric Types | Best for hydrophobic synthetic fibers (e.g., polyester, nylon) | Suitable for a wide range of yarns including cotton and synthetics |

| Weaving Speed | Moderate speed; less than air jet looms | Higher production speed; efficient for mass production |

| Energy Consumption | Lower air consumption but uses significant water | Higher energy consumption due to compressed air requirement |

| Environmental Impact | Consumes large amounts of water; requires water treatment | No water usage; higher electricity consumption |

| Fabric Width | Limited to narrower widths (up to ~190 cm) | Capable of wider fabric widths (up to ~340 cm) |

| Machine Cost | Lower initial cost | Higher initial cost due to complex air systems |

| Advantages | Low air consumption, smooth weaving of hydrophobic yarns | High speed, versatile yarn compatibility, wide fabric width |

| Limitations | Not suitable for absorbent fibers; water use issues | High energy use; noise and maintenance concerns |

Introduction to Water Jet Looms and Air Jet Looms

Water jet looms utilize high-pressure water streams to propel the weft yarn through the shed, offering superior weaving speed and suitability for hydrophobic fibers like polyester. Air jet looms employ compressed air jets to insert the weft yarn, providing high efficiency and adaptability for synthetic and fine yarns with reduced yarn breakage. Both loom types are integral in modern textile manufacturing, enhancing fabric production quality and operational economy by leveraging fluid dynamics for weft insertion.

Basic Working Principles

Water jet looms use a high-pressure stream of water to propel the weft yarn through the warp shed, making them ideal for weaving hydrophobic fibers. Air jet looms, on the other hand, utilize compressed air blasts to insert the weft yarn, offering higher speeds and versatility across various fiber types. Your choice between these two depends on fabric requirements, yarn characteristics, and energy efficiency considerations.

Key Technological Differences

Water jet looms use high-pressure water streams to propel the weft yarn through the warp shed, enabling efficient weaving of hydrophobic fibers like polyester. Air jet looms rely on compressed air to carry the yarn, offering faster insertion rates and better versatility with lightweight yarns but consuming more energy. The key technological difference lies in the propulsion mechanism--water jet looms use fluid dynamics with water as the medium, while air jet looms utilize pneumatic forces for yarn insertion.

Efficiency and Production Speed Comparison

Water jet looms offer high efficiency in weaving fine to medium fabrics due to precise water-driven weft insertion, achieving speeds up to 1000 picks per minute. Air jet looms surpass water jet looms in production speed for heavier and coarser fabrics, often reaching speeds exceeding 1200 picks per minute by propelling the weft yarn with compressed air. Efficiency comparisons indicate water jet looms consume less energy and produce minimal noise, while air jet looms provide greater versatility in yarn types and higher productivity for industrial-scale textile manufacturing.

Fabric Quality and Versatility

Water jet looms produce finer, smoother fabrics with minimal yarn stress, ideal for delicate materials like synthetics, while air jet looms offer superior versatility by efficiently handling a wider variety of yarn types and fabric weights. Fabric quality in water jet looms is enhanced by precise water flow control, resulting in consistent texture and reduced defects. Air jet looms excel in versatility due to faster production speeds and adaptability to different weaving patterns, making them suitable for both lightweight and medium-weight fabrics.

Energy Consumption and Operational Costs

Water jet looms typically consume less energy compared to air jet looms due to the lower power requirements of water propulsion versus compressed air systems. Operational costs for water jet looms are often lower because they use water as the weft insertion medium, reducing the expenses related to maintaining high-pressure air compressors. However, air jet looms may incur higher energy consumption and operational costs due to the continuous need for compressed air generation and maintenance.

Maintenance and Durability

Water jet looms require less frequent maintenance due to their stable water propulsion system, which reduces mechanical wear compared to air jet looms. Air jet looms, relying on high-pressure air, demand regular cleaning and servicing of air compressors and nozzles to maintain performance and durability. You can expect longer lifespan and lower upkeep costs with water jet looms, especially in environments with easy access to clean water.

Applications in the Textile Industry

Water jet looms excel in weaving hydrophobic synthetic fibers such as polyester and nylon due to their use of high-pressure water streams, making them ideal for producing lightweight and breathable fabrics. Air jet looms are better suited for weaving cotton, wool, and blended yarns because of their air-based weft insertion, delivering higher speeds and versatility in fabric types. Your choice between these technologies depends on the specific textile application, fabric requirements, and production efficiency needed in your manufacturing process.

Environmental Impact and Sustainability

Water jet looms consume significant amounts of water, making them less sustainable in regions facing water scarcity despite their energy efficiency compared to air jet looms. Air jet looms use compressed air, which requires substantial electrical energy, contributing to higher carbon emissions, but they avoid water usage altogether. Your choice between these looms impacts environmental sustainability based on local resource availability and energy sourcing.

Choosing the Right Loom for Your Needs

Water jet looms use pressurized water to propel weft yarn, offering high-speed weaving ideal for hydrophobic fibers like polyester and nylon. Air jet looms utilize air pulses to insert the weft, providing versatility for a wide range of yarn types, including delicate and natural fibers like cotton and wool. Your choice between these looms should consider fabric type, production speed, energy consumption, and maintenance requirements to optimize efficiency and fabric quality.

Water jet loom vs Air jet loom Infographic

libmatt.com

libmatt.com