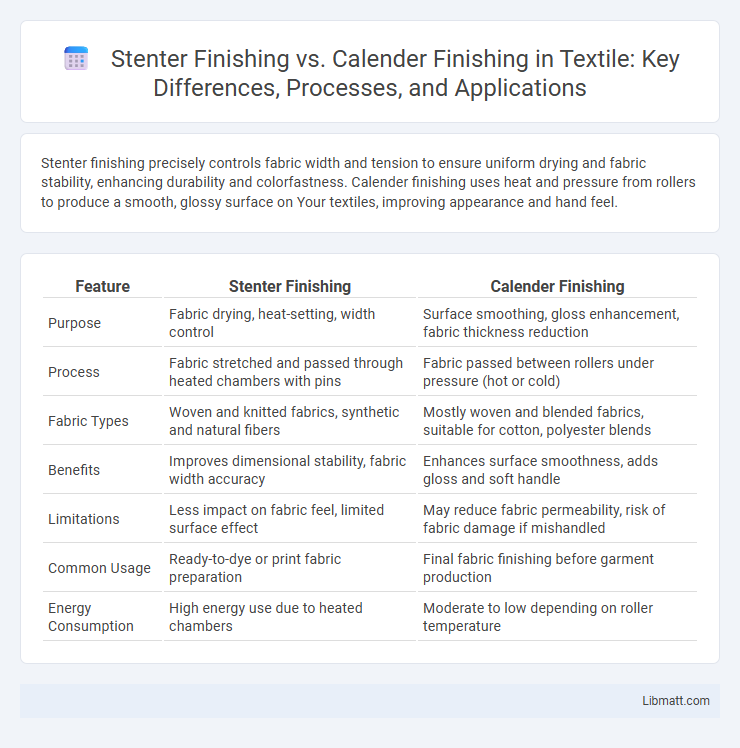

Stenter finishing precisely controls fabric width and tension to ensure uniform drying and fabric stability, enhancing durability and colorfastness. Calender finishing uses heat and pressure from rollers to produce a smooth, glossy surface on Your textiles, improving appearance and hand feel.

Table of Comparison

| Feature | Stenter Finishing | Calender Finishing |

|---|---|---|

| Purpose | Fabric drying, heat-setting, width control | Surface smoothing, gloss enhancement, fabric thickness reduction |

| Process | Fabric stretched and passed through heated chambers with pins | Fabric passed between rollers under pressure (hot or cold) |

| Fabric Types | Woven and knitted fabrics, synthetic and natural fibers | Mostly woven and blended fabrics, suitable for cotton, polyester blends |

| Benefits | Improves dimensional stability, fabric width accuracy | Enhances surface smoothness, adds gloss and soft handle |

| Limitations | Less impact on fabric feel, limited surface effect | May reduce fabric permeability, risk of fabric damage if mishandled |

| Common Usage | Ready-to-dye or print fabric preparation | Final fabric finishing before garment production |

| Energy Consumption | High energy use due to heated chambers | Moderate to low depending on roller temperature |

Introduction to Textile Finishing Processes

Stenter finishing and calender finishing are essential textile finishing processes that enhance fabric quality and performance. Stenter finishing involves controlled stretching and heat setting to stabilize fabric dimensions and improve texture, while calender finishing uses high pressure rollers to smooth and add luster or special effects to the fabric surface. Your choice between these finishing methods depends on the desired fabric properties such as durability, appearance, and hand feel.

Overview of Stenter Finishing

Stenter finishing is a textile process that uses adjustable pins and heated chambers to stretch and dry fabrics, ensuring precise width control and smooth surface texture. This method enhances fabric stability, dimensional accuracy, and improves properties such as color fixation and softness. Stenter finishing is essential for synthetic and blended fabrics, delivering consistent quality for various textile applications.

Overview of Calender Finishing

Calender finishing is a textile process that uses a series of heated rollers to smooth, glaze, or emboss fabric, enhancing its surface texture and appearance. This method improves fabric softness, sheen, and dimensional stability, making it ideal for applications where a polished, refined finish is desired. Your fabrics gain a consistent, high-quality finish suitable for apparel, home textiles, and technical fabrics through precise temperature and roller pressure control.

Key Differences Between Stenter and Calender Finishing

Stenter finishing involves stretching fabric in the width direction while drying to achieve dimensional stability and desired width, whereas calender finishing uses heated rollers to smooth, glaze, or emboss fabric surfaces, enhancing texture and appearance. Stenter machines offer precise temperature and tension control for uniform drying, making them ideal for synthetic and coated fabrics, while calender machines focus on surface finish improvements for woven, knit, and nonwoven textiles. The key difference lies in stenter's emphasis on fabric width control and drying, contrasted with calender's role in altering surface properties through pressure and heat.

Process Workflow: Stenter vs Calender

Stenter finishing uses heated frames that stretch and dry fabric, maintaining precise width and removing wrinkles through tension control, ideal for synthetic and woven textiles. Calender finishing involves passing fabric through heated rollers to smooth, coat, or impart gloss, enhancing surface texture primarily for fabrics requiring a polished appearance. Your choice depends on whether dimensional stability and drying (stenter) or surface smoothness and sheen (calender) are prioritized in your textile production workflow.

Impact on Fabric Properties

Stenter finishing enhances fabric dimensional stability and improves dye fixation by stretching and heat-setting textiles, resulting in reduced shrinkage and enhanced color fastness. In contrast, calender finishing smooths and compresses fabric surfaces through heated rollers, increasing fabric gloss and density but potentially reducing permeability and stretchability. Choosing between stenter and calender finishing depends on the desired fabric properties, such as elasticity, surface texture, and moisture management.

Applications and Suitable Fabric Types

Stenter finishing is ideal for synthetic and blended fabrics requiring dimensional stability and precise width control, commonly used in apparel, home textiles, and technical fabrics. Calender finishing suits woven and knitted fabrics such as cotton, silk, and polyester blends, enhancing surface smoothness and imparting a glossy finish for products like shirting, upholstery, and drapery. Both processes optimize functional and aesthetic properties, with stenter providing heat setting and drying, while calender emphasizes fabric surface texture and luster.

Advantages and Limitations

Stenter finishing offers precise width control and fabric drying, enhancing dimensional stability and fabric quality, but it requires higher energy consumption and equipment costs. Calender finishing provides a smooth, glossy surface and improved fabric luster with faster processing times, yet it may reduce fabric thickness and breathability. Choosing between stenter and calender finishing depends on the desired fabric properties, production efficiency, and energy considerations.

Cost and Energy Efficiency Comparison

Stenter finishing generally incurs higher operational costs due to its complex machinery and extended processing time, whereas calender finishing offers lower energy consumption through rapid heat and pressure application. Energy efficiency in calender finishing is enhanced by its ability to quickly produce smooth, glossy textile surfaces with minimal thermal loss, making it more cost-effective for large-scale production. However, stenter finishing delivers superior fabric dimensional stability, which can justify its higher energy expenditure in applications requiring precision.

Choosing the Right Finishing Method

Selecting the right fabric finishing method depends on desired fabric qualities and end-use applications. Stenter finishing is ideal for controlling fabric width, enhancing durability, and applying treatments such as water repellency or flame retardancy. Calender finishing excels in producing smooth, glossy surfaces and improved fabric hand, making it suitable for textiles requiring aesthetic enhancement and softness.

Stenter Finishing vs Calender Finishing Infographic

libmatt.com

libmatt.com