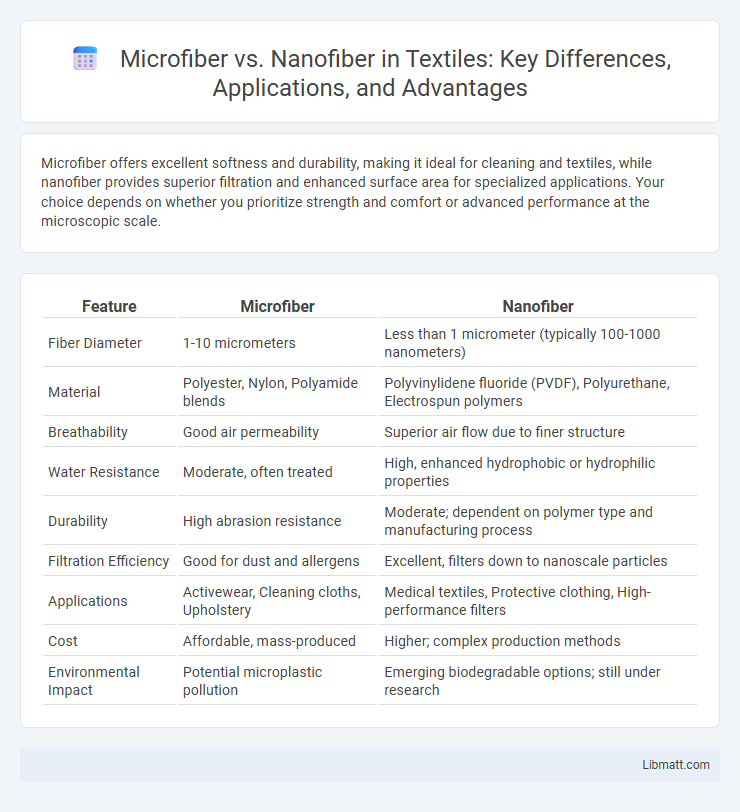

Microfiber offers excellent softness and durability, making it ideal for cleaning and textiles, while nanofiber provides superior filtration and enhanced surface area for specialized applications. Your choice depends on whether you prioritize strength and comfort or advanced performance at the microscopic scale.

Table of Comparison

| Feature | Microfiber | Nanofiber |

|---|---|---|

| Fiber Diameter | 1-10 micrometers | Less than 1 micrometer (typically 100-1000 nanometers) |

| Material | Polyester, Nylon, Polyamide blends | Polyvinylidene fluoride (PVDF), Polyurethane, Electrospun polymers |

| Breathability | Good air permeability | Superior air flow due to finer structure |

| Water Resistance | Moderate, often treated | High, enhanced hydrophobic or hydrophilic properties |

| Durability | High abrasion resistance | Moderate; dependent on polymer type and manufacturing process |

| Filtration Efficiency | Good for dust and allergens | Excellent, filters down to nanoscale particles |

| Applications | Activewear, Cleaning cloths, Upholstery | Medical textiles, Protective clothing, High-performance filters |

| Cost | Affordable, mass-produced | Higher; complex production methods |

| Environmental Impact | Potential microplastic pollution | Emerging biodegradable options; still under research |

Introduction to Microfiber and Nanofiber

Microfiber consists of synthetic fibers finer than one denier, typically made from polyester or nylon, renowned for their exceptional softness, durability, and moisture-wicking properties. Nanofibers feature even smaller diameters, often below 100 nanometers, produced using advanced electrospinning techniques that create ultra-fine fibers with high surface area-to-volume ratios. These nanoscale fibers enhance applications in filtration, medical textiles, and high-performance fabrics due to their improved strength, breathability, and contaminant capture efficiency.

Defining Microfiber: Composition and Properties

Microfiber consists of synthetic fibers finer than 10 microns, often made from polyester and nylon blends, offering exceptional softness, durability, and moisture-wicking properties. These ultra-fine fibers create a dense fabric structure that enhances breathability and resistance to wind and water, making microfiber suitable for athletic wear and cleaning products. The distinctive composition of microfiber allows it to trap dirt and liquids effectively, outperforming traditional fibers in both functionality and comfort.

