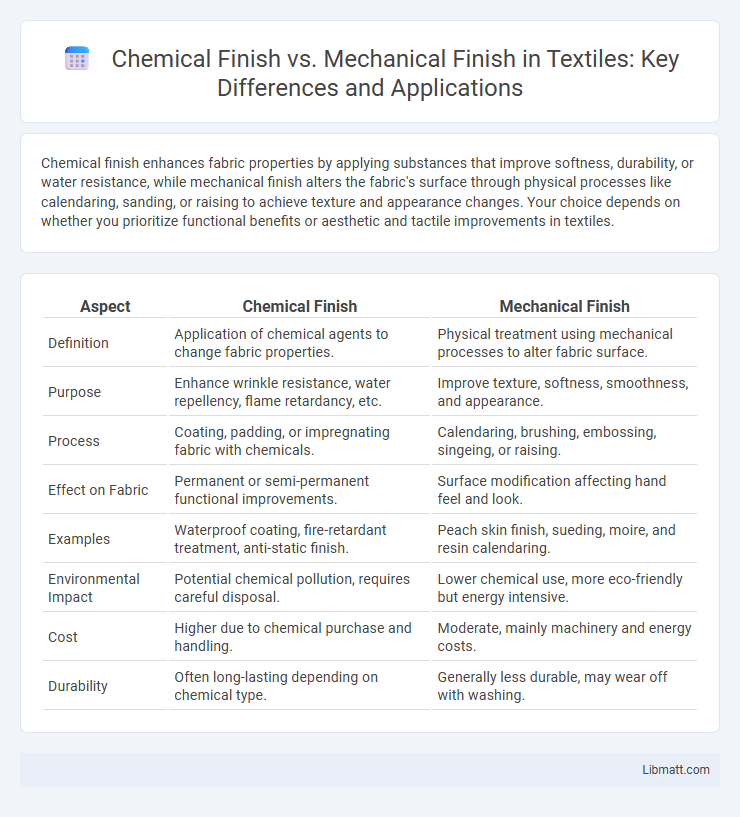

Chemical finish enhances fabric properties by applying substances that improve softness, durability, or water resistance, while mechanical finish alters the fabric's surface through physical processes like calendaring, sanding, or raising to achieve texture and appearance changes. Your choice depends on whether you prioritize functional benefits or aesthetic and tactile improvements in textiles.

Table of Comparison

| Aspect | Chemical Finish | Mechanical Finish |

|---|---|---|

| Definition | Application of chemical agents to change fabric properties. | Physical treatment using mechanical processes to alter fabric surface. |

| Purpose | Enhance wrinkle resistance, water repellency, flame retardancy, etc. | Improve texture, softness, smoothness, and appearance. |

| Process | Coating, padding, or impregnating fabric with chemicals. | Calendaring, brushing, embossing, singeing, or raising. |

| Effect on Fabric | Permanent or semi-permanent functional improvements. | Surface modification affecting hand feel and look. |

| Examples | Waterproof coating, fire-retardant treatment, anti-static finish. | Peach skin finish, sueding, moire, and resin calendaring. |

| Environmental Impact | Potential chemical pollution, requires careful disposal. | Lower chemical use, more eco-friendly but energy intensive. |

| Cost | Higher due to chemical purchase and handling. | Moderate, mainly machinery and energy costs. |

| Durability | Often long-lasting depending on chemical type. | Generally less durable, may wear off with washing. |

Introduction to Surface Finishes

Surface finishes enhance the appearance, durability, and functionality of materials through either chemical or mechanical methods. Chemical finishes use processes like etching, anodizing, or coating to alter the surface at a molecular level, improving corrosion resistance and wear properties. Mechanical finishes involve physical actions such as grinding, polishing, or blasting to create smooth, textured, or patterned surfaces, tailoring Your product's tactile feel and visual appeal.

