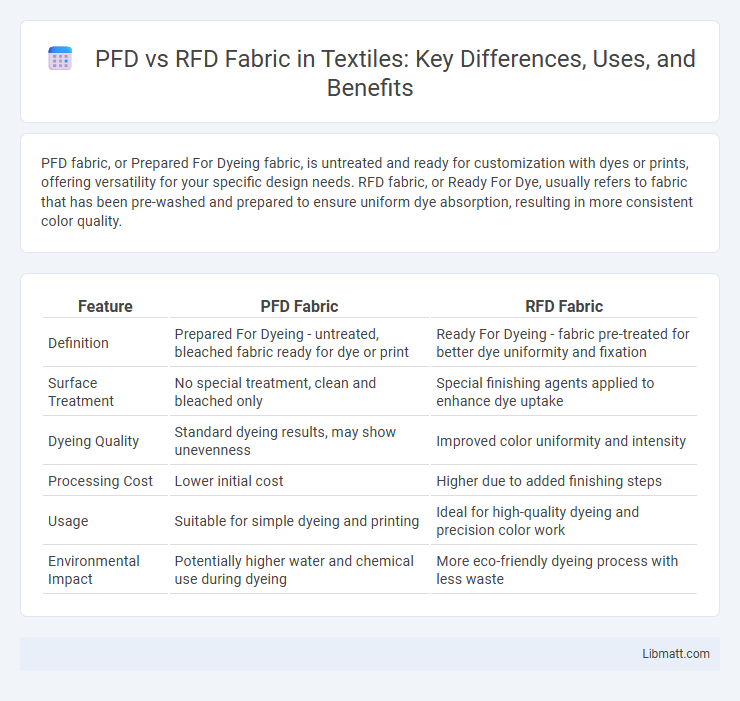

PFD fabric, or Prepared For Dyeing fabric, is untreated and ready for customization with dyes or prints, offering versatility for your specific design needs. RFD fabric, or Ready For Dye, usually refers to fabric that has been pre-washed and prepared to ensure uniform dye absorption, resulting in more consistent color quality.

Table of Comparison

| Feature | PFD Fabric | RFD Fabric |

|---|---|---|

| Definition | Prepared For Dyeing - untreated, bleached fabric ready for dye or print | Ready For Dyeing - fabric pre-treated for better dye uniformity and fixation |

| Surface Treatment | No special treatment, clean and bleached only | Special finishing agents applied to enhance dye uptake |

| Dyeing Quality | Standard dyeing results, may show unevenness | Improved color uniformity and intensity |

| Processing Cost | Lower initial cost | Higher due to added finishing steps |

| Usage | Suitable for simple dyeing and printing | Ideal for high-quality dyeing and precision color work |

| Environmental Impact | Potentially higher water and chemical use during dyeing | More eco-friendly dyeing process with less waste |

Understanding PFD and RFD Fabrics

PFD (Prepared For Dyeing) fabric is untreated, allowing you to customize colors and finishes according to specific design requirements, whereas RFD (Ready For Dyeing) fabric has undergone pre-treatment to ensure consistent dye absorption and color fastness. Understanding the differences helps optimize fabric selection for manufacturing processes, improving dyeing efficiency and final product quality. Choosing between PFD and RFD impacts production timelines, cost, and the vibrancy of your textile creations.

What Does PFD Fabric Mean?

PFD fabric stands for "Prepared For Dyeing," indicating that the textile has undergone initial processing to remove impurities and is ready to be dyed or printed with colors. This treatment enhances dye absorption, ensuring uniform color application and improved fabric performance. PFD fabrics commonly serve as a blank canvas in textile manufacturing, enabling customization through various dyeing and printing techniques.

What Is RFD Fabric?

RFD fabric, or Ready For Dye fabric, is a textile specifically manufactured to undergo direct dyeing processes without requiring additional bleaching or scouring. This fabric maintains natural fibers like cotton or blends in a clean, untreated state to ensure optimal dye absorption and vibrant color results. RFD fabric is preferred in textile production for its efficiency in achieving consistent coloration while preserving fabric strength and texture.

Key Differences Between PFD and RFD

PFD (Prepared for Dyeing) fabric is unbleached and untreated, retaining its natural color and texture, while RFD (Ready for Dyeing) fabric undergoes preliminary scouring and bleaching to remove impurities and natural oils, resulting in a cleaner surface. PFD fabric requires more extensive processing during dyeing, whereas RFD fabric allows for more consistent dye absorption and better color uniformity. The choice between PFD and RFD fabric impacts manufacturing efficiency, dye quality, and final product appearance.

Manufacturing Process: PFD vs RFD

PFD (Prepared for Dyeing) fabric undergoes preliminary treatments such as desizing, scouring, and bleaching to remove impurities, preparing the textile for uniform dye absorption. In contrast, RFD (Ready for Dyeing) fabric is fully processed with these preparatory steps completed, ensuring it is clean and free from natural oils or substances that interfere with dyeing. Choosing RFD fabric streamlines your manufacturing process by eliminating initial fabric preparation, making it ideal for quicker production cycles.

Common Uses of PFD Fabrics

PFD (Prepared For Dye) fabrics are commonly used in textile manufacturing for apparel, home textiles, and fashion accessories, as they provide a blank canvas ready for custom dyeing and printing processes. These fabrics are ideal for producing vibrant colors and unique patterns, making them a preferred choice for designers and manufacturers aiming to create tailored textile products. Your projects benefit from PFD fabrics when seeking versatile, high-quality materials that can be easily customized to meet specific aesthetic and functional requirements.

Popular Applications of RFD Fabrics

RFD (Ready For Dye) fabrics are widely used in the fashion and textile industries for custom garment production and textile printing due to their undyed, scoured, and bleached surface which ensures optimal dye absorption and color vibrancy. These fabrics are popular for creating high-quality, richly colored apparel, home textiles, and promotional materials. Markets such as sportswear, interior decor, and fast fashion frequently utilize RFD fabrics to achieve precise color matching and superior print clarity.

Advantages and Disadvantages: PFD vs RFD

PFD fabric offers superior water resistance and quicker drying times compared to RFD fabric, making it ideal for outdoor and performance wear. RFD fabric is generally more cost-effective and allows for greater customization through dyeing and finishing processes but lacks the inherent durability and moisture management properties of PFD. Choosing between PFD and RFD depends on balancing budget constraints with the need for technical fabric performance and longevity.

How to Choose: PFD or RFD for Your Project

Choosing between PFD (Prepared for Dyeing) and RFD (Ready for Dyeing) fabric depends on the specific needs of your project regarding customization and lead time. PFD fabrics offer a raw, untreated base ideal for projects requiring unique dyeing or printing processes, granting extensive control over color and finish; RFD fabrics come pre-treated with chemicals that facilitate faster dye absorption, reducing production time and ensuring consistent results. Assessing your production timeline, desired fabric characteristics, and budget will help determine whether the flexibility of PFD or the convenience of RFD best suits your project objectives.

Frequently Asked Questions About PFD and RFD

PFD (Prepared For Dyeing) fabric is chemically treated and ready to absorb dyes uniformly, while RFD (Ready For Dyeing) fabric has undergone preliminary treatments such as desizing and scouring but may require additional processes for optimal dye uptake. Your choice between PFD and RFD depends on specific manufacturing needs, cost considerations, and desired fabric quality. Common questions include differences in processing time, compatibility with various dye types, and impact on final fabric hand feel and color fastness.

PFD vs RFD fabric Infographic

libmatt.com

libmatt.com