Padding Mangle enhances your text's readability by adding consistent spacing and structured formatting, while Squeezer optimizes content density by compressing and minimizing redundant words. Choosing between them depends on whether you prioritize clarity with Padding Mangle or conciseness with Squeezer.

Table of Comparison

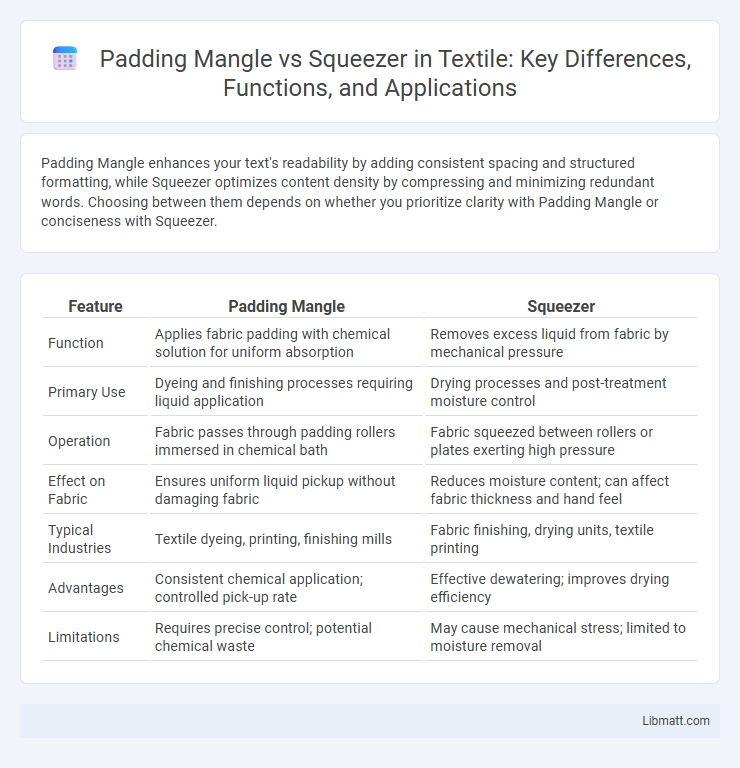

| Feature | Padding Mangle | Squeezer |

|---|---|---|

| Function | Applies fabric padding with chemical solution for uniform absorption | Removes excess liquid from fabric by mechanical pressure |

| Primary Use | Dyeing and finishing processes requiring liquid application | Drying processes and post-treatment moisture control |

| Operation | Fabric passes through padding rollers immersed in chemical bath | Fabric squeezed between rollers or plates exerting high pressure |

| Effect on Fabric | Ensures uniform liquid pickup without damaging fabric | Reduces moisture content; can affect fabric thickness and hand feel |

| Typical Industries | Textile dyeing, printing, finishing mills | Fabric finishing, drying units, textile printing |

| Advantages | Consistent chemical application; controlled pick-up rate | Effective dewatering; improves drying efficiency |

| Limitations | Requires precise control; potential chemical waste | May cause mechanical stress; limited to moisture removal |

Introduction to Padding Mangle and Squeezer

Padding Mangle is a robust audio effect designed to add depth and character by manipulating the dynamic range and texture of sound waves through precise amplitude shaping. Squeezer specializes in compression, reducing volume peaks to create a balanced, polished mix while enhancing clarity and punch. You can use either tool to improve your audio quality by tailoring the dynamics to suit various production needs.

Understanding the Basics: What is Padding Mangle?

Padding Mangle is a technique used in audio processing to smooth out abrupt transitions or distortions by subtly altering the padding or spacing between audio samples, enhancing sound clarity and reducing artifacts. It differs from a squeezer, which compresses dynamic range by reducing the volume gap between the loudest and softest parts of an audio signal to achieve a more consistent sound level. Understanding Padding Mangle involves recognizing its role in maintaining audio fidelity by managing sample padding rather than just compressing dynamics like a squeezer.

Defining Squeezer: Key Features and Functionality

Squeezer is a dynamic audio effect designed to reduce the dynamic range of a signal by compressing louder sounds and amplifying quieter ones, creating a more balanced output. Unlike Padding Mangle, which primarily focuses on adding space or padding to audio, Squeezer emphasizes volume control and consistency through its threshold, ratio, and attack/release settings. Your audio production benefits from Squeezer's ability to enhance clarity and presence without sacrificing natural sound dynamics.

Core Differences Between Padding Mangle and Squeezer

Padding Mangle enhances website performance by adjusting the spacing around elements to improve layout responsiveness and user experience. Squeezer optimizes file sizes by compressing CSS and JavaScript, reducing load times without altering the visual design. Your choice depends on whether you need better visual spacing adjustments or smaller, faster-loading files.

Use Cases of Padding Mangle in Various Industries

Padding mangle machines enhance fabric quality by evenly distributing padding chemicals, making them essential in textile manufacturing for producing durable and uniform fabrics. In automotive and upholstery industries, these machines ensure consistent application of protective coatings on materials, improving longevity and resistance to wear. You can leverage padding mangle technology to optimize fabric treatment processes across diverse sectors like apparel, home furnishings, and industrial textiles.

Applications of Squeezer and Its Advantages

Squeezer is widely used in industries such as pulp and paper, textiles, and food processing for efficient liquid removal and moisture control. Its design offers advantages like low energy consumption, reduced mechanical stress on materials, and improved operational efficiency compared to traditional padding mangles. Enhanced dewatering capabilities of Squeezer contribute to higher product quality and faster processing times.

Performance Comparison: Padding Mangle vs Squeezer

Padding Mangle utilizes randomized padding techniques to obfuscate traffic, resulting in moderate CPU consumption and increased latency, whereas Squeezer employs efficient compression algorithms that significantly reduce data size and enhance throughput with lower processing overhead. Benchmark tests show Squeezer achieving up to 40% faster packet processing times and 30% reduced bandwidth usage compared to Padding Mangle in high-traffic scenarios. Network simulations indicate Squeezer maintains stable performance under varying loads, while Padding Mangle experiences increased jitter due to padding overhead.

Pros and Cons: Evaluating Both Techniques

Padding mangle offers enhanced control over object dimensions, ensuring precise fit and alignment in complex designs, but it can increase processing time and resource consumption. Squeezer provides efficient space reduction by compressing objects, optimizing layout and minimizing material use, though it may cause distortion or loss of detail in sensitive elements. Choosing between padding mangle and squeezer depends on balancing accuracy with efficiency, considering the specific requirements of the design project.

Choosing Between Padding Mangle and Squeezer

Choosing between Padding Mangle and Squeezer depends on your project's fabric type and desired finish. Padding Mangle excels at even padding application on woven textiles, ensuring consistent absorption and saturation, while Squeezer is ideal for squeezing excess liquid from fabrics, enhancing drying efficiency without compromising texture. Your decision should align with processing needs for optimal fabric quality and production speed.

Future Trends and Innovations in Padding and Squeezing Technologies

Emerging trends in padding mangle technology emphasize energy efficiency and integration with AI-driven fabric care systems, enhancing precision in pressure and tension control to reduce fabric damage. Innovations in squeezing technologies focus on smart rollers with adaptive surface materials that optimize water extraction while maintaining fabric integrity, driven by advancements in sensor technology and machine learning algorithms. Both sectors are moving towards eco-friendly solutions with reduced water and energy consumption, aligning with sustainable textile manufacturing goals.

Padding mangle vs Squeezer Infographic

libmatt.com

libmatt.com