Understanding Chemical Finishes

Chemical finishes involve applying substances like resins, waxes, or softeners to alter fabric properties, enhancing durability, water repellency, or wrinkle resistance. These finishes penetrate fibers at a molecular level to provide long-lasting effects compared to mechanical finishes, which physically alter fabric texture. Understanding chemical finishes helps you select textiles tailored for specific performance needs and care requirements.

Overview of Mechanical Finishes

Mechanical finishes involve physical processes such as sanding, grinding, or polishing to improve a material's surface texture and appearance. These finishes enhance durability, reduce surface roughness, and often increase resistance to wear without altering the material's chemical composition. Common mechanical finishes include buffing for shine, shot blasting for texture, and honing for smoothness, widely used in metalworking and manufacturing.

Key Processes in Chemical Finishing

Chemical finishing involves key processes such as dyeing, bleaching, softening, and water-repellent treatments, which alter the fabric's surface at a molecular level to enhance appearance, texture, and performance. These processes utilize chemical agents like mordants, surfactants, and fixatives to achieve desired properties such as color fastness, wrinkle resistance, and stain repellency. Unlike mechanical finishing, chemical finishing modifies the textile through reactions that improve durability and functionality without physical deformation.

Main Techniques in Mechanical Finishing

Mechanical finishing techniques primarily include grinding, polishing, and sandblasting, which physically alter the surface texture to improve smoothness and appearance. These methods enhance surface hardness, remove imperfections, and prepare materials for further processing or coating. Your choice of mechanical finishing will depend on the desired surface quality, material type, and application requirements.

Comparative Analysis: Chemical vs Mechanical Finish

Chemical finishes utilize reactive substances to alter the surface properties of materials, enhancing corrosion resistance and surface smoothness without affecting the underlying structure. Mechanical finishes rely on physical processes such as grinding, polishing, or sanding to improve surface texture and appearance, often resulting in dimensional changes or surface embossing. Comparing both, chemical finishes offer better precision in surface modification with minimal mechanical impact, whereas mechanical finishes provide tactile and aesthetic improvements but may induce surface stress or deformation.

Impact on Material Properties

Chemical finishes alter material properties by modifying surface chemistry, enhancing attributes like water repellency, stain resistance, or dye affinity without significant changes to mechanical strength. Mechanical finishes physically change the material's surface texture, affecting properties such as smoothness, gloss, or tensile strength due to processes like sanding, calendaring, or embossing. The choice between chemical and mechanical finishes directly influences durability, flexibility, and aesthetic qualities of textiles or metals.

Cost Efficiency and Economic Considerations

Chemical finishes generally offer lower upfront costs due to simpler application processes and reduced labor requirements, making them cost-efficient for large-scale production. Mechanical finishes often involve higher equipment investment and maintenance expenses but can deliver longer-lasting durability, which may reduce overall lifecycle costs. Economic considerations should weigh immediate cost savings of chemical finishes against potential long-term savings from the durability of mechanical finishes.

Environmental and Safety Aspects

Chemical finishes often involve hazardous substances that pose environmental risks such as water pollution and toxic waste generation, necessitating strict handling and disposal protocols to ensure worker safety. Mechanical finishes typically have a lower environmental impact since they rely on physical processes, reducing chemical use and associated pollutants, although they may consume significant energy and generate particulate emissions. Selecting finishes with sustainable materials and implementing safety measures minimizes ecological footprint and protects workers from chemical exposure and mechanical hazards.

Choosing the Right Finish for Your Application

Selecting the appropriate finish depends on the material properties and end-use requirements, where chemical finishes offer corrosion resistance and surface smoothness ideal for metals exposed to harsh environments. Mechanical finishes provide enhanced texture and durability, suitable for applications requiring increased wear resistance and aesthetic appeal. Evaluating factors such as environmental exposure, desired surface characteristics, and cost-efficiency ensures optimal performance and longevity for your specific application.

Chemical finish vs Mechanical finish Infographic

libmatt.com

libmatt.com