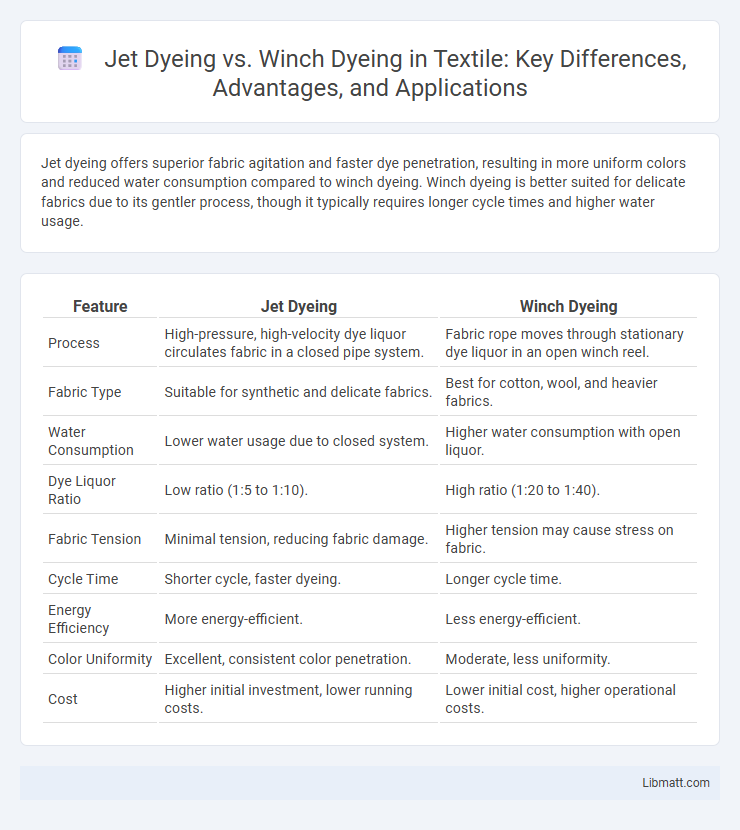

Jet dyeing offers superior fabric agitation and faster dye penetration, resulting in more uniform colors and reduced water consumption compared to winch dyeing. Winch dyeing is better suited for delicate fabrics due to its gentler process, though it typically requires longer cycle times and higher water usage.

Table of Comparison

| Feature | Jet Dyeing | Winch Dyeing |

|---|---|---|

| Process | High-pressure, high-velocity dye liquor circulates fabric in a closed pipe system. | Fabric rope moves through stationary dye liquor in an open winch reel. |

| Fabric Type | Suitable for synthetic and delicate fabrics. | Best for cotton, wool, and heavier fabrics. |

| Water Consumption | Lower water usage due to closed system. | Higher water consumption with open liquor. |

| Dye Liquor Ratio | Low ratio (1:5 to 1:10). | High ratio (1:20 to 1:40). |

| Fabric Tension | Minimal tension, reducing fabric damage. | Higher tension may cause stress on fabric. |

| Cycle Time | Shorter cycle, faster dyeing. | Longer cycle time. |

| Energy Efficiency | More energy-efficient. | Less energy-efficient. |

| Color Uniformity | Excellent, consistent color penetration. | Moderate, less uniformity. |

| Cost | Higher initial investment, lower running costs. | Lower initial cost, higher operational costs. |

Introduction to Jet Dyeing and Winch Dyeing

Jet dyeing utilizes high-pressure jets to circulate fabric through a dye bath, offering efficient color penetration and uniformity for knitwear and woven textiles. Winch dyeing employs a winch reel to continuously move fabric through dye liquor in a gentle, low-tension process ideal for delicate or open-mesh fabrics. Understanding these methods helps you select the best technique for fabric type, dye absorption, and production scale.

Historical Overview of Dyeing Techniques

Jet dyeing originated in the early 20th century as an innovative technique to improve fabric dyeing efficiency using high-velocity water jets, while winch dyeing dates back to the 19th century, relying on a paddle-like winch to circulate fabric through dye liquor. The historical evolution of jet dyeing reflects advancements in textile machinery aimed at reducing water and energy consumption compared to the more traditional winch dyeing process. Understanding these methods highlights how your choice of dyeing technique can impact color uniformity and environmental sustainability.

Fundamental Principles of Jet Dyeing

Jet dyeing operates on the principle of circulating fabric through a closed-loop system using a high-velocity jet of dye liquor, which ensures rapid and uniform penetration of color. The fabric, typically in rope form, is transported continuously under controlled tension, enhancing dye uptake and minimizing mechanical stress. This method optimizes dye liquor utilization and temperature control, resulting in consistent fabric quality and reduced processing time compared to traditional winch dyeing.

Core Concepts of Winch Dyeing

Winch dyeing involves fabric being continuously looped through a dye bath, immersing and circulating the material to ensure even color absorption, which suits lightweight and delicate fabrics. This process uses a winch reel to guide the fabric gently, minimizing tension and damage while providing uniform dye penetration. Your choice of winch dyeing is ideal when handling fine fabrics requiring controlled, low-tension dyeing for consistent, high-quality coloration.

Equipment and Machinery Differences

Jet dyeing machines use high-pressure jets to propel fabric through the dye liquor, enabling faster processing and better fabric penetration, while winch dyeing relies on a reel and roller system where fabric is continuously cycled through the dye bath. Jet dyeing equipment features closed-loop systems with advanced control panels for pressure and temperature regulation, promoting energy efficiency and uniform dyeing. In contrast, winch dyeing machines are typically larger, open machines requiring more water and energy, suitable for delicate fabrics but less efficient in terms of process control and environmental impact.

Process Workflow: Jet vs Winch Dyeing

Jet dyeing uses a high-velocity jet of dye liquor to circulate fabric in a closed loop, ensuring even color penetration and faster processing times compared to Winch dyeing. Winch dyeing involves fabric being sewn into a loose rope and continuously circulated through a dye bath over a winch reel, causing greater mechanical stress and longer dyeing cycles. Jet dyeing is more efficient for delicate fabrics due to reduced tension and improved liquor utilization, whereas Winch dyeing suits heavy and coarse fabrics with less stringent dye uniformity requirements.

Fabric Compatibility and Applications

Jet dyeing is ideal for lightweight and knit fabrics such as polyester, nylon, and blends, offering excellent color uniformity and suitability for delicate materials. Winch dyeing excels with woven fabrics like cotton, wool, and linen, delivering soft hand feel and is commonly used for denim, shirting, and upholstery textiles. Your choice depends on the fabric type and desired end-use, with jet dyeing favored for synthetic fibers and winch dyeing preferred for natural fibers and heavier textiles.

Efficiency and Production Speeds

Jet dyeing offers higher efficiency and faster production speeds compared to winch dyeing due to its continuous fabric circulation and controlled dye liquor flow, which ensures uniform dyeing with reduced processing time. Winch dyeing, while effective for delicate fabrics, operates at slower speeds because it relies on a gentle winching motion that limits production capacity. Choosing jet dyeing can significantly boost your output and reduce energy consumption in high-volume textile manufacturing.

Environmental Impact and Sustainability

Jet dyeing uses less water and energy compared to Winch dyeing, significantly reducing environmental impact. Winch dyeing consumes more water and chemicals, increasing the potential for pollution and waste. Your choice of dyeing method can influence the sustainability of textile production by minimizing resource use and lowering harmful effluents.

Choosing the Right Dyeing Method

Choosing the right dyeing method depends on fabric type, production volume, and desired color uniformity, with jet dyeing offering high-speed, uniform dyeing ideal for lightweight and delicate textiles, while winch dyeing suits heavier and more textured fabrics due to its gentle treatment. Jet dyeing uses high-pressure jets to circulate fabric efficiently, reducing water and energy consumption, whereas winch dyeing operates at lower temperatures with slower fabric movement, which can be beneficial for certain fiber types sensitive to mechanical stress. Your selection should align with the fabric characteristics and sustainability goals to optimize quality and operational costs effectively.

Jet dyeing vs Winch dyeing Infographic

libmatt.com

libmatt.com