Understanding Nanofiber: Structure and Characteristics

Nanofibers are ultra-fine fibers with diameters typically less than 100 nanometers, offering a significantly higher surface area to volume ratio compared to microfibers. Their unique structure enables exceptional properties such as enhanced filtration efficiency, superior mechanical strength, and increased porosity. These characteristics make nanofibers ideal for advanced applications in filtration, medical textiles, and high-performance composites.

Key Differences Between Microfiber and Nanofiber

Microfiber consists of synthetic fibers with diameters typically between 0.1 to 10 microns, while nanofiber features ultrafine fibers less than 100 nanometers in diameter, offering significantly higher surface area and filtration efficiency. Nanofiber materials provide superior strength, enhanced breathability, and finer filtration capabilities compared to microfiber, making them ideal for advanced applications in medical masks and air filters. Your choice between microfiber and nanofiber depends on the specific needs for durability, filtration precision, and moisture-wicking properties in textiles or filtration systems.

Manufacturing Processes: Microfiber vs Nanofiber

Microfiber production involves extrusion or spinning of polyester or nylon polymers into ultrafine fibers typically smaller than 10 microns, using methods like melt spinning or bicomponent spinning. Nanofiber manufacturing relies on advanced techniques such as electrospinning, which applies an electric field to draw charged polymer jets into fibers with diameters ranging from 1 to 100 nanometers, enabling precise control over fiber morphology. These distinct processes result in microfiber materials with robust mechanical properties, while nanofibers offer higher surface area-to-volume ratios and enhanced functional performance in filtration, medical, and textile applications.

Performance and Durability Comparison

Microfiber offers high absorbency and strength, making it effective for general cleaning and frequent use, while nanofiber excels in filtration and capturing smaller particles due to its finer fiber diameter. Nanofibers tend to have superior durability in high-precision applications but may degrade faster under abrasive conditions compared to the more robust microfiber. Performance efficiency varies by use case, with microfiber favored for bulk cleaning tasks and nanofiber preferred for advanced filtration and precision maintenance.

Applications in Industry: Microfiber vs Nanofiber

Microfiber, with fiber diameters typically between 0.1 and 10 microns, is widely used in industries such as automotive cleaning, textiles, and filtration due to its durability and excellent moisture absorption. Nanofiber, featuring fiber diameters less than 100 nanometers, finds critical applications in high-performance filtration, biomedical devices, and advanced sensors thanks to its superior surface area and nanoscale porosity. The choice between microfiber and nanofiber depends on specific industry requirements for filtration efficiency, mechanical strength, and functionalization capabilities.

Environmental Impact and Sustainability

Microfiber production consumes less energy compared to conventional fibers but often sheds microplastics during washing, contributing to ocean pollution. Nanofiber technology offers enhanced biodegradability and potential for recyclable materials, reducing long-term environmental harm. Your choice between microfiber and nanofiber can significantly influence sustainability efforts by minimizing plastic waste and supporting eco-friendly manufacturing processes.

Cost Analysis: Microfiber vs Nanofiber Products

Microfiber products typically cost less than nanofiber alternatives due to simpler manufacturing processes and widely available raw materials. Nanofiber products demand advanced technology and precision, driving higher production expenses and retail prices. Your choice between microfiber and nanofiber depends on balancing cost against performance benefits such as filtration efficiency or durability.

Choosing the Right Fiber: Factors to Consider

Choosing between microfiber and nanofiber depends on factors such as particle filtration efficiency, durability, and application needs; nanofiber offers superior filtration for fine particles due to its smaller fiber diameter, while microfiber tends to be more robust and cost-effective. Consider your specific use case, whether it's air or liquid filtration, cleaning, or protective fabrics, as nanofibers excel in precision filtration but may require more careful handling. Your decision should balance performance requirements with budget constraints and maintenance preferences to ensure optimal fiber functionality.

Microfiber vs Nanofiber Infographic

libmatt.com

libmatt.com