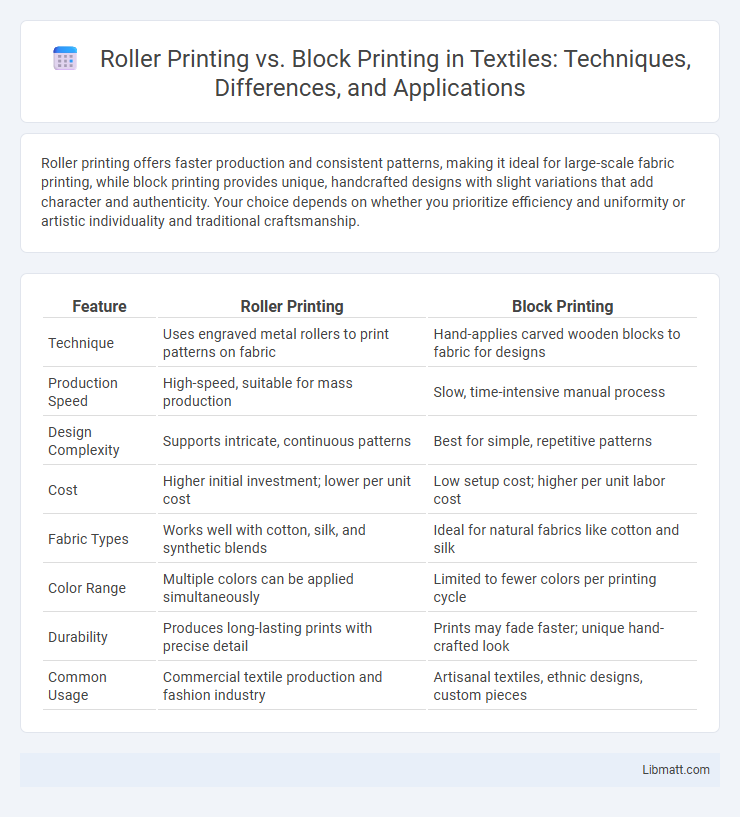

Roller printing offers faster production and consistent patterns, making it ideal for large-scale fabric printing, while block printing provides unique, handcrafted designs with slight variations that add character and authenticity. Your choice depends on whether you prioritize efficiency and uniformity or artistic individuality and traditional craftsmanship.

Table of Comparison

| Feature | Roller Printing | Block Printing |

|---|---|---|

| Technique | Uses engraved metal rollers to print patterns on fabric | Hand-applies carved wooden blocks to fabric for designs |

| Production Speed | High-speed, suitable for mass production | Slow, time-intensive manual process |

| Design Complexity | Supports intricate, continuous patterns | Best for simple, repetitive patterns |

| Cost | Higher initial investment; lower per unit cost | Low setup cost; higher per unit labor cost |

| Fabric Types | Works well with cotton, silk, and synthetic blends | Ideal for natural fabrics like cotton and silk |

| Color Range | Multiple colors can be applied simultaneously | Limited to fewer colors per printing cycle |

| Durability | Produces long-lasting prints with precise detail | Prints may fade faster; unique hand-crafted look |

| Common Usage | Commercial textile production and fashion industry | Artisanal textiles, ethnic designs, custom pieces |

Introduction to Roller Printing and Block Printing

Roller printing uses engraved cylindrical rollers to apply continuous patterns on fabric, enabling high-speed production with precise, repeatable designs ideal for large-scale textile manufacturing. Block printing relies on hand-carved wooden blocks pressed onto fabric to create intricate, unique patterns, often showcasing traditional craftsmanship and slower, artisanal production processes. Both methods offer distinctive aesthetic qualities and are chosen based on desired fabric texture, design complexity, and production volume.

Historical Background of Printing Techniques

Roller printing, developed in the late 18th century during the Industrial Revolution, revolutionized textile production by enabling faster and more consistent fabric designs compared to traditional hand methods. Block printing, with origins tracing back over 1,000 years to ancient China and India, relies on hand-carved wooden blocks to stamp patterns onto textiles, emphasizing craftsmanship and intricate detail. The transition from block printing to roller printing marked a significant shift towards mechanization and mass production in the textile industry.

How Roller Printing Works

Roller printing uses engraved cylindrical rollers to transfer dye onto fabric, producing intricate patterns with precise repetition and high-speed efficiency. Each roller applies a specific color, allowing for multi-colored designs in a single pass, making it ideal for large-scale textile production. Your choice of roller printing ensures consistent quality and faster output compared to traditional block printing methods.

How Block Printing Works

Block printing involves carving designs into wooden blocks, which are then dipped in dye and pressed onto fabric to create patterns. This traditional technique allows for intricate, hand-crafted motifs by aligning multiple blocks for different colors or designs. Your choice of block printing ensures unique, textured prints with artisanal appeal compared to the faster, machine-driven roller printing process.

Materials Used in Each Printing Method

Roller printing primarily uses engraved metal cylinders and textile dyes suitable for mass production on fabrics like cotton and silk, enabling precise and repetitive patterns with vibrant colors. Block printing involves hand-carved wooden blocks and natural or synthetic inks, often applied to thicker fabrics such as cotton, linen, or wool, offering a more artisanal and textured finish. You can choose roller printing for efficiency and detail, while block printing provides a handcrafted, traditional aesthetic.

Speed and Efficiency Comparison

Roller printing offers significantly higher speed and efficiency compared to block printing, producing intricate patterns at rates up to 60 yards per minute, while block printing processes require manual labor and are much slower, typically limited to a few yards per hour. Automation in roller printing reduces human error and increases consistency, making it ideal for large-scale textile production. Block printing remains valuable for artisanal and custom designs but cannot match the rapid throughput and scalability of roller printing methods.

Design Complexity and Versatility

Roller printing enables high design complexity and versatility by allowing intricate patterns and multiple color layers to be printed rapidly on fabric with precise registration. Block printing, while rich in traditional appeal, is limited by the manual process to simpler designs and fewer color variations, often resulting in less uniformity across prints. The mechanized nature of roller printing supports large-scale production of detailed and diverse textile patterns, making it ideal for contemporary fashion and industrial applications.

Cost Implications and Production Scale

Roller printing offers lower cost per unit and higher production speed compared to block printing, making it ideal for large-scale textile manufacturing. Block printing involves higher labor costs and slower output, limiting its cost-efficiency for mass production but providing unique artisanal value. Manufacturing facilities aiming for high volume and budget-friendly processes typically prefer roller printing over the labor-intensive block printing method.

Environmental Impact and Sustainability

Roller printing reduces water and energy consumption compared to traditional block printing, minimizing waste through automated precision, making it more environmentally sustainable for large-scale production. Block printing relies on manual processes that can lead to higher water usage and fabric waste, but it utilizes natural dyes and biodegradable materials, supporting eco-friendly craftsmanship. Both methods benefit from using organic inks and sustainable fabrics to further reduce their ecological footprints in textile production.

Choosing the Right Printing Method

Choosing the right printing method depends on the scale and detail of your project, where roller printing excels in producing high-volume, consistent patterns quickly, while block printing offers unique, handcrafted designs with intricate details. Roller printing is ideal for commercial textile production, ensuring uniformity and speed, whereas block printing suits customized, artisanal creations that highlight craftsmanship and texture. Your choice should align with the desired aesthetic, production speed, and budget considerations to achieve the best results.

Roller Printing vs Block Printing Infographic

libmatt.com

libmatt.com