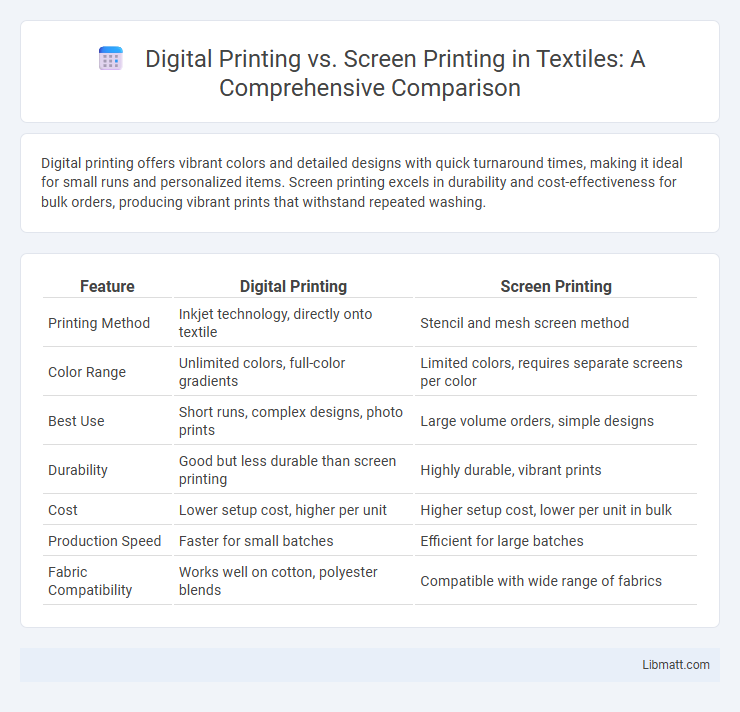

Digital printing offers vibrant colors and detailed designs with quick turnaround times, making it ideal for small runs and personalized items. Screen printing excels in durability and cost-effectiveness for bulk orders, producing vibrant prints that withstand repeated washing.

Table of Comparison

| Feature | Digital Printing | Screen Printing |

|---|---|---|

| Printing Method | Inkjet technology, directly onto textile | Stencil and mesh screen method |

| Color Range | Unlimited colors, full-color gradients | Limited colors, requires separate screens per color |

| Best Use | Short runs, complex designs, photo prints | Large volume orders, simple designs |

| Durability | Good but less durable than screen printing | Highly durable, vibrant prints |

| Cost | Lower setup cost, higher per unit | Higher setup cost, lower per unit in bulk |

| Production Speed | Faster for small batches | Efficient for large batches |

| Fabric Compatibility | Works well on cotton, polyester blends | Compatible with wide range of fabrics |

Introduction to Digital Printing and Screen Printing

Digital printing uses advanced inkjet technology to directly apply designs onto various materials with high precision and vibrant colors, ideal for short runs and complex images. Screen printing involves creating a stencil on a mesh screen to apply layers of ink, providing durability and rich color saturation, especially effective for large batches and simple designs. Understanding these techniques helps you choose the best method based on project volume, detail, and fabric type.

How Digital Printing Works

Digital printing works by directly transferring a digital image onto a substrate using inkjet or laser technology, enabling high-resolution and full-color outputs without the need for printing plates. This process allows for rapid production and easy customization, making it ideal for small runs and complex designs with multiple colors. Your designs are precisely reproduced with detailed color gradients and sharp lines, ensuring vibrant and accurate prints on various materials.

How Screen Printing Works

Screen printing involves creating a stencil, or screen, which is then used to apply layers of ink directly onto the printing surface through a mesh. Each color requires a separate screen, allowing for vibrant and durable prints ideal for bulk orders and high-quality designs. You can achieve precise, long-lasting results with screen printing, especially on materials like fabric, wood, and metal.

Print Quality Comparison

Digital printing offers high-resolution prints with intricate details and vibrant color gradients, ideal for complex designs and photographic images. Screen printing provides superior durability and color solidity, especially on dark fabrics, with thicker ink layers that withstand multiple washes. While digital printing excels in precision and color variety, screen printing remains preferred for bulk orders demanding long-lasting, vivid prints.

Cost Analysis: Digital vs. Screen Printing

Digital printing typically offers lower setup costs, making it cost-effective for small to medium print runs, while screen printing involves higher initial expenses due to screen preparation but becomes more economical for large volume orders. Your choice depends on the order size; digital printing allows for quick, customizable prints with minimal waste, whereas screen printing's durability and vibrant ink quality justify the higher upfront investment for bulk production. Understanding these cost dynamics ensures you select the most budget-friendly method tailored to your project scale and quality requirements.

Turnaround Time Differences

Digital printing offers significantly faster turnaround times compared to screen printing, as it requires minimal setup and can produce prints immediately after design upload. Screen printing involves longer preparation due to stencil creation and color separations, making it less ideal for urgent orders or small runs. Your business benefits from digital printing when speed and quick delivery are critical factors.

Design Flexibility and Customization

Digital printing offers unparalleled design flexibility with the ability to produce intricate, multicolored patterns and photographic-quality images directly from digital files, enabling infinite customization options. Screen printing requires separate screens for each color, limiting complexity and color variation, making it more suitable for simpler designs and bulk orders. Customization in digital printing excels in small runs and one-off prints, whereas screen printing is cost-effective for large volumes with consistent designs.

Environmental Impact Assessment

Digital printing produces less waste and consumes fewer chemicals compared to screen printing, reducing its environmental footprint significantly. Screen printing requires large amounts of water and generates more hazardous waste due to the use of inks and cleaning solvents. Life cycle assessments consistently show digital printing as the more sustainable option, especially for small runs and customized products.

Best Use Cases for Each Printing Method

Digital printing excels in producing high-detail, multicolor designs on small to medium runs, making it ideal for customized apparel, promotional products, and prototypes. Screen printing is best suited for large-volume orders with simple designs or limited color palettes, offering durability and vibrant colors on textiles like t-shirts and hoodies. Your choice depends on factors such as print complexity, order size, and desired longevity of the final product.

Choosing the Right Printing Technique

Digital printing offers detailed, vibrant designs ideal for small to medium runs with complex color variations, while screen printing excels in durability and cost-efficiency for large quantities and simple, bold designs. Your decision should consider factors like order volume, color complexity, fabric type, and budget constraints to ensure optimal results. Prioritizing these aspects helps you select the most effective printing technique for your project's needs.

Digital printing vs Screen printing Infographic

libmatt.com

libmatt.com