Slasher sizing involves applying sizing agents to fabric before weaving, enhancing the yarn's strength and water resistance during the weaving process, while sheet sizing applies sizing to completed fabric sheets, improving surface smoothness and printability. Your choice between these methods depends on whether you prioritize yarn protection during weaving or fabric finish quality post-weaving.

Table of Comparison

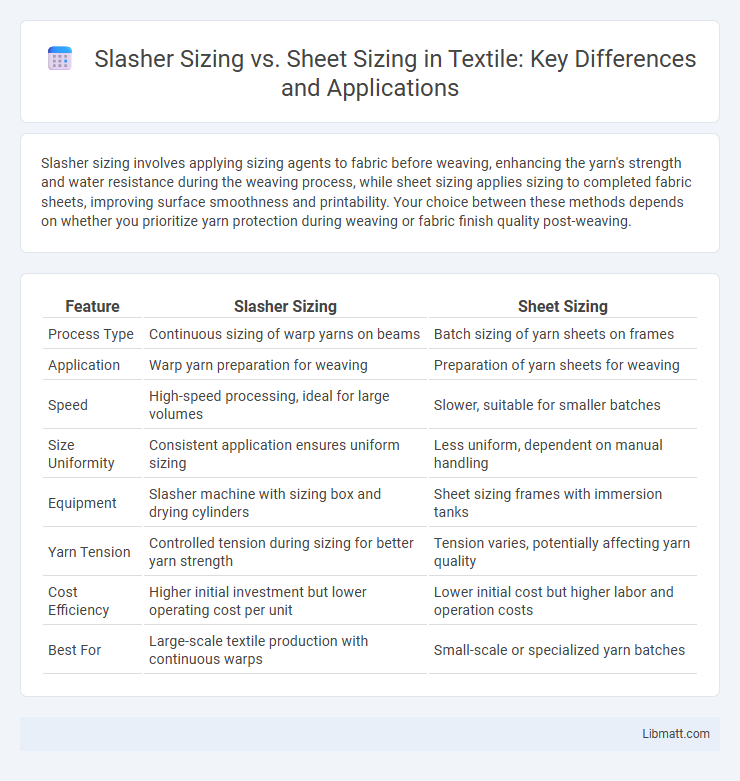

| Feature | Slasher Sizing | Sheet Sizing |

|---|---|---|

| Process Type | Continuous sizing of warp yarns on beams | Batch sizing of yarn sheets on frames |

| Application | Warp yarn preparation for weaving | Preparation of yarn sheets for weaving |

| Speed | High-speed processing, ideal for large volumes | Slower, suitable for smaller batches |

| Size Uniformity | Consistent application ensures uniform sizing | Less uniform, dependent on manual handling |

| Equipment | Slasher machine with sizing box and drying cylinders | Sheet sizing frames with immersion tanks |

| Yarn Tension | Controlled tension during sizing for better yarn strength | Tension varies, potentially affecting yarn quality |

| Cost Efficiency | Higher initial investment but lower operating cost per unit | Lower initial cost but higher labor and operation costs |

| Best For | Large-scale textile production with continuous warps | Small-scale or specialized yarn batches |

Introduction to Sizing in Textile Manufacturing

Sizing in textile manufacturing involves applying a protective adhesive coating on yarns to reduce breakage during weaving. Slasher sizing treats multiple warp yarns simultaneously by passing them through a sizing solution, offering high efficiency for large-scale production. In contrast, sheet sizing applies the solution in a thin, uniform layer onto individual yarn sheets, providing precise control for specialized fabrics.

Understanding Slasher Sizing: Definition & Process

Slasher sizing is a textile finishing process where a liquid sizing agent is applied to fabric, enhancing yarn strength and fabric smoothness before weaving. Unlike sheet sizing, which involves immersing entire fabric sheets in the sizing solution, slasher sizing targets the warp yarns directly through a controlled application, offering precise control over the amount of size applied. Your choice between slasher sizing and sheet sizing impacts fabric durability and weaving efficiency based on the specific production requirements.

Understanding Sheet Sizing: Definition & Process

Sheet sizing involves applying a thin layer of adhesive or starch to paper or cardboard sheets to enhance their surface strength, printability, and resistance to moisture. Unlike slasher sizing, which is applied during the pulp stage or in the wet formation of paper, sheet sizing occurs after the sheet is formed, typically via surface coating or size press application. Understanding this process helps you improve the quality and durability of your paper products by controlling factors such as absorbency and surface smoothness.

Key Differences Between Slasher Sizing and Sheet Sizing

Slasher sizing applies sizing chemicals to yarns on a warp beam before weaving, enhancing fabric strength and smoothness by improving yarn cohesion. Sheet sizing, on the other hand, involves coating the entire woven fabric with sizing agents to improve surface properties such as stiffness and abrasion resistance. Key differences include the stage of application--slasher sizing occurs pre-weaving on yarns, while sheet sizing takes place post-weaving on fabric--and the specific performance enhancements targeted by each method.

Advantages of Slasher Sizing

Slasher sizing offers precise control over the amount of sizing applied to yarn, resulting in improved fabric strength and reduced warp breakage during weaving. This technique enhances sizing uniformity and ensures better penetration of sizing agents, leading to increased efficiency in the textile production process. Compared to sheet sizing, slasher sizing minimizes waste and reduces water and energy consumption, contributing to cost savings and environmental sustainability.

Advantages of Sheet Sizing

Sheet sizing offers enhanced surface uniformity and improved adhesion properties, making it ideal for high-quality printing and coating applications. Its ability to provide consistent coverage reduces material waste and increases production efficiency. Compared to slasher sizing, sheet sizing ensures better control over moisture content, resulting in stronger, more durable paper products.

Limitations of Slasher Sizing

Slasher sizing often faces limitations in achieving uniform application of sizing chemicals on yarns, leading to inconsistent fabric quality especially in high-speed weaving operations. This method restricts the ability to adjust sizing formulation dynamically, reducing efficiency for diverse textile materials and complex fabric constructions. Compared to sheet sizing, slasher sizing provides less control over penetration and drying, which can negatively impact fabric strength and machinability.

Limitations of Sheet Sizing

Sheet sizing faces limitations such as uneven coating distribution and reduced efficiency when applied to thicker or larger sheets. It often results in higher waste due to edge losses and difficulty achieving uniform adhesion on varied sheet textures. These constraints limit its effectiveness compared to slasher sizing, which offers more precise control and better performance for continuous web processes.

Slasher Sizing vs Sheet Sizing: Application Suitability

Slasher sizing enhances fabric strength and printability for woven and knit textiles, making it ideal for large-scale production requiring uniform coating. Sheet sizing, applied to flat fabric panels or sheets, suits specialty textiles and smaller runs where precise control over application is crucial. Both methods optimize adhesion and durability but differ in scalability and fabric handling capabilities.

Future Trends in Textile Sizing Technologies

Slasher sizing, relying on traditional wet-sizing techniques, faces challenges in efficiency and sustainability compared to innovative sheet sizing technologies that utilize pre-sized sheets for enhanced precision and reduced water consumption. Future trends highlight the integration of bio-based and enzymatic sizing agents in sheet sizing to improve fabric strength while minimizing environmental impact. You can expect advances in digital control systems and real-time monitoring to optimize sizing processes, increasing productivity and fabric quality in textile manufacturing.

Slasher sizing vs Sheet sizing Infographic

libmatt.com

libmatt